By Amphenol LTW 186

There are many types of cables and are widely used. The following are the more common types of cables:

Ⅰ.Specialized Cables

Specialty cables are cables designed and manufactured for specific applications or industry needs. Have special functions, performance or characteristics to meet specific technical requirements and environmental conditions. Specialty cables usually have higher requirements and stricter specifications than ordinary cables.Specialized Cables

Specialty cables are designed and manufactured taking into account the needs of specific applications, such as temperature range, chemical resistance, mechanical strength, fire performance and electromagnetic compatibility. They usually comply with relevant national or international standards and norms to ensure their performance and safety.

Common specialty cable types are:

1. High-voltage cables: used to transmit high voltage and high current, such as power transmission and power grid applications.

2. High temperature cable: able to work in a high temperature environment, with high temperature resistant insulation and conductor materials.

3. Flame-retardant cable: it can inhibit the spread of fire and extinguish it automatically, and is suitable for places with high fire safety requirements.

4. Medical cables: used for medical equipment and medical devices, meeting the special requirements of the medical industry.

Ⅱ.RF Cable Assemblies

RF cable assemblies are connection and interface components for radio frequency applications. Usually composed of cables and connectors, it is used to transmit and connect radio frequency signals in radio frequency systems. They are used to build radio frequency systems, including wireless communications, broadcasting, satellite communications, radar, radio spectrum analyzers, and more.RF Cable Assemblies

Common RF cable assemblies are:

1.RF Cable Assemblies: RF cable assemblies are prefabricated RF cables, including a combination of connectors and cables. They provide convenient RF connectivity solutions and ensure reliability and performance of signal transmission.

2.RF Terminations: RF termination loads are used to absorb the energy of radio frequency signals to terminate circuits and avoid signal reflection and interference. They are commonly used for system testing, calibration, and to prevent signal reflections back to source equipment.

3.RF Connectors: RF connectors are plugs and sockets used to connect RF cables and devices. They provide reliable electrical connection and mechanical fixation to ensure the transmission and connection quality of RF signals.

4.RF Filters: RF filters are used to selectively pass or block RF signals within a specific frequency range. They are used to filter out noise, suppress interference, and enable frequency selection to ensure signal accuracy and quality.

Ⅲ.Ribbon Cables

A ribbon cable is a special type of cable whose planar structure consists of multiple conductors arranged in parallel, resembling a flat ribbon ribbon.Ribbon Cables

Key features of ribbon cables:

1. Planar structure: The conductors of the ribbon cable are arranged in parallel on the same plane to form a flat ribbon. This construction makes ribbon cables easier to manage and install during routing and connection.

2. Plugs and connectors: Both ends of the ribbon cable usually have corresponding plugs and connectors for connecting with equipment or circuit boards. These plugs and connectors match the construction of the ribbon cable, ensuring a reliable electrical connection.

3. Elasticity and flexibility: Ribbon cables are usually made of soft materials with a certain degree of elasticity and flexibility, making them adaptable to different installation environments and space constraints.

Ⅳ.IDC Cables

An IDC cable is a cable that is connected using an IDC plug. IDC plugs create a reliable electrical connection by cutting the cable insulation and inserting the wires directly into the cut slots in the plug.IDC Cables

Main features of IDC cables:

1. Quick connection: The cutting and insertion design of the IDC plug makes the connection process simple and fast. No need to unwire, strip insulation, or solder, simply insert the ribbon cable into the IDC plug to make the electrical connection.

2. IDC plug: The IDC plug has a series of cut slots arranged in parallel, each slot has a metal blade. When the cable is inserted into the plug, the blade cuts the cable insulation and makes an electrical connection with the wire.

3. Ribbon cable: IDC cables usually use a flat, ribbon cable structure in which multiple conductors are arranged in parallel on the same plane. The wires of the ribbon cable fit into the cut grooves of the IDC plug to ensure a reliable connection between the plug and the wires.

4. Internal wiring: IDC cables are often used for signal transmission inside the device and connection between circuit boards. They are widely used in the fields of computers, electronic equipment, communication equipment, etc., such as internal connections of hard disk drives, optical drives, printers, and other equipment.

Ⅴ.Sensor Cables

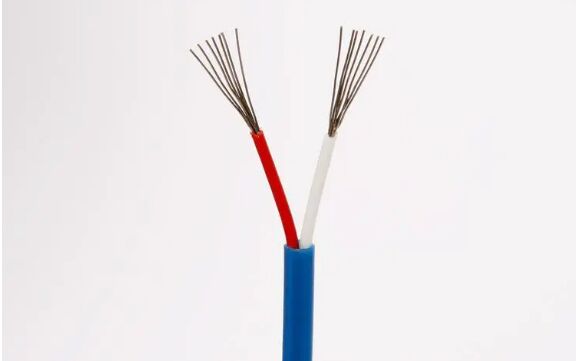

Sensor cables are cables designed to connect sensors to control systems or data acquisition equipment. Special cables for connecting sensors to control systems or data acquisition equipment. They are used to transmit the signals and data collected by the sensors, enabling them to communicate and interact with external devices.Sensor Cables

The characteristics and design of sensor cables are usually determined by the type of sensor, signal type, operating environment and application requirements.

Common sensor cable features:

1. Standard interface: The connection interface of the sensor cable is usually selected according to the specific sensor type and application requirements, such as plugs, connectors or custom interfaces.

2. Multi-core design: Some sensor systems may require multiple signal lines or power lines for connection, and sensor cables usually have a multi-core design to accommodate multiple wires.

3. High temperature resistance: Some sensor applications may face a high temperature environment, so the sensor cable needs to be able to withstand high temperature to ensure the reliability of signal transmission and the safety of the cable.

4. Waterproof and sealing: For sensor applications in outdoor or humid environments, sensor cables need to have good waterproof and sealing performance to prevent moisture and moisture from intruding into the cables and connectors.

Ⅵ.Actuator Cables

Actuator cables are cables specially used to connect actuators with control systems or power supplies. Actuator cables are used to transmit power, control signals and data, etc. to realize the control and operation of the actuator. The characteristics and design of the actuator cable are usually selected according to the type of actuator, power requirements, control signal type and environmental conditions, etc.Actuator Cables

The executive standard of the actuator cable:

1. National standards: Different countries may formulate their own actuator cable standards. For example, in Europe, the EN 50525 standard applies to low-voltage power cables and wires, some types of which may apply to actuator cables.

2. Industry standards: Specific industries may develop standards for actuator cables to meet specific application needs and safety requirements. For example, industries such as mechanical engineering, the automotive industry, manufacturing, etc. may have corresponding actuator cable standards.