[Data Sheet]

If the product is heated during the reflow under the condition of hygroscopic state,

it may vaporize and expand which will influence the performance of the product.

Therefore, the package is waterproof. Please use the product following the conditions:

Bake the product in case of below:

①The expiration date is passed.

②The color of indicator (silica gel) turned from blue to colorless or from green to pink.

2-1.Precaution for Drive System and Off Mode

Design the circuit without the electric load exceeding the ABSOLUTE MAXIMUM RATING that

please do not apply voltage neither forward nor reverse. Especially, for the products with the

Ag-paste used in the die bonding, there’s high possibility to cause electro migration and result

The Derating Characteristics are based on the lifetime of luminous intensity and assumption

of degradation & color change of sealing resin or reflector. About its reliability,

There’s possibility for intensity of light drop according to working conditions and environments

(applied current, surrounding temperature and humidity, corrosive gases), please call our Sales

①Longtime intensity of light life

2-4.Applied Stress on Product

No resin hardening agent such as filler is used in the sealing resin of the product.

Therefore, please pay attention to the overstress on it which may influence its reliability.

The Product is LED. We are not responsible for the usage as the diode such as Protection Chip,

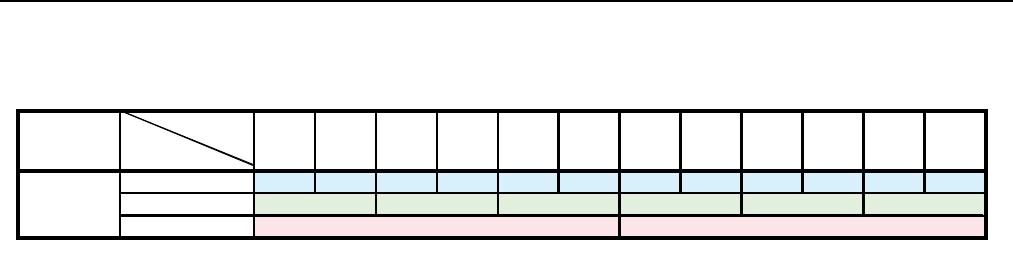

Please storing in the airtight container

②After opening

package

5〜30℃ Below 70%RH Within 168h

with our desiccant (silica gel)

(Even if the product is within the expiration date.)

Remark

so please try not to apply stress on it.

・Reel and embossed tape are easy to be deformed when baking,

Rectifier, Switching and so on.

(Deviation of VF Value will cause deviation of current in LED.) Furthermore, for off mode,

please evaluate its using conditions and environment and use it after confirmed there is no problem.

staffs for inquiries about the concerned application below.

applies on the products. If drive by constant voltage, it may cause current deviation of the LED and

result in deviation of luminous intensity, so we recommend to drive by constant current.

[SMLP36RGB series]

■Precaution (Surface Mount Device)

Temperature

①Before using 5〜30℃ 30〜70%RH

from Receiving

Storage with waterproof package

________________________________________________________

www.rohm.com

©2016 ROHM Co., Ltd. All rights reserved

6/9

2017.11 - Rev.007