CDM Cornell Dubilier • 140 Technology Place • Liberty, SC 29657 • Phone: (864)843-2277 • Fax: (864)843-3800

Type MLS 125 °C Flatpack, Ultra Long Life, Aluminum Electrolytic

Available with High Vibration and High Reliability Options

Vibration Test Level

The specimens, while deenergized or operating under the load conditions

specied, shall be subjected to the vibration amplitude, frequency range,

and duration specied for each case size.

Amplitude

The specimens shall be subjected to a simple harmonic motion having

an amplitude of either 0.06-inch double amplitude (maximum total

excursion) or peak level specied above (XXg peak), whichever is less. The

tolerance on vibration amplitude shall be ±10 percent.

Frequency Range

The vibration frequency shall be varied logarithmically between the

approximate limits of 10 to 2,000 Hz.

Sweep Time and Duration

The entire frequency range of 10 to 2,000 Hz and return to 10 Hz shall be

traversed in 20 minutes. This cycle shall be performed 12 times in each

of three mutually perpendicular directions (total of 36 times), so that

the motion shall be applied for a total period of approximately 12 hours.

Interruptions are permitted provided the requirements for rate of change

and test duration are met.

High Reliability Test/Burn-in Established Reliability capacitors shall be subjected to a minimum of 100

percent of the dc rated voltage at 85 ºC for 48 hours minimum but not to

exceed 96 hours. During this test, capacitors shall be adequately protected

against temporary voltage surges of 10 percent or more of the test

voltage. After burn-in, the capacitors shall be returned to room ambient

conditions and the dc leakage, capacitance, and ESR shall be measured

with respect to specied limits.

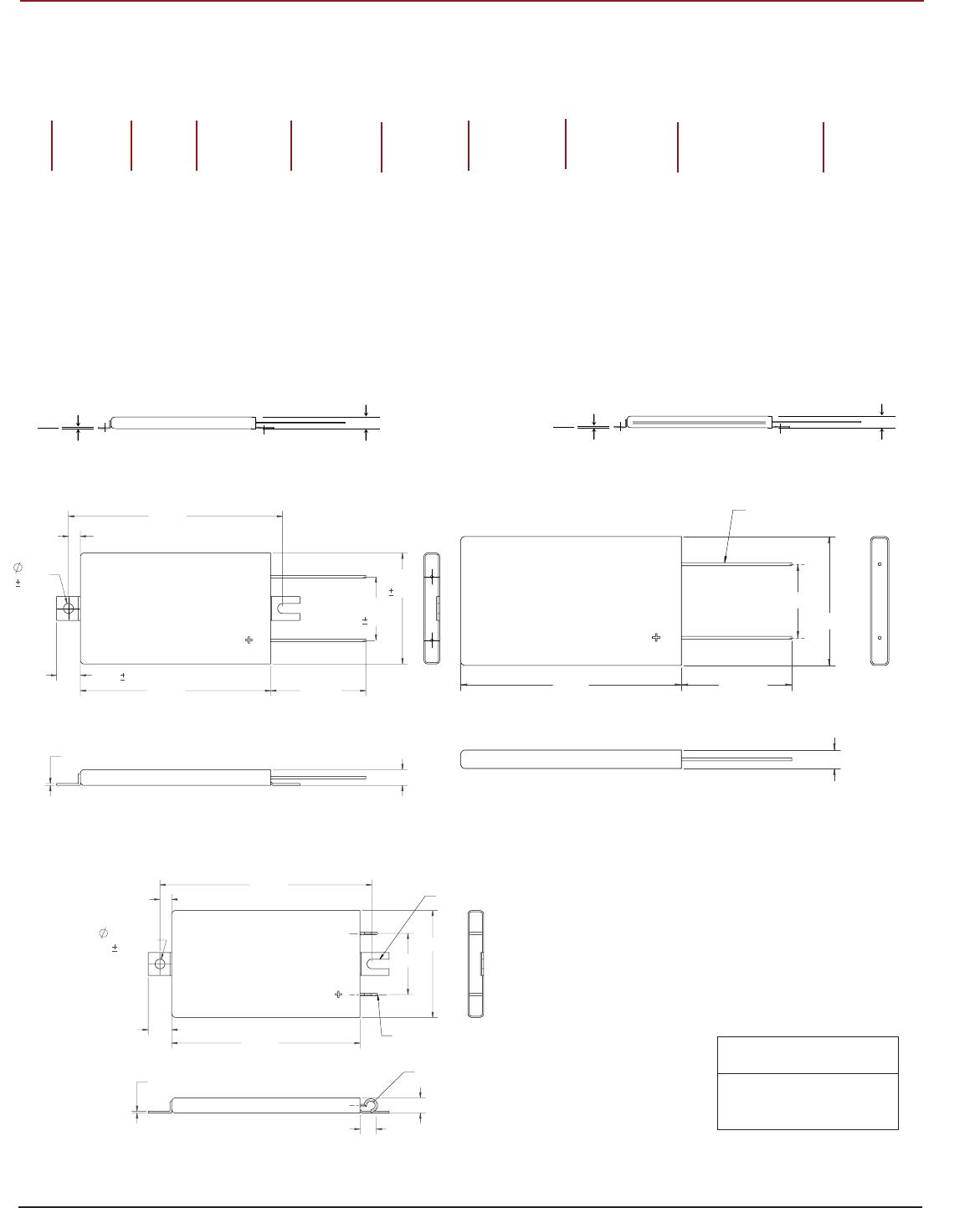

Thermal Resistance

ESL ≤30 nH measured 1/4” from case at 1 MHz

Weight Case EK 43 g typical

Case EA 76 g typical

Case EB 92 g typical

Terminals 18 AWG copper wire with 60/40 tin-lead electroplate, 20 amps max

Ripple Current Capability The ripple current capability is set by the maximum permissible internal

core temperature, 125 ºC.

Air Cooled The ripple currents in the ratings tables are for 85 ºC case temperatures.

For air temperatures without a heatsink use the multipliers Ambient

Temperature, No Heatsink.

Heatsink Cooled Temperature rise from the internal hottest spot, the core, to ambient air is

∆T = I

2

(ESR)(θcc + θca)

where θcc is the thermal resistance from core to case and θca from case to

ambient. To calculate maximum ripple capability with the MLS attached to

a heatsink use the maximum core temperature and the values for θcc.

Example As an illustration, suppose you operate an insulated MLS332M060EB1C

in 65 ºC air and attach it to a commercial heatsink with a free-air thermal

resistance of 2.7 ºC/W. Use a good thermal grease between the MLS and

the heatsink, and the total thermal resistance is 2.7 +1.8 or 4.5 ºC/W. The

power which would heat the core to 125 °C is (125 - 65)/4.5 or 13.3 W. For

an ESR of 31 mΩ, 13.3 W equates to a ripple current of 20.7 A, however, the

wire leads are rated for only 20 A.

Large Sides

Heatsinked

Case Length 1.5" 2.0" 3.0"

Insulation ºC/W ºC/W ºC/W

one

None 4.3 3.1 2.0

Polyester 4.7 3.4 2.2

both

None 2.8 2.0 1.3

Polyester 3.0 2.2 1.4