ADuM240D/ADuM240E/ADuM241D/ADuM241E/ADuM242D/ADuM242E Data Sheet

Rev. A | Page 22 of 26

APPLICATIONS INFORMATION

PCB LAYOUT

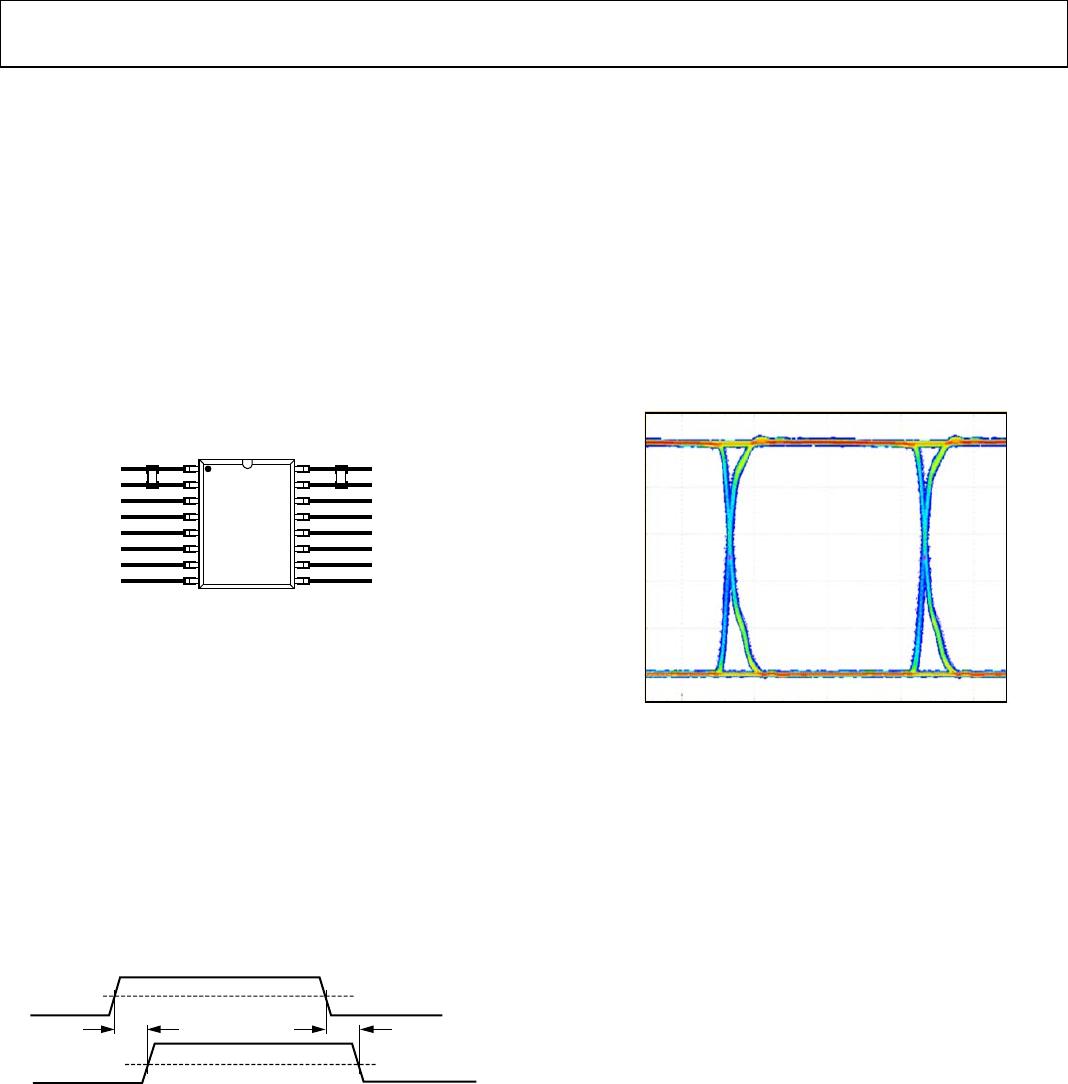

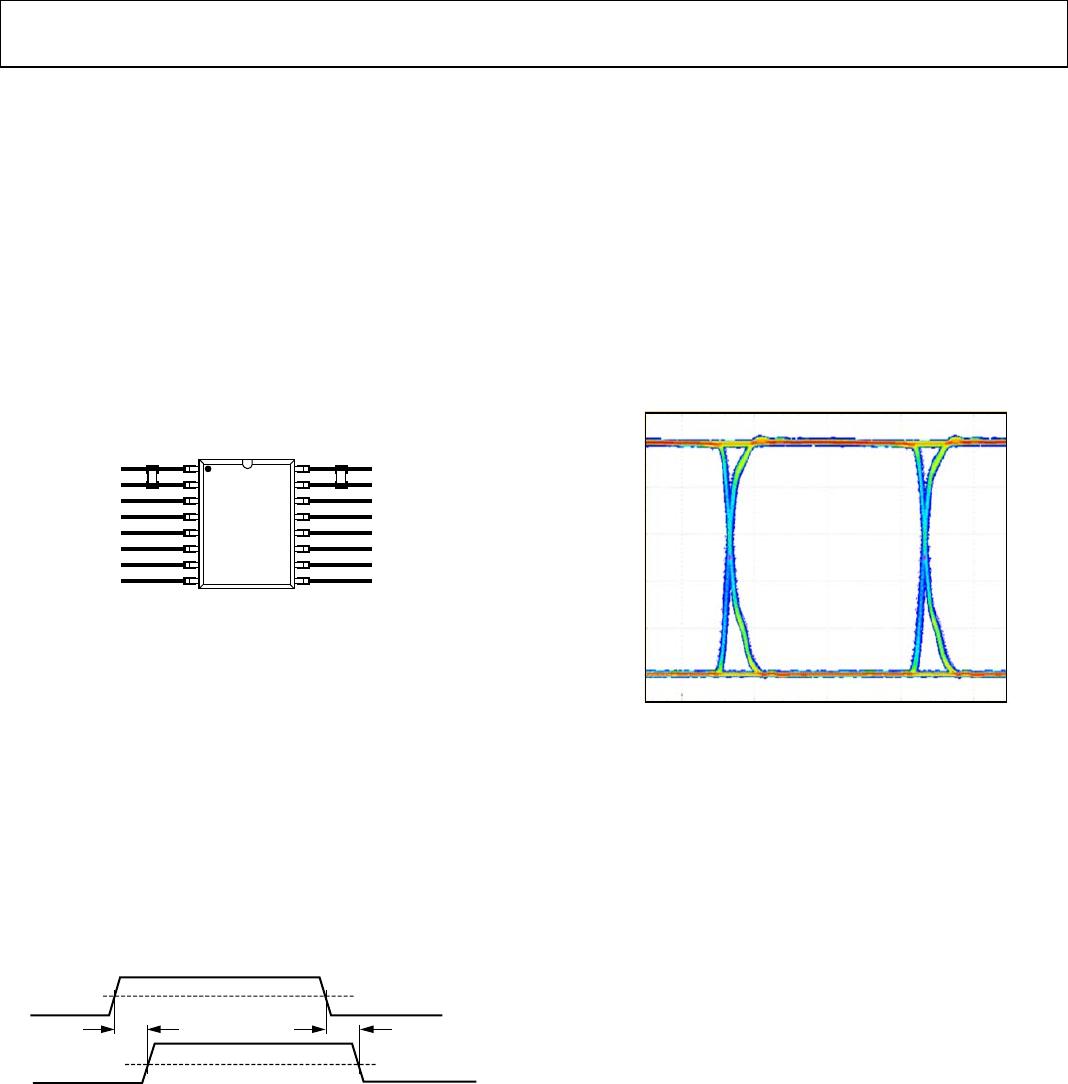

The ADuM240D/ADuM240E/ADuM241D/ADuM241E/

ADuM242D/ADuM242E digital isolators require no external

interface circuitry for the logic interfaces. Power supply bypassing

is strongly recommended at the input and output supply pins

(see Figure 21). Bypass capacitors are most conveniently connected

between Pin 1 and Pin 2 for V

DD1

and between Pin 15 and Pin 16

for V

DD2

. The recommended bypass capacitor value is between

0.01 μF and 0.1 μF. The total lead length between both ends of

the capacitor and the input power supply pin must not exceed

10 mm. Bypassing between Pin 1 and Pin 8 and between Pin 9

and Pin 16 must also be considered, unless the ground pair on

each package side is connected close to the package.

Figure 21. Recommended Printed Circuit Board Layout

In applications involving high common-mode transients, ensure

that board coupling across the isolation barrier is minimized.

Furthermore, design the board layout such that any coupling

that does occur equally affects all pins on a given component

side. Failure to ensure this can cause voltage differentials between

pins exceeding the Absolute Maximum Ratings of the device,

thereby leading to latch-up or permanent damage.

See the AN-1109 Application Note for board layout guidelines.

