K–7

Dimensions are shown: Inch (mm)

Specifications and dimensions subject to change

www.ck-components.com

A Series

1-4 Pole Rotary Switches

FUNCTION

AVAILABLE HARDWARE

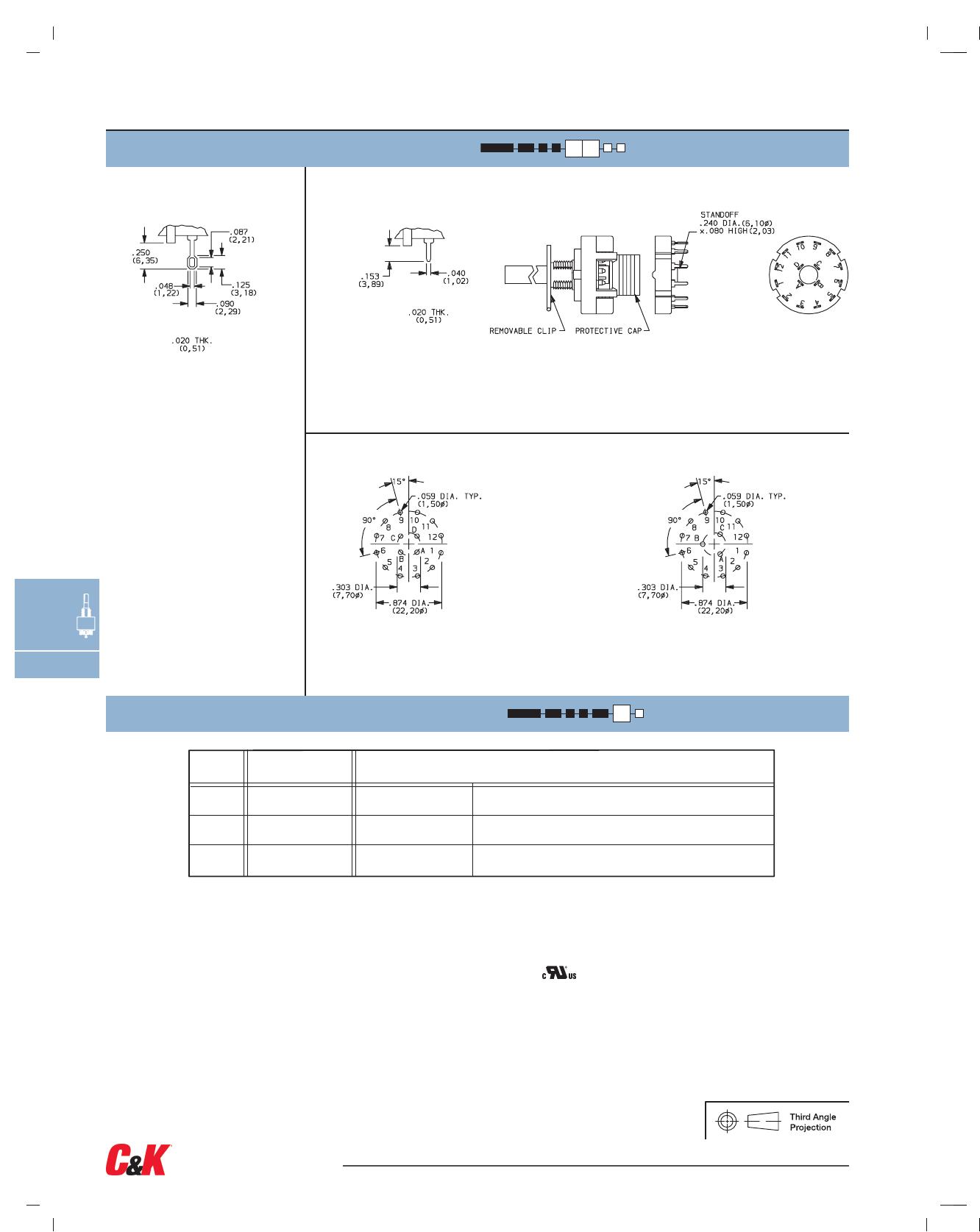

(FIG. 1)

(FIG. 2) (FIG. 3)

