3

3M

™

Thermally Conductive Acrylic Interface Pad 5571

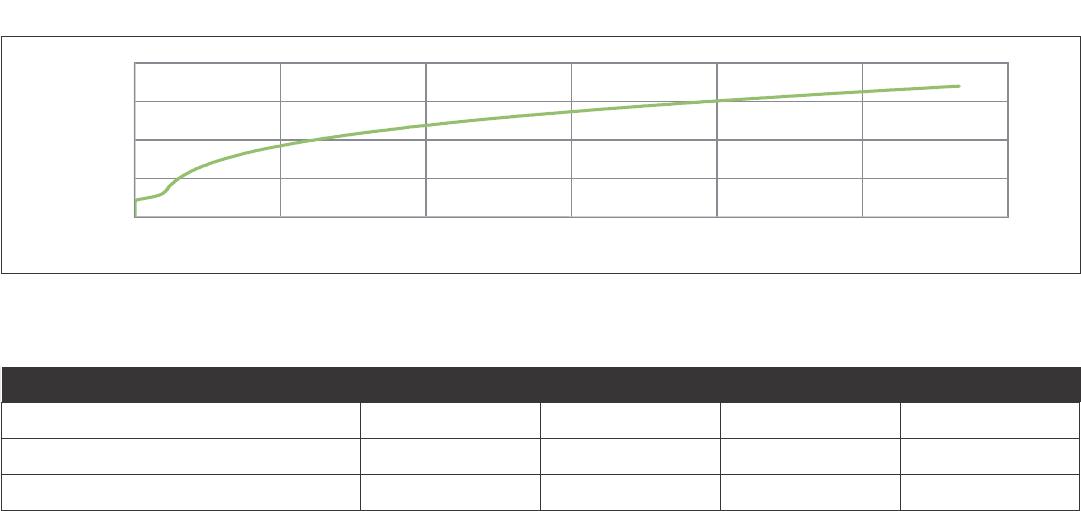

Compression vs. Stress

(2)

3M

™

Thermally Conductive Acrylic Interface Pad 5571

Application Techniques

• To obtain optimum thermal conductivity, good surfaces for wet out are required. For better contact,

clean, dry and well unied surface conditions are recommended. Typical surface cleaning solvents are

isopropyl alcohol and water (rubbing alcohol) or heptane. Note: Be sure to follow manufacturer’s safety

precautions and directions for use when using solvents.

• Ideal application temperature range is from 0°C to 40°C. Initial application to surfaces at temperatures

below 30°C is not recommended because the pad becomes too rm to be wet out readily. However,

once properly applied, low temperature holding is generally satisfactory.

Heat Resistance

*Note: The end use customer application, design & verication testing will determine the nal in use eective temperature range based

on each application’s environmental conditions.

Duration (hrs) Initial 1000 2000 5000

Thermal Conductivity (W/mK) 2.0 2.0 2.0 2.0

Hardness (Shore 00) 69 70 70 70

Appearance – No effect No effect No effect

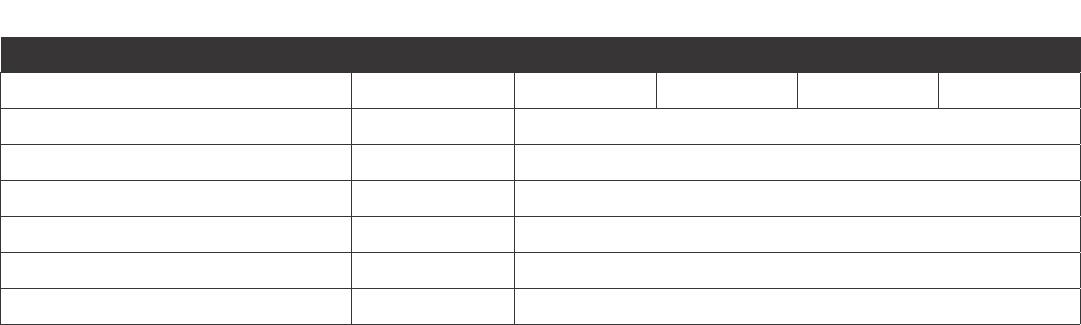

Typical Physical Properties and Performance Characteristics

Note: The following technical information and data should be considered representative or typical only and should not be used for

specication purposes. Final product specications and testing methods will be outlined in the products Certicate of Analysis

(COA) that is provided once the product is approved by 3M for general commercialization and development work is completed.

a

Methods listed as ASTM are tested in accordance with the ASTM method noted

b

Thermal Conductivity Test Methods:

