By Vishay 112

Aluminum electrolytic capacitors are polarized electrolytic capacitors. The anode electrode (+) is made of aluminum foil with an etched surface. The aluminum foil is anodized and covered with a thin layer of aluminum oxide insulation. dielectric. The aluminum oxide is covered with a non-solid electrolyte, which is the cathode (-) of the capacitor.Aluminum Electrolytic Capacitors

An aluminum electrolytic capacitor is made of an aluminum cylinder as the negative electrode, which is filled with a liquid electrolyte, and a bent aluminum strip is inserted as the positive electrode. It also needs to be treated with DC voltage to form a layer of oxide film on the positive electrode as a medium.Aluminum Electrolytic Capacitors - Screw Term

Ⅰ. Basic structure of aluminum electrolytic capacitor

Aluminum electrolytic capacitors are composed of Packaging Material, Dielectric Layer, Electrolyte, Anode and Cathode Plates.

Packaging Material: Aluminum electrolytic capacitors are usually packaged with a metal case for protection and mechanical support. The housing is usually made of metal or plastic material and has leads or terminals for connection to the circuit.Aluminum Electrolytic Capacitors - Snap In

Dielectric Layer: The dielectric layer is a layer of insulating material in aluminum electrolytic capacitors, usually formed of aluminum oxide. A dielectric layer sits between the anode and cathode, separating the two plates while allowing the electric field to pass through.

Electrolyte: Electrolyte is an important component in aluminum electrolytic capacitors. It is a highly conductive liquid that usually contains boric acid or sulfate solutions. The electrolyte provides an ionically conductive path between the anode and cathode, allowing the capacitor to charge and discharge.

Anode and Cathode Plates: The plates of aluminum electrolytic capacitors are made of aluminum foil, one of which is oxidized to become Anode, and the other plate is Cathode. The aluminum oxide layer on the anode has a high dielectric constant and electrolytic properties.Aluminum Electrolytic Capacitors - Radial Leaded

Ⅱ. Classification of Aluminum Electrolytic Capacitors

1. Aluminum electrolytic capacitors with non-solid (liquid, wet) electrolytes

Aluminum electrolytic capacitors with non-solid (liquid, wet) electrolytes are usually called Wet Aluminum Electrolytic Capacitors. These capacitors use a liquid electrolyte soaked between aluminum foil plates separated by a polyethylene film or paper separator.

Aluminum electrolytic capacitors without solid electrolytes are the cheapest capacitors and have the widest range of sizes, capacities, and voltage ratings.

Features:

Wet-type aluminum electrolytic capacitors use a liquid electrolyte, usually a boric acid or sulfate solution. This liquid electrolyte has high electrical conductivity, allowing the capacitor to charge and discharge efficiently.Aluminum Electrolytic Capacitors - Leaded

Wet-type aluminum electrolytic capacitors are usually packaged with a metal case for mechanical protection and lead connections.

The anode and cathode of wet-type aluminum electrolytic capacitors are made of aluminum foil, and the surface area is increased by methods such as coating. The two plates are separated by polyethylene film or paper diaphragm to prevent direct short circuit.

2. Polymer Capacitors

A Polymer Capacitor is a type of electrolytic capacitor whose electrolyte uses a polymer gel instead of a traditional liquid electrolyte. It has high capacitance, low ESR and ESL, long life, and good temperature stability. Polymer capacitors are used in many applications as a high performance alternative to traditional liquid electrolytic capacitors.

Polymer capacitors are divided into the following categories:

Organic Electrolyte Aluminum Capacitor: This capacitor uses an organic electrolyte and aluminum foil plates for low ESR, low leakage current, and high temperature stability. They are suitable for high-frequency circuits, communication equipment and automation equipment and other fields.

Aluminum Polymer Capacitor: Aluminum polymer capacitors combine the high capacity of aluminum electrolytic capacitors with the low ESR and long life characteristics of polymer capacitors. They feature high capacitance, low ESR, and low leakage current, and are suitable for high-performance electronics and power modules.

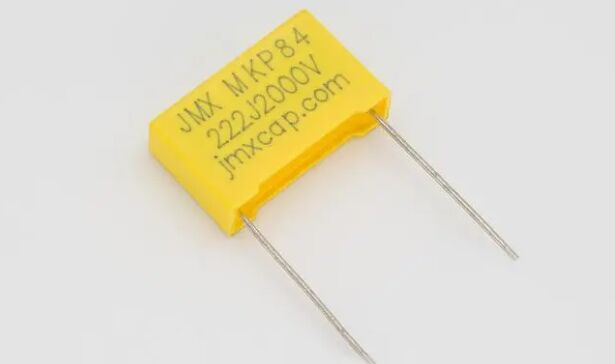

Polyester Film Capacitor: Polyester film capacitors use polyester as the dielectric and have high capacitance and good temperature stability. They are widely used in fields such as consumer electronics, communication equipment, and power supply circuits.