REMOV

ABLE CLIP

LOCATING

TA B

STANDOFF

K

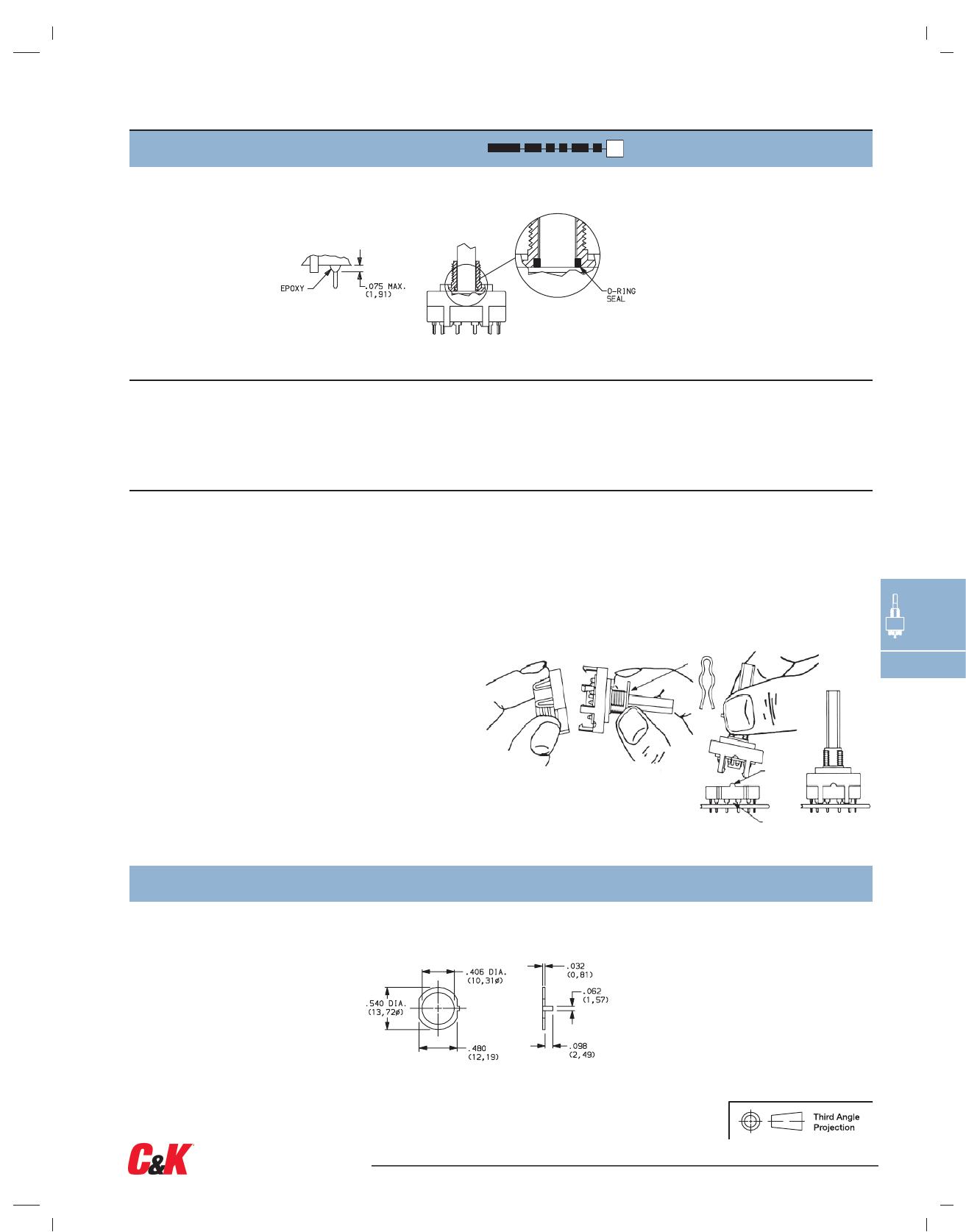

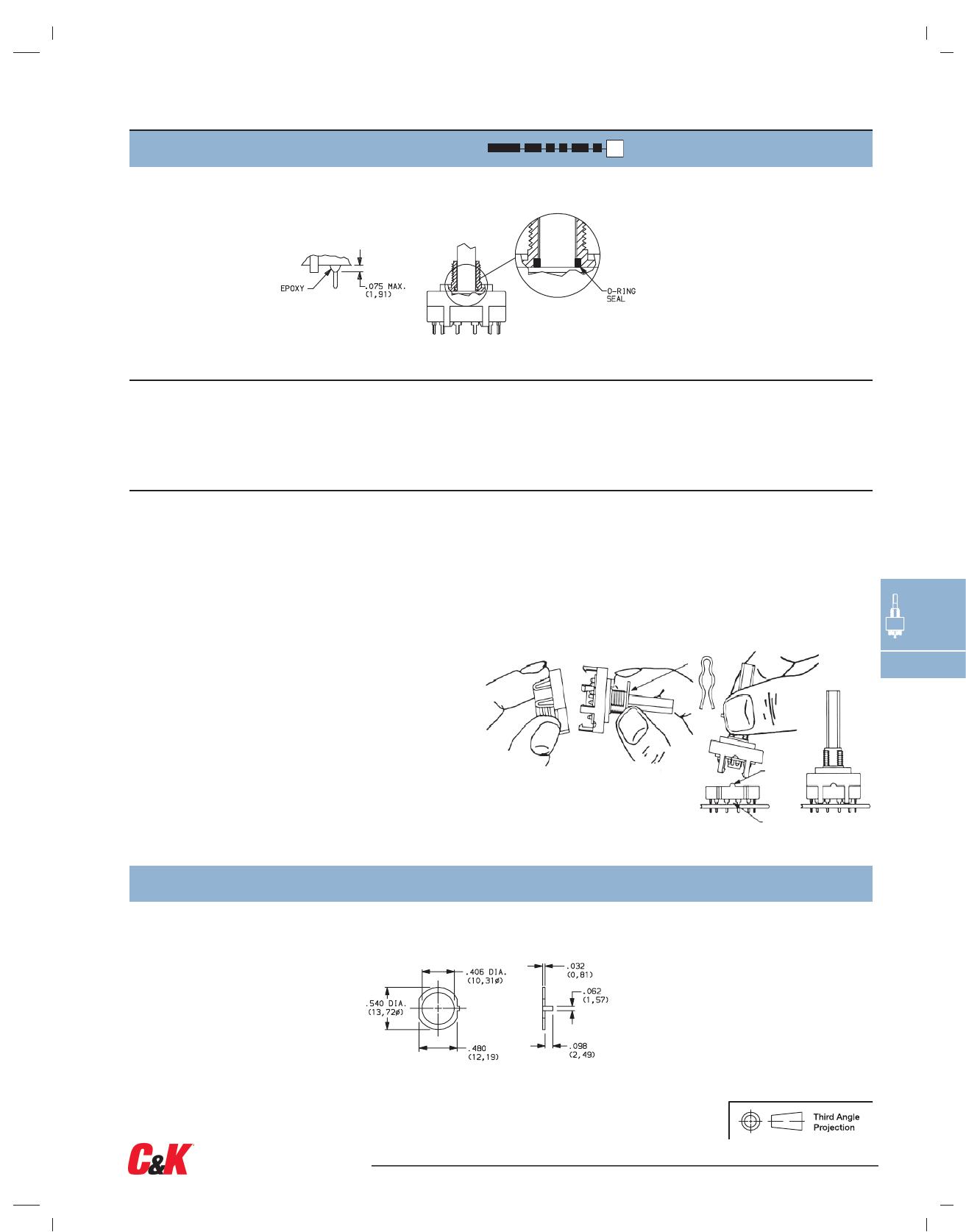

EPOXY & SPLASHPROOF BUSHING SEAL

F

SPLASHPROOF BUSHING SEAL

NONE

NO SEAL

E

EPOXY SEAL

Stop ring

P

ART NO.

767B00201

Material: Brass

Finish: Nickel plated

Setting Stops on A112 and A125 Models

The number of switch positions is adjustable on A112

and A125 models only by means of a stop ring provided

with each switch. The number of positions is pre-set on

all other models and the stop ring is factory installed.

Soldering

1. Insert switch base only into PC board.

2. Do not bend terminals.

3. Wave soldering recommended at

500F solder temperature.

4. Hand solder at 500F, 10 sec.

max./terminal.

Switch Assembly

1. Hold housing/shaft assembly by housing. Remove

protective cap by squeezing tabs and discard. (FIG. 1)

2.

Do not push on switch shaft. Detent mechanism will

come apart.

3. While holding switch housing, align locating tab on

base with notch on housing and engage 4 housing

latches in slots on base. (FIG. 2)

4. Push firmly on housing until latches snap in place.

5. Remove clip from shaft and discard. Assembly is

complete. (FIG. 3)

Cleaning

1. Flux clean using vapor degreaser and forced

rinse or triple bath method.

2. Do not allow switch base to ‘trap’ fluids.

3. Freon TMC, TF or Methylene Chloride give

excellent results.

To set stops: Turn shaft fully counter-clockwise and

insert stop ring tab in desired hole. Install lockwasher

and nut to retain stop ring for both PC and panel

mounting. Switch without stop ring has 12 positions.

Soldering, Cleaning and Assembly Instructions for ‘MC’ Termination Option