960-702-170-000 Instruction Sheet

IS-960S

NorComp, Inc. This document is subject to change Page 2 of 3

Charlotte, NC Rev 0 12-13-11 Date Printed 12/13/2011

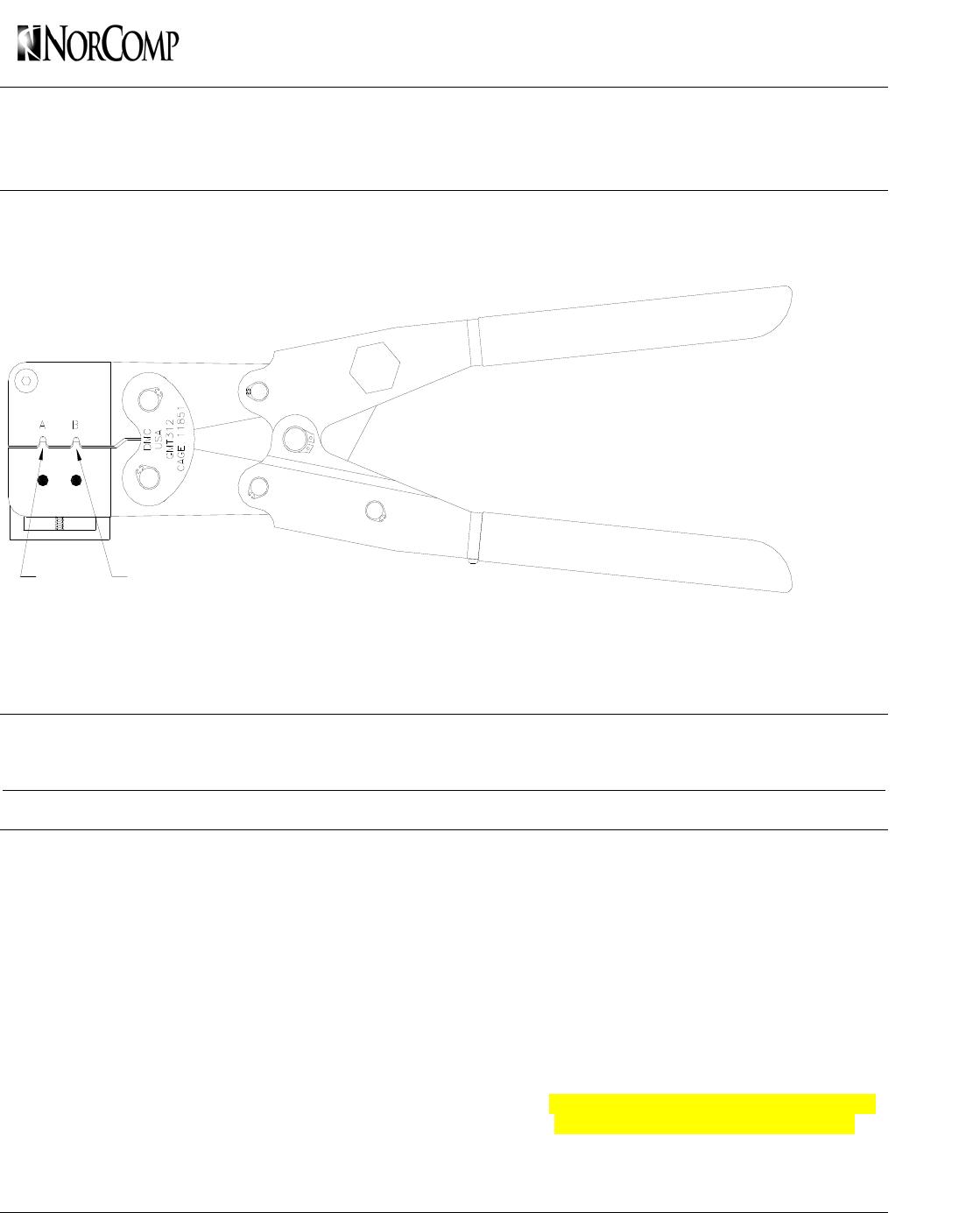

Tool

Stationary

Jaw

Wire Strip

Length

Wire & Insulation

should be visible in

Inspection Window

Figure 2

3. CRIMPING PROCEDURE

Strip the wire to the length indicated, taking care not

to nick or cut the wire strands. Select an applicable

contact and identify the appropriate crimping

chamber according to the wire size markings on the

tool.

Refer to Figure 2, and proceed as follows:

1. Hold the tool so that the front is facing you.

Squeeze tool handles together and allow

them to open fully.

2. Insert the contact (mating end first) into the

hole in the locator which corresponds with

the appropriate crimping chamber. Make

sure that the open “U” of the wire barrel and

insulation barrel face the stationary jaw.

CAUTION Make sure that both sides of the

contact insulation barrel are started

evenly into the crimping chamber.

Do NOT attempt to crimp an

improperly positioned contact.

3. Hold the contact in position, and squeeze

the tool handles together until ratchet

engages sufficiently to hold the contact in

position. Do NOT deform insulation barrel

or wire barrel.

4. Insert stripped wire into contact insulation

and wire barrels until wire and insulation are

visible in inspection window, as shown in

Figure 2.

5. Holding the wire in place, squeeze the tool

handles together until ratchet releases.

Allow tool handles to open and remove

crimped contact.

4. CRIMP PULL TEST

1. Refer to Section 3, CRIMPING

PROCEDURE, and crimp the contact

accordingly to achieve pull test in Figure 3.

WIRE SIZE TEST PULL

Max AWG lb.

30 2

28 4

26 6

Figure 3

5. CRIMP ADJUSTMENT

1. See Manufacturers data sheet supplied with

hand tool.

6. DAILY MAINTENANCE

Properly crimped terminals are controlled by the

following maintenance and inspection

procedures.

1. Clean all dust, dirt, moisture and other

foreign matter from the crimp jaws that could

damage the crimp area of the dies.

DO NOT immerse tool in cleaning solution

2. The pivot pin and ratcheted pawl-bearing

surface should be lubricated to ensure a

smooth operation.

DO NOT spray oil into tool to lubricate

3. When storing the tool, close the handles

until the ratchet pawl is about to be released

from the tooth of the ratchet. This will help

prevent the dies from being damaged.