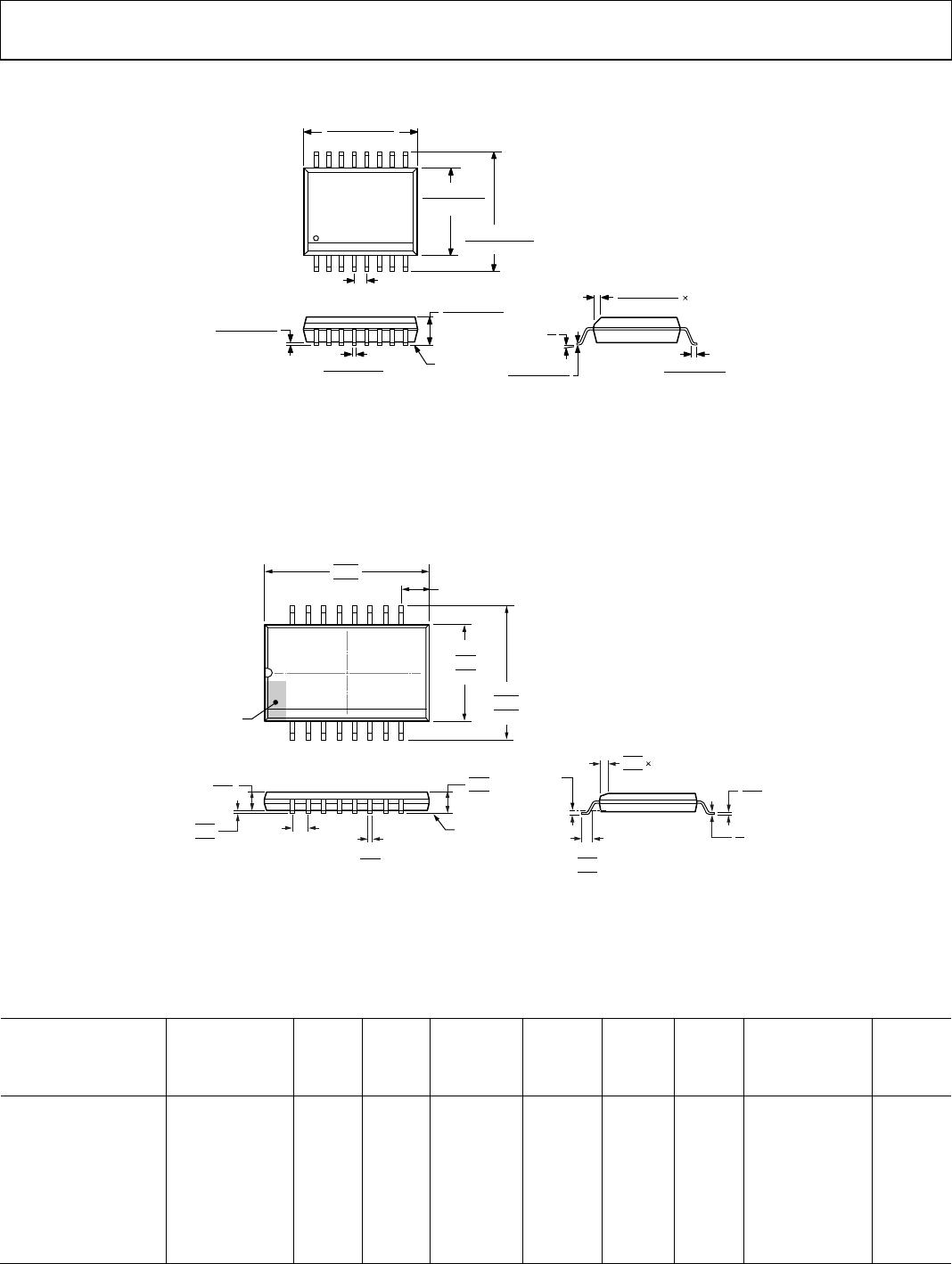

PROPAGATION DELAY RELATED PARAMETERS

Propagation delay is a parameter that describes the time

required for a logic signal to propagate through a component. The

propagation delay to a Logic 0 output may differ from the

propagation delay to a Logic 1 output.

Figure 22. Propagation Delay Parameters

Pulse width distortion is the maximum difference between these

two propagation delay values and is an indication of how

accurately the timing of the input signal is preserved.

Channel matching is the maximum amount the propagation

delay differs between channels within a single ADuM240D/

ADuM240E/ADuM241D/ADuM241E/ADuM242D/ADuM242E

component.

