45

COMMERCIAL AND INDUSTRIAL

TEMPERATURE RANGES

IDT72V3640/50/60/70/80/90 3.3V HIGH DENSITY SUPERSYNC II

TM

36-BIT FIFO

1,024 x 36, 2,048 x 36, 4,096 x 36, 8,192 x 36, 16,384 x 36 and 32,768 x 36

THE INSTRUCTION REGISTER

The Instruction register allows an instruction to be shifted in serially into the

processor at the rising edge of TCLK.

The Instruction is used to select the test to be performed, or the test data

register to be accessed, or both. The instruction shifted into the register is latched

at the completion of the shifting process when the TAP controller is at Update-

IR state.

The instruction register must contain 4 bit instruction register-based cells

which can hold instruction data. These mandatory cells are located nearest the

serial outputs they are the least significant bits.

TEST DATA REGISTER

The Test Data register contains three test data registers: the Bypass, the

Boundary Scan register and Device ID register.

These registers are connected in parallel between a common serial input

and a common serial data output.

The following sections provide a brief description of each element. For a

complete description, refer to the IEEE Standard Test Access Port Specification

(IEEE Std. 1149.1-1990).

TEST BYPASS REGISTER

The register is used to allow test data to flow through the device from TDI

to TDO. It contains a single stage shift register for a minimum length in serial path.

When the bypass register is selected by an instruction, the shift register stage

is set to a logic zero on the rising edge of TCLK when the TAP controller is in

the Capture-DR state.

The operation of the bypass register should not have any effect on the

operation of the device in response to the BYPASS instruction.

THE BOUNDARY-SCAN REGISTER

The Boundary Scan Register allows serial data TDI be loaded in to or read

out of the processor input/output ports. The Boundary Scan Register is a part

of the IEEE 1149.1-1990 Standard JTAG Implementation.

THE DEVICE IDENTIFICATION REGISTER

The Device Identification Register is a Read Only 32-bit register used to

specify the manufacturer, part number and version of the processor to be

determined through the TAP in response to the IDCODE instruction.

IDT JEDEC ID number is 0xB3. This translates to 0x33 when the parity

is dropped in the 11-bit Manufacturer ID field.

For the IDT72V3640/72V3650/72V3660/72V3670/72V3680/72V3690,

the Part Number field contains the following values:

