10

16

14

12

10

8

6

THRESHOLD-TO-NOISE RATIO - (Vp-p/VRMS)

1E-151E-3 1E-5 1E-7 1E-9 1E-11 1E-13

BIT-ERROR RATIO - (BER)

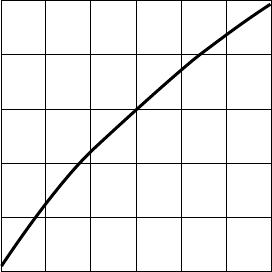

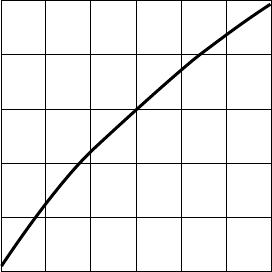

Figure 8. Receiver Threshold-to-Noise Ratio vs. Probability of Error

(aka BER)

Error Rates and Noise Immunity

The probability that a fiberoptic link will make an error

is related to the receiver’s own internal random noise

and its ability to reject noise originating from the sys-

tem in which it is installed. The total noise present in

any fiberoptic receiver is normally the sum of the PIN

diode preamplifier’s noise and the host system’s elec-

trical noise. The amount of hysteresis applied to the

comparator determines the minimum signal amplitude

(also known as minimum signal threshold level) at

which the receiver can reliably detect data. The ratio

between the comparator’s switching threshold (also

known as hysteresis) and the receiver’s noise also has a

dramatic impact on probability of error. Small increases

in the comparator’s threshold-to-noise ratio result in a

very sharp reduction in the probability of error. Figure 8

shows that the receiver’s probability of error is reduced

by six orders of magnitude from (1x10-9 to 1x10-15)

when the receiver’s threshold-tonoise ratio improves

from 12:1 to 15.8:1. At any fixed temperature the total

value of the receiver’s random noise plus the host sys-

tem’s noise can be assumed to be a constant. So the

most obvious way to reduce the probability of error is

to increase the comparator’s hysteresis and increase the

amplitude of the optical signal applied to the receiver. A

less obvious but better technique for lowering the error

rate is to improve the receiver’s ability to reject electrical

noise from the system in which it resides. The fiberoptic

receivers recommended in this application note have

sufficient noise immunity to be used in most systems

without electrostatic shielding. The Avago Technologies

PIN diode pre-amps, which are used in the receiver’s

first stage, are small hybrid circuits, and these small

hybrid components do not function as particularly

effective antennas. For extremely noisy applications,

Avago Technologies offers PIN diode pre-amps in elec-

trically conductive plastic or all metal packages. Avago

Technologies manufactures a wide range of conductive

and non-conductive fiberoptic components that mate

with various industry-standard fiberoptic connectors.

However, the overwhelming majority of the fiberoptic

applications successfully implemented with Avago

Technologies’ fiberoptic components have not required

conductive plastic or metal receiver housings. The most

insidious and the most overlooked source of noise is

usually the host system’s +5 V power supply. The host

system’s +5 volt supply normally powers the fiberoptic

receiver, the fiberoptic transmitter and an entire system

comprised of relatively noisy digital circuits. The simple

and inexpensive power supply filters recommended

in this publication have been proven to work in a wide

range of system applications. The power-supply filters

recommended in this application note are normally suf-

ficient to protect the fiberoptic receiver from very noisy

host systems, but in extremely noisy applications addi-

tional power supply filtering could be needed.

Parts List

The TTL-compatible fiberoptic transceivers recommend-

ed in this publication are very simple and inexpensive,

so only a few external components are needed. Com-

plete parts lists for the circuits recommended in this ap-

plication note are provided in Table 5 and Table 6. The

parts listed in Table 5 are for the transmitter in Figure

3 and the receiver in Figure 4. The parts listed in Table

6 are for the transmitter in Figure 3 and the receiver in

Figure 5. All of the components described in the part

lists are compatible with the printed circuit artworks

shown in Figure 6 and Figure 7, thus minimizing the

design time and resources needed to use the low cost

fiberoptic transceivers shown in the application note.