Polypropylene Film Capacitor: Polypropylene film capacitors use polypropylene as the dielectric and generally have high withstand voltage capabilities and stable capacitance values, suitable for high-precision and high-frequency applications.

3. Solid Aluminum Capacitors

A Solid Aluminum Capacitor is a special type of electrolytic capacitor that uses a solid electrolyte instead of the traditional liquid electrolyte. Solid aluminum capacitors typically have high capacitance, low ESR and ESL, long life, and good temperature stability.Aluminum Electrolytic Capacitors - SMD

advantage:

Long life: Solid aluminum capacitors typically have a long life and outlast traditional liquid electrolytic capacitors.

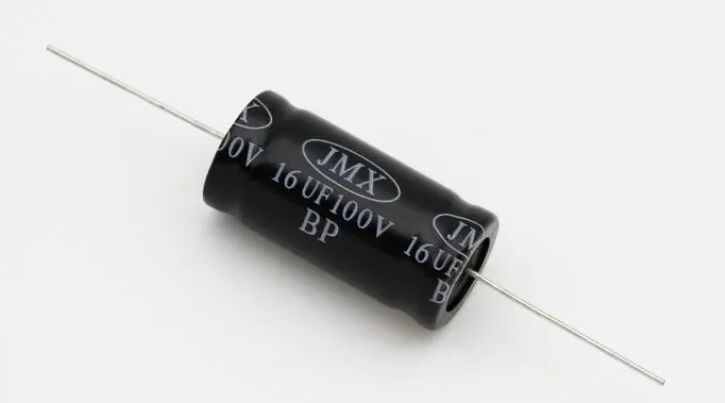

Low ESR and Low Leakage Current: Solid aluminum capacitors have low equivalent series resistance (ESR) and leakage current, which help reduce power loss and improve efficiency.Aluminum Electrolytic Capacitors - Axial Leaded

High temperature stability: Solid aluminum capacitors have better temperature stability, can work in high temperature environments, and are not easily damaged at high temperatures.

Solid aluminum capacitors are divided into solid inorganic electrolytic aluminum capacitors and solid inorganic electrolytic aluminum capacitors.

Solid Inorganic Electrolyte Aluminum Capacitor: This capacitor uses a solid inorganic electrolyte such as aluminum oxide (Al2O3) as the electrolyte. They have high capacitance value and low ESR, suitable for high-performance electronic equipment and power modules.

Solid Organic Electrolyte Aluminum Capacitor: This capacitor uses a solid organic electrolyte as the electrolyte, which has low ESR, low leakage current, and high temperature stability. They are suitable for high-frequency circuits, communication equipment and automation equipment and other fields.

Ⅲ.Application Guidelines for Aluminum Electrolytic Capacitors

1. Operating temperature range: Consider the operating temperature range of an aluminum electrolytic capacitor to ensure it can function properly in the expected operating environment. Excessively high or low temperatures may affect the performance and life of the capacitor.

2. Capacity selection: select the appropriate capacitance value according to the application requirements. Larger capacitance values provide more energy storage capability, but also take up more space and cost. Make sure the capacitance of the selected capacitor meets the requirements of the circuit.

3. Voltage rating: When selecting an aluminum electrolytic capacitor, make sure that its voltage rating is higher than the maximum working voltage in the circuit. Excessive voltage may damage or rupture the capacitor.

4. Life and reliability: Know the life expectancy of aluminum electrolytic capacitors, and choose the appropriate life requirements according to the application needs. Certain applications may require long life and high reliability.

5. Capacitor life attenuation: The life of aluminum electrolytic capacitors will decay with time, especially in high temperature environments. For long-term use or applications requiring longer life, consider models with increased life and stability.

6.ESR: Consider the ESR value of the capacitor, especially for high frequency applications. Lower ESR values help reduce power loss and improve capacitor performance.

7. Capacitor polarity: Aluminum electrolytic capacitors are polar devices and must be connected correctly. Make sure to connect positive to positive and negative to negative. Incorrect polarity connections may result in capacitor damage or failure.

Ⅳ. Life of Aluminum Electrolytic Capacitors

Aluminum electrolytic capacitors will definitely go bad, it's just a matter of time. There are many reasons that affect the life of capacitors, such as overvoltage, reverse voltage, high temperature, rapid charging and discharging, etc. Under normal use, the biggest impact is temperature, because the higher the temperature, the faster the evaporation loss of the electrolyte. It should be noted that the temperature here does not refer to the ambient or surface temperature, but to the working temperature of the aluminum foil. Manufacturers usually mark the capacitor life and test temperature on the capacitor body.