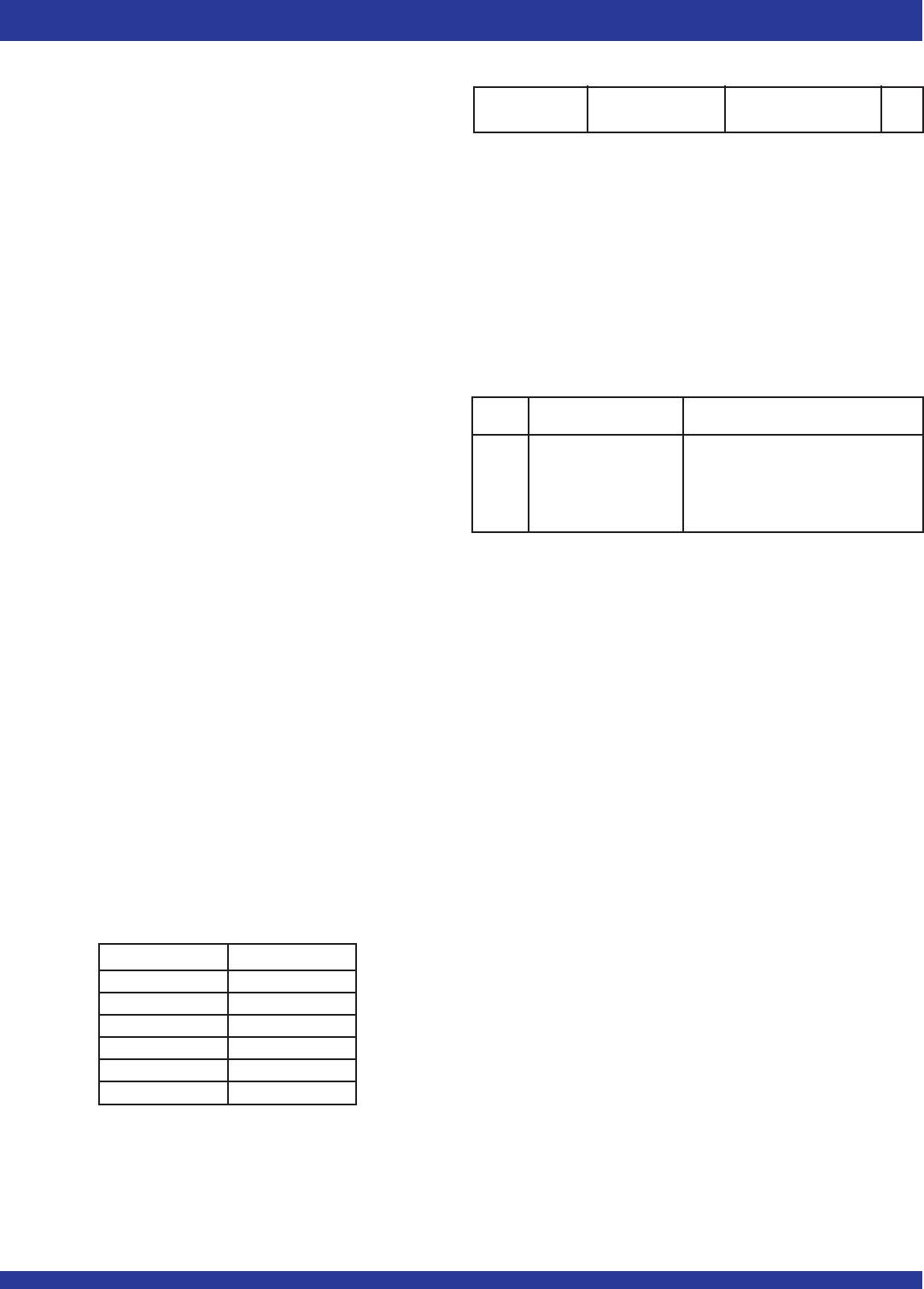

IDT72V3640/50/60/70/80/90 JTAG Device Identification Register

31(MSB) 28 27 12 11 1 0(LSB)

Version (4 bits) Part Number (16-bit) Manufacturer ID (11-bit)

0X0 0X33 1

JTAG INSTRUCTION REGISTER

The Instruction register allows instruction to be serially input into the device

when the TAP controller is in the Shift-IR state. The instruction is decoded to

perform the following:

• Select test data registers that may operate while the instruction is

current. The other test data registers should not interfere with chip

operation and the selected data register.

• Define the serial test data register path that is used to shift data between

TDI and TDO during data register scanning.

