2011-2015 Microchip Technology Inc. DS20002270E-page 9

24AA1026/24LC1026/24FC1026

6.0 WRITE OPERATIONS

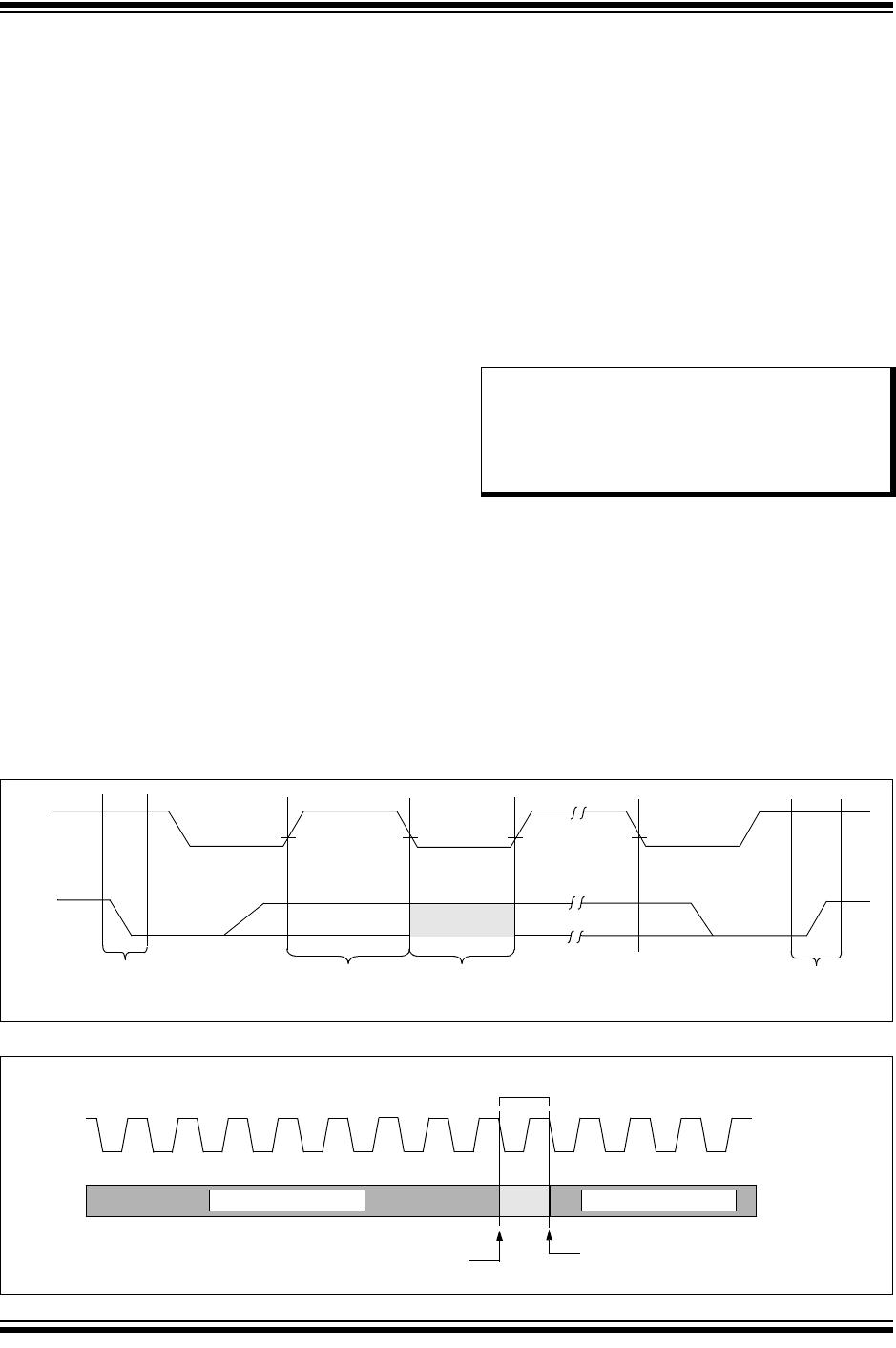

6.1 Byte Write

Following the Start condition from the master, the

control code (four bits), the Chip Select (two bits), the

block select (one bit), and the R/W bit (which is a logic

low) are clocked onto the bus by the master transmitter.

This indicates to the addressed slave receiver that the

address high byte will follow after it has generated an

Acknowledge bit during the ninth clock cycle.

Therefore, the next byte transmitted by the master is

the high-order byte of the word address and will be

written into the Address Pointer of the 24XX1026. The

next byte is the Least Significant Address Byte. After

receiving another Acknowledge signal from the

24XX1026, the master device will transmit the data

word to be written into the addressed memory location.

The 24XX1026 acknowledges again and the master

generates a Stop condition. This initiates the internal

write cycle and during this time, the 24XX1026 will not

generate Acknowledge signals as long as the control

byte being polled matches the control byte that was

used to initiate the write (Figure 6-1). If an attempt is

made to write to the array with the WP pin held high, the

device will acknowledge the command, but no write

cycle will occur, no data will be written and the device

will immediately accept a new command. After a byte

Write command, the internal address counter will point

to the address location following the one that was just

written.