Propagation delay skew is the maximum amount the propagation

delay differs between multiple ADuM240D/ADuM240E/

ADuM241D/ADuM241E/ADuM242D/ADuM242E components

operating under the same conditions

JITTER MEASUREMENT

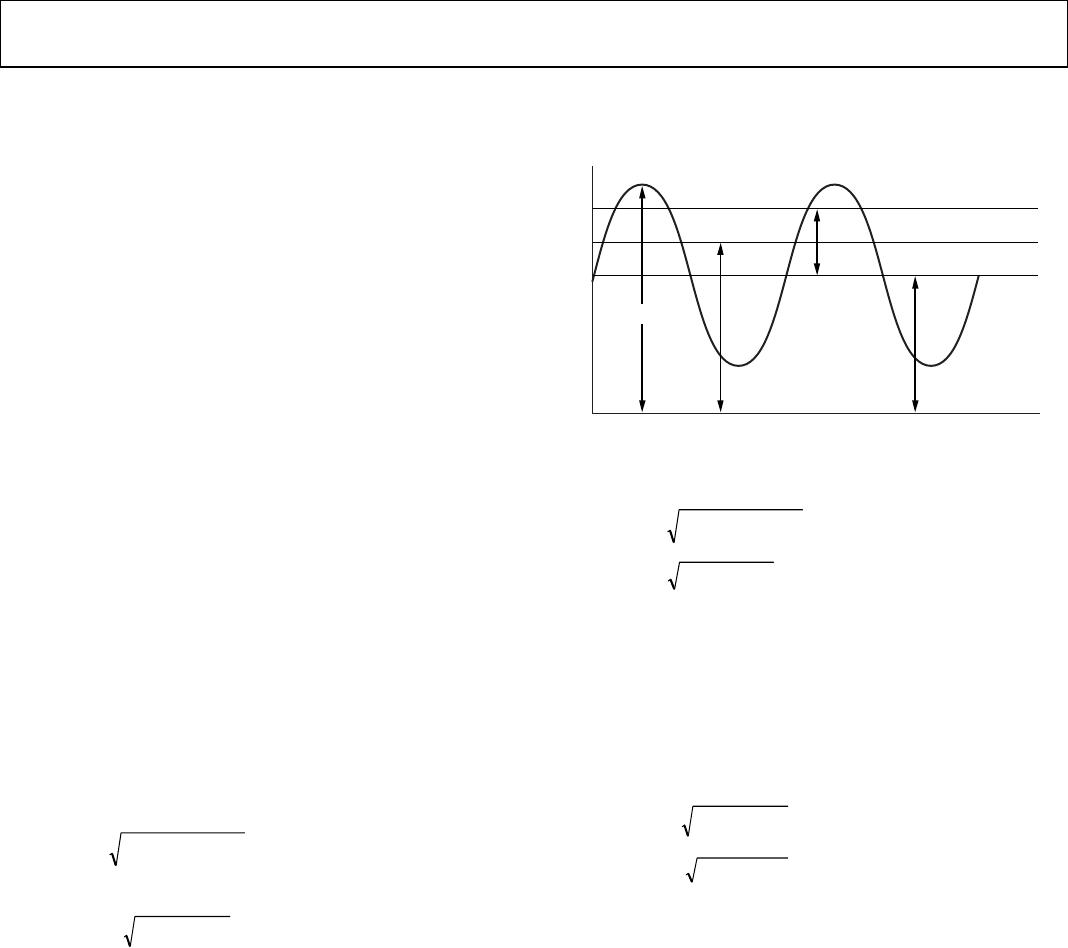

Figure 23 shows the eye diagram for the ADuM240D/ADuM240E/

ADuM241D/ADuM241E/ADuM242D/ADuM242E. The

measurement was taken using an Agilent 81110A pulse pattern

generator at 150 Mbps with pseudorandom bit sequences (PRBS)

2(n − 1), n = 14, for 5 V supplies. Jitter was measured with the

Tektronix Model 5104B oscilloscope, 1 GHz, 10 GSPS with the

DPOJET jitter and eye diagram analysis tools. The result shows a

typical measurement on the ADuM240D/ADuM240E/

ADuM241D/ADuM241E/ADuM242D/ADuM242E with

490 ps p-p jitter.

Figure 23. ADuM240D/ADuM240E/ADuM241D/ADuM241E/ADuM242D/

ADuM242E Eye Diagram

INSULATION LIFETIME

All insulation structures eventually break down when subjected

to voltage stress over a sufficiently long period. The rate of

insulation degradation is dependent on the characteristics of the

voltage waveform applied across the insulation as well as on the

materials and material interfaces.

The two types of insulation degradation of primary interest are

breakdown along surfaces exposed to the air and insulation

wear out. Surface breakdown is the phenomenon of surface

tracking, and the primary determinant of surface creepage

requirements in system level standards. Insulation wear out is the

phenomenon where charge injection or displacement currents

inside the insulation material cause long-term insulation

degradation.

Surface Tracking

Surface tracking is addressed in electrical safety standards by

setting a minimum surface creepage based on the working voltage,

the environmental conditions, and the properties of the insulation

material. Safety agencies perform characterization testing on the

surface insulation of components that allows the components to be

categorized in different material groups. Lower material group

ratings are more resistant to surface tracking and, therefore, can

provide adequate lifetime with smaller creepage. The minimum

creepage for a given working voltage and material group is in each

V

DD1

GND

1

V

IA

V

IB

V

IC

/V

OC

V

ID

/V

OD

DISABLE

1

/V

E1

/NIC

GND

1

V

DD2

GND

2

V

OA

V

OB

V

IC

/V

OC

V

ID

/V

OD

DISABLE

2

/V

E2

/NIC

GND

2

13576-010

INPUT (V

Ix

)

OUTPUT (V

Ox

)

t

PLH

t

PHL

50%

50%

13576-011

105

0

1

2

3

4

VOL

AGE (V)

5

0

TIME (ns)

–5–10

13576-012