The Instruction Register is a 4 bit field (i.e.IR3, IR2, IR1, IR0) to decode 16

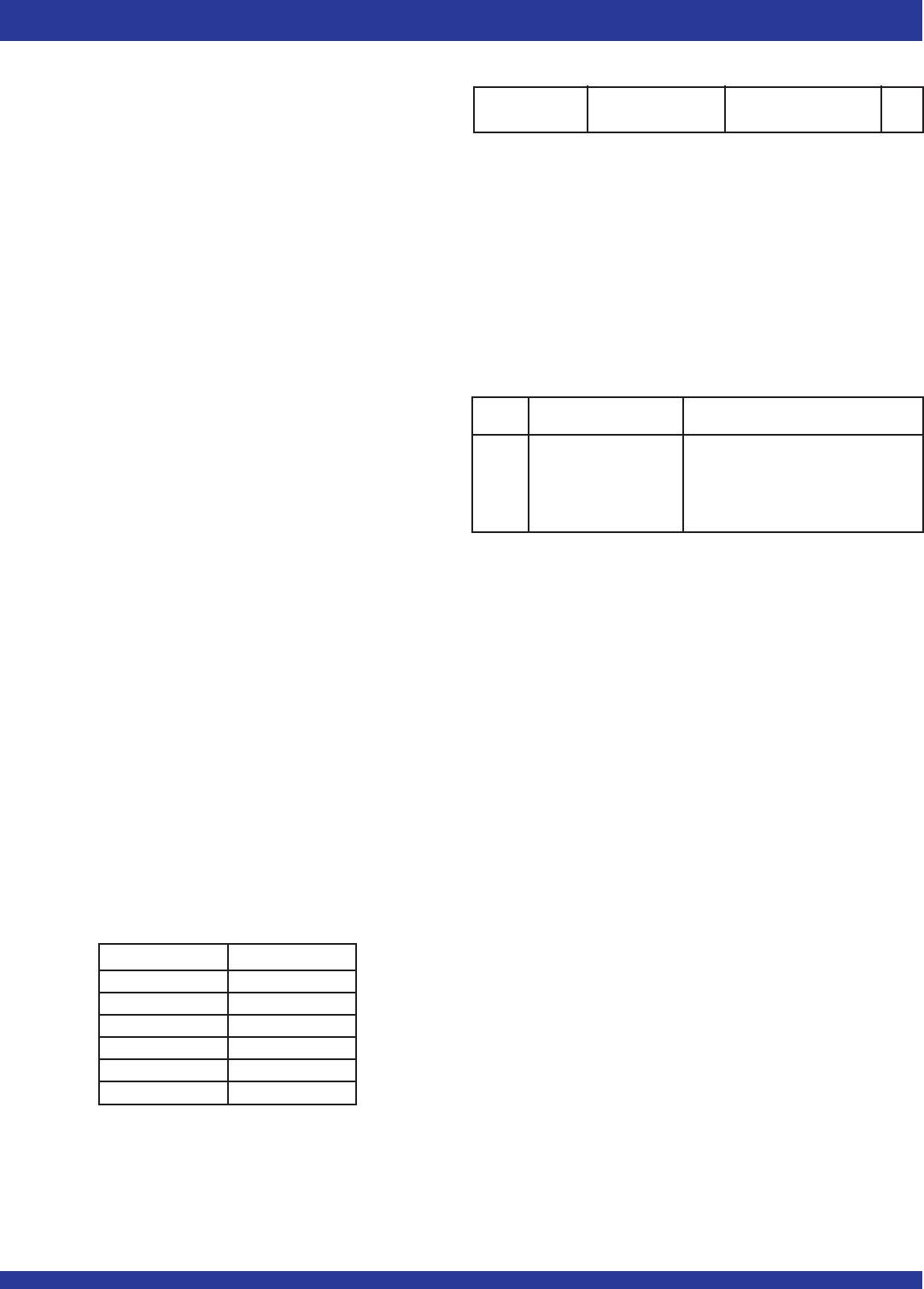

different possible instructions. Instructions are decoded as follows.

Hex Instruction Function

Value

0x00 EXTEST Select Boundary Scan Register

0x02 IDCODE Select Chip Identification data register

0x01 SAMPLE/PRELOAD Select Boundary Scan Register

0x03 HI-Z JTAG

0x0F BYPASS Select Bypass Register

Table 6. JTAG Instruction Register Decoding

The following sections provide a brief description of each instruction. For

a complete description refer to the IEEE Standard Test Access Port Specification

(IEEE Std. 1149.1-1990).

EXTEST

The mandatory EXTEST instruction is provided for external circuity and

board level interconnection check.

IDCODE

This instruction is provided to select Device Identification Register to read

out manufacture’s identity, part number and version number.

SAMPLE/PRELOAD

The mandatory SAMPLE/PRELOAD instruction allows data values to be

loaded onto the latched parallel outputs of the boundary-scan shift register prior

to selection of the boundary-scan test instruction. The SAMPLE instruction

allows a snapshot of data flowing from the system pins to the on-chip logic or vice

versa.

HIGH-Z

This instruction places all the output pins on the device into a high impedance

state.

BYPASS

The Bypass instruction contains a single shift-register stage and is set to

provide a minimum-length serial path between the TDI and the TDO pins of the

device when no test operation of the device is required.

Device Part# Field

IDT72V3640 04E5

IDT72V3650 04E4

IDT72V3660 04E3

IDT72V3670 04E2

IDT72V3680 04E1

IDT72V3690 04E0