• 2.0W/m-K in XY direction per Hot wire plane Test method (Test equipment: QTM-500)

• 2.0W/m-K in Z direction tested in accordance with a simplied ASTM D5470 type method (Test equipment: Tester DynTIM)

3M™ Thermally Conductive Acrylic Interface Pad 5571

Property Method

a

0.75T 1.0T 1.5T 2.0T

Thickness (mm) – 0.75 1.0 1.5 2.0

Thermal conductivity (W/mK)

b

ASTM C1113 2.0

Hardness (Shore 00) TS-KOR-217 70

Density (grams/cm

3

) TS-TM-44 1.85

Flammability UL94 V-0

Dielectric Strength (kV/mm) ASTM D149 13

Volume Resistivity (Ω-cm) JIS K6249 3.3 x 10

12

Compression vs. Stress

80

60

40

20

0

0 2 4 6 8 10 12

Stress [kg/cm

2

)

Compression [%]

• Sample size: 1.0T, 30 by 30mm

• Test speed: 0.5mm/min

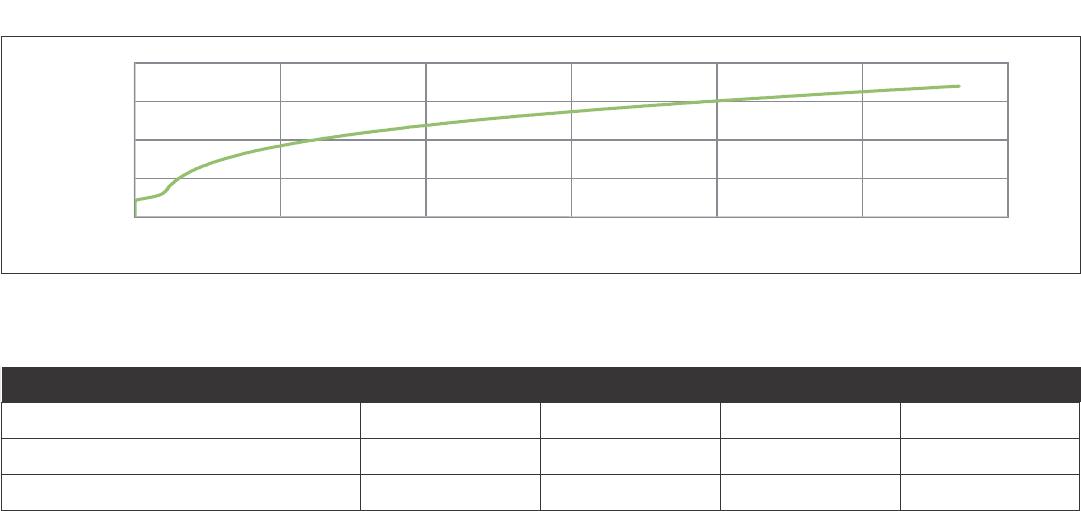

80

60

40

20

0

0 2 4 6 8 10 12

Stress [kg/cm

2

)

Sample size: 1.0T, 30 by 30mm

Test speed: 0.5mm/min

Heat Resistance

1, 2

Duration (hrs) Initial 1000 2000 5000

Thermal Conductivity (W/mK) 2.0 2.0 2.0 2.0

Hardness (Shore 00) 69 70 70 70

Appearance – No eect No eect No eect

1

Aged by dwelling at 110°C high temperature chamber.

2

The end use customer application, design and verication testing will determine the nal in-use eective temperature range based on each

application’s environmental conditions.

Certicate of Analysis (COA)

The 3M Certicate of Analysis (COA) for this product is established when the product becomes commercially available

from 3M. The Technical Data Sheet (TDS) technical information, test methods and data should be considered represen-

tative or typical only and should not be used for specication purposes. The Technical Data Sheet (TDS) information is

based on a limited set of test results and do not reect the COA specication limits. Final product specications and

associated manufacturing facility testing methods used for the commercialized product are outlined in the products

Certicate of Analysis (COA) that is provided upon request or with the products shipment.

The COA contains the 3M specications and test methods for the products performance limits that the product will be

supplied against. The 3M product is supplied to 3M COA test specications and the COA test methods. Contact your

local 3M Technical Service representative for the COA for this product.

Storage and Shelf Life

The shelf life of 3M

™

Thermally Conductive Acrylic Interface Pad 5571 is 12 months from the date of manufacture when

stored in the original packaging materials and stored at 21°C (70°F) and 50% relative humidity.