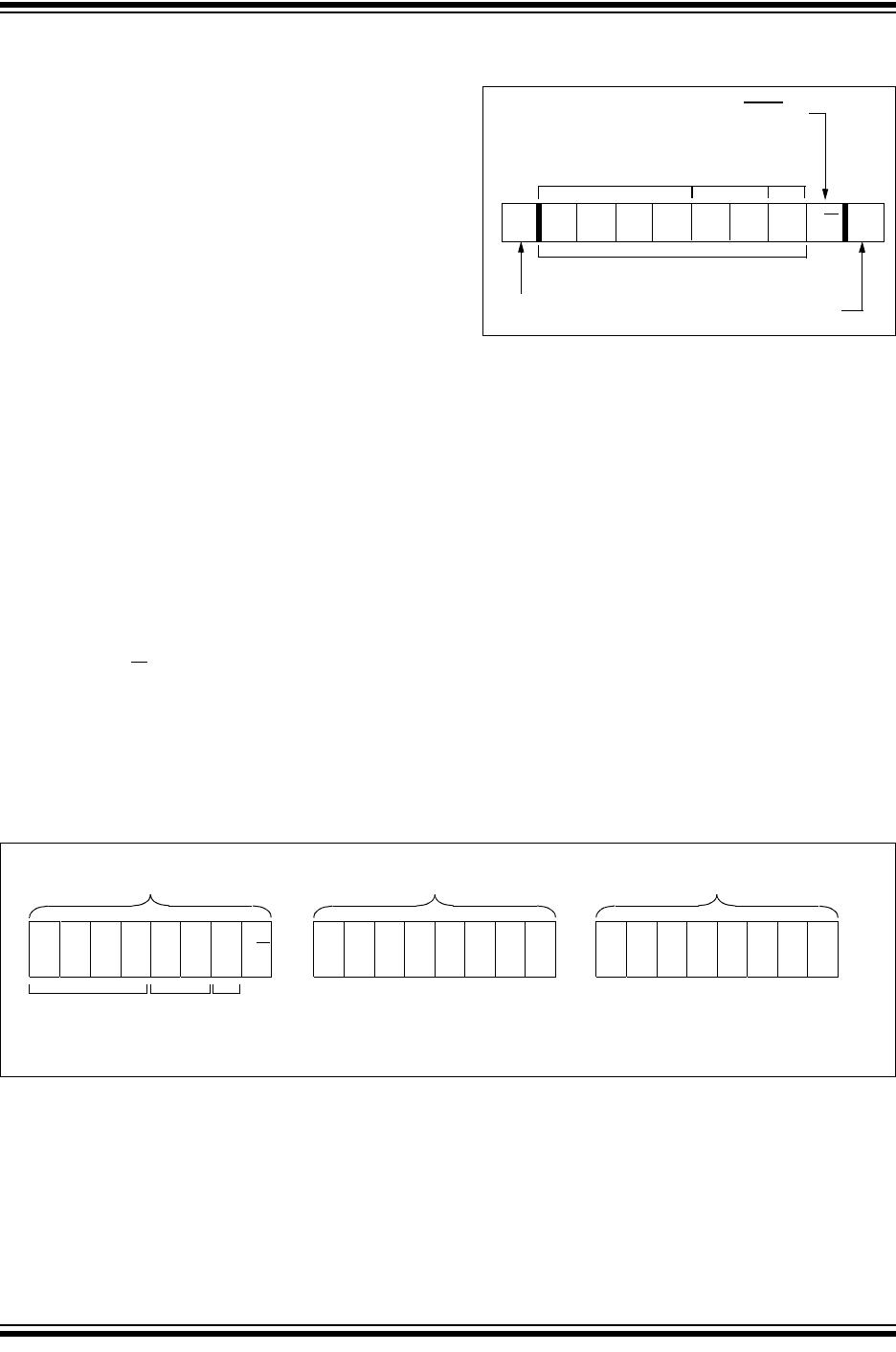

6.2 Page Write

The write control byte, word address and the first data

byte are transmitted to the 24XX1026 in the same way

as in a byte write. But instead of generating a Stop

condition, the master transmits up to 127 additional

bytes, which are temporarily stored in the on-chip page

buffer and will be written into memory after the master

has transmitted a Stop condition. After receipt of each

word, the seven lower Address Pointer bits are

internally incremented by one. If the master should

transmit more than 128 bytes prior to generating the

Stop condition, the address counter will roll over and

the previously received data will be overwritten. As with

the byte write operation, once the Stop condition is

received, an internal write cycle will begin (Figure 6-2).

If an attempt is made to write to the array with the WP

pin held high, the device will acknowledge the

command, but no write cycle will occur, no data will be

written and the device will immediately accept a new

command.

6.3 Write Protection

The WP pin allows the user to write-protect the entire

array (00000-1FFFF) when the pin is tied to V

CC. If tied

to V

SS the write protection is disabled. The WP pin is

sampled at the Stop bit for every Write command

(Figure 1-1). Toggling the WP pin after the Stop bit will

have no effect on the execution of the write cycle.

Note: When doing a write of less than 128 bytes

the data in the rest of the page is

refreshed along with the data bytes being

written. This will force the entire page to

endure a write cycle, for this reason

endurance is specified per page.

Note: Page write operations are limited to

writing bytes within a single physical page,

regardless of the number of bytes

actually being written. Physical page

boundaries start at addresses that are

integer multiples of the page buffer size

(or ‘page size’) and end at addresses that

are integer multiples of [page size – 1]. If

a Page Write command attempts to write

across a physical page boundary, the

result is that the data wraps around to the

beginning of the current page (overwriting

data previously stored there), instead of

being written to the next page as might be

expected. It is therefore necessary for the

application software to prevent page write

operations that would attempt to cross a

page boundary.