8

217 C

200 C

60 - 120 SEC.

6 C/SEC. MAX.

3 C/SEC. MAX.

(Acc. to J-STD-020C)

3 C/SEC. MAX.

150 C

255 - 260 C

100 SEC. MAX.

10 to 30 SEC.

TIME

TEMPERATURE

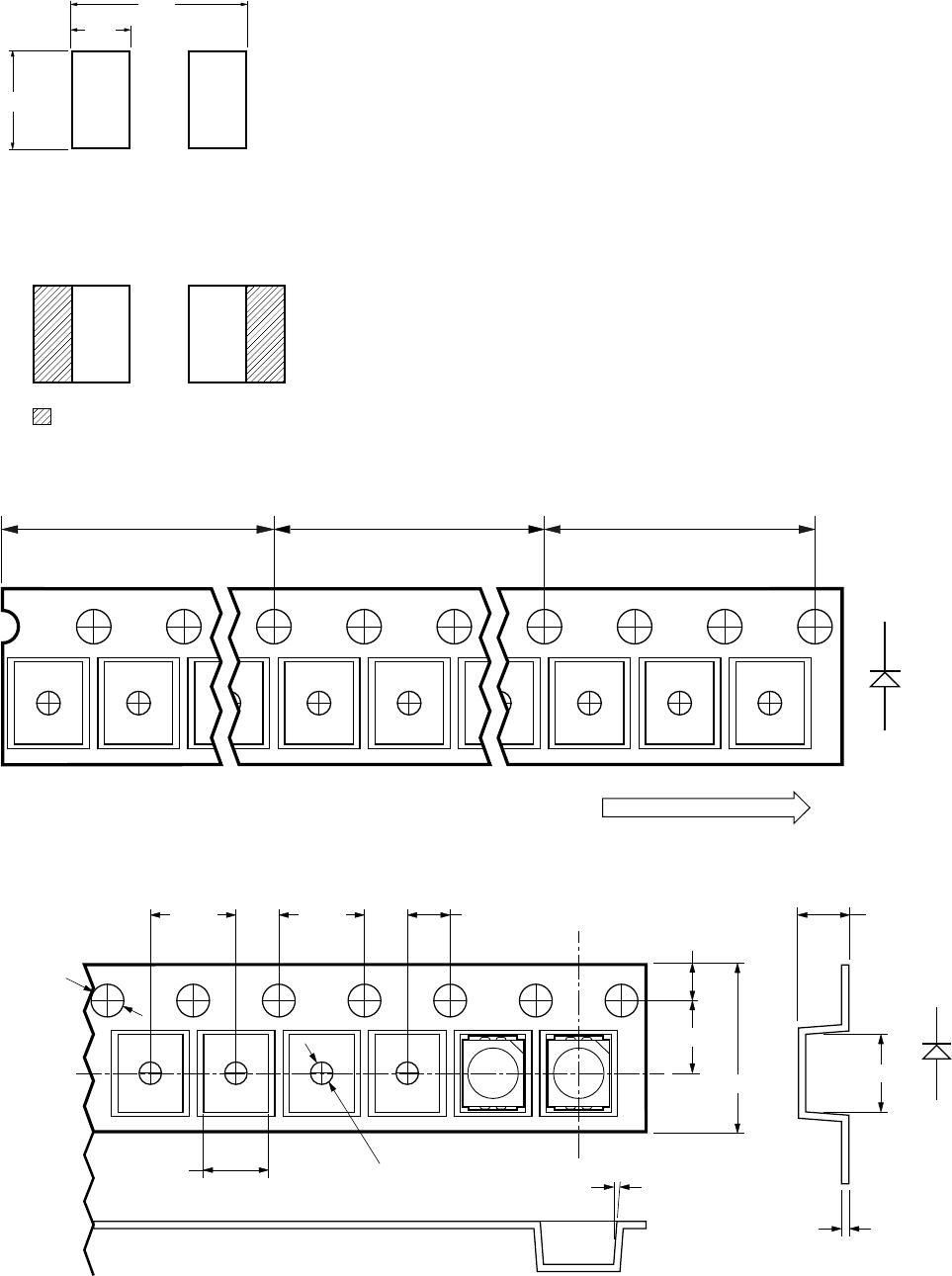

LAMINAR WAVE

BOTTOM SIDE

OF PC BOARD

HOT AIR KNIFE

TURBULENT WAVE

FLUXING

PREHEAT

0 10 20

30

50

100

150

200

250

30 40 50

TIME – SECONDS

TEMPERATURE – C

60 70 80 90 100

TOP SIDE OF

PC BOARD

CONVEYOR SPEED = 1.83 M/MIN (6 FT/MIN)

PREHEAT SETTING = 150C (100C PCB)

SOLDER WAVE TEMPERATURE = 245C

AIR KNIFE AIR TEMPERATURE = 390C

AIR KNIFE DISTANCE = 1.91 mm (0.25 IN.)

AIR KNIFE ANGLE = 40

LEADED SOLDER: SN63; FLUX: RMA

LEAD-FREE SOLDER: 96.5 wt% SN, 3 wt% Ag, 0.5 wt% Cu

NOTE: ALLOW FOR BOARDS TO BE SUFFICIENTLY COOLED

BEFORE EXERTING MECHANICAL FORCE.

Figure 7. Radiation Pattern.

Figure 9. Recommended wave soldering prole.

Figure 8. Recommended Pb-free reow soldering prole.

Note: For detail information on reow soldering of Avago surface

mount LEDs, do refer to Avago Application Note AN 1060 Surface

Mounting SMT LED Indicator Components.

Reow soldering must not be done more than 2 times. Do observe

necessary precautions of handling moisture sensitive device as stated

in below section.

0 20

CURRENT – mA

460

480

540

DOMINANT WAVELENGTH – nm

35

500

470

510

10

490

520

25

GREEN

5 15 30

530

CYAN

BLUE

DELTA V

F

(NORMALIZED AT 25°C)

-0.3

-100

TEMPERATURE – °C

0.5

0.4

0.2

0.1

0

-0.2

15050-50

0 100

-0.1

0.3

GaP/AlGaAs/

AlInGaP

InGaN/GaN

NORMALIZED INTENSITY

1.0

0

ANGULAR DISPLACEMENT – DEGREES

0.8

0.6

0.2

0.4

-70 -50

-30 0 20 30 50 70 90-90 -20-80 -60 -40 -10 10 40 60 80

Figure 6. Forward voltage shift vs. temperature.Figure 5. Dominant wavelength vs. forward current – InGaN devices.