Since the working temperature of the capacitor is increased by 10°C, the service life is halved, so don't think that the aluminum electrolytic capacitor with a service life of 2000 hours is better than that of 1000 hours, and pay attention to the test temperature to confirm the service life. Each manufacturer has calculation formulas for temperature and life, and when designing capacitors, it is necessary to refer to actual data for calculation. What needs to be understood is that to improve the life of aluminum electrolytic capacitors, the first is to reduce the operating temperature and keep away from heat sources on the PCB, and the second is to consider using capacitors with a higher maximum operating temperature, of course, the price will be higher.

The actual voltage that the electrolytic capacitor must withstand in the circuit cannot exceed its withstand voltage value. In the filter circuit, the withstand voltage value of the capacitor should not be less than 1.42 times the AC effective value. When using electrolytic capacitors, be careful not to reverse the positive and negative poles. Different circuits should use different types of capacitors. Mica and high-frequency ceramic capacitors can be used for the vibration circuit, paper-based, polyester, mica, electrolytic, and ceramic capacitors can be used for DC blocking, electrolytic capacitors can be used for filtering, and polyester, paper-based, ceramic, and electrolytic capacitors can be used for bypass.

Ⅴ. The charging process and discharging process of aluminum electrolytic capacitors and precautions

1. Charging process: Apply voltage on the positive pole (anode), and the negative pole (cathode) is grounded or connected to a lower potential to form an electric field. When a voltage is applied, positive ions in the electrolyte (such as Al3+) move toward the cathode, while electrons on the cathode flow back to the anode through an external circuit. Positive ions react with the cathode in the electrolyte, and form metal aluminum deposits on the surface of the cathode, and at the same time form charge accumulation.

2. Discharging process: disconnect the external power supply or reduce the power supply voltage, and cut off the power supply in the circuit. During discharge, charges are released from the capacitor back into the circuit, while the metal aluminum ions in the electrolyte redissolve into positive ions and electrons. The discharge process causes the capacitor's electric field to gradually weaken until the charge is released.

3. Precautions: During the charging process, the current should be gradually increased to avoid sudden application of excessive current; control the time of the charging and discharging process to avoid damage to the capacitor caused by excessive voltage or current stress; aluminum electrolytic capacitors The operating temperature range needs to be within the specified range to avoid the influence of excessive temperature on the performance of the capacitor.

Ⅵ. Extension of capacitor classification

In addition to aluminum electrolytic capacitors, there are also tantalum capacitors, safety capacitors, and niobium oxide capacitors.

Tantalum Capacitor: A Tantalum Capacitor is a type of capacitor that uses tantalum metal as the plate material and a tantalate such as potassium tantalate as the dielectric. Tantalum capacitors have high capacitance, low ESR (equivalent series resistance), low leakage current, and good frequency response characteristics.

Safety capacitors: also known as X and Y capacitors, are a specific type of capacitors designed for safety and noise suppression purposes in electrical circuits. They are primarily used to reduce electromagnetic interference (EMI), filter out high-frequency noise, and provide isolation and protection against electrical shocks.

Niobium oxide capacitor: is a type of capacitor that uses niobium oxide (Niobium Oxide) as a dielectric. Niobium oxide capacitors have medium capacitance and medium voltage ratings and are suitable for many electronic devices and applications.

Frequently Asked Questions

1. How to correctly connect the polarity of aluminum electrolytic capacitor?

On the shell of an aluminum electrolytic capacitor, there are usually marked positive (+) and negative (-). Sometimes the positive terminal may be marked with an arrow, plus sign, or other designation to indicate the positive terminal. Connect the positive terminal of the capacitor to the positive potential in the circuit. This could be the positive supply pin in the power circuit, or some other connection point with a positive potential. Use a suitable connection method, such as soldering, plugging or bolting, to ensure that the positive and negative connections are secure and the capacitor will not come loose.

2. What is the operating temperature range of aluminum electrolytic capacitors?

The life of an aluminum electrolytic capacitor can vary depending on several factors, including the quality of the capacitor, operating conditions, temperature, voltage stress, and the environment in which it is used. Generally speaking, the life of aluminum electrolytic capacitors is usually measured by the use time, usually between several thousand to tens of thousands of hours. Under normal operating conditions, the average life of an aluminum electrolytic capacitor is typically between 2,000 and 10,000 hours. However, some high-quality aluminum electrolytic capacitors may have a longer lifespan, which can reach or even exceed 20,000 hours. At the same time, factors such as the use of higher loads, high temperature, high voltage stress or unsuitable working environment may reduce the life of the capacitor.