Spec.No.JENF243A-0020AA-01 P5/9

MURATA MFG.CO.,LTD.

Reference

Only

8-3.Taping Condition

(1)Standard quantity per reel

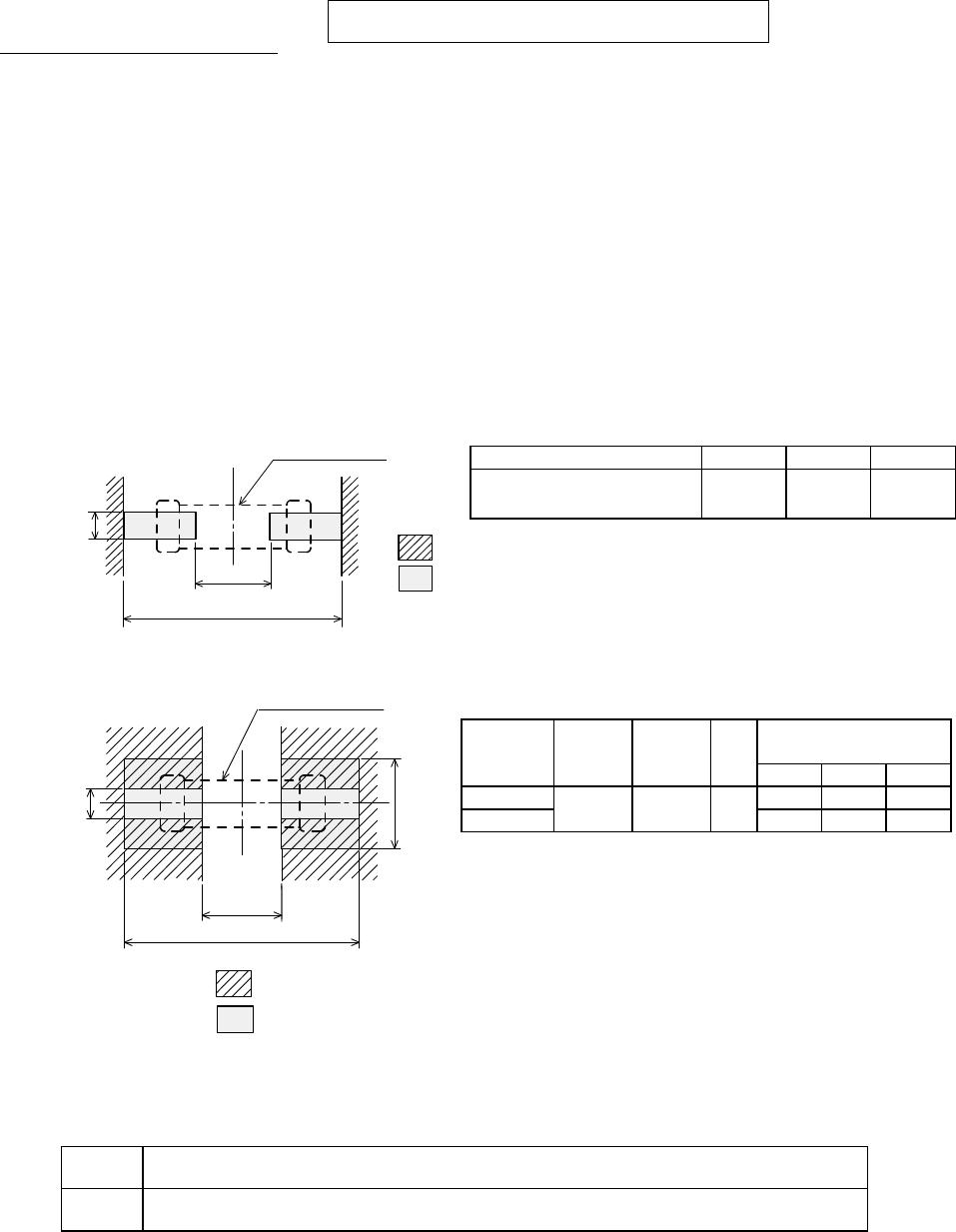

Quantity per 180mm reel 15000 pcs. / reel

(2)There shall be leader-tape(top tape and empty tape) and trailer- tape(empty tape) as follows.

(3)On paper tape, the top tape and the base tape shall not be adhered at the tip of the empty leader tape

for more than 5 pitch.

(4) Marking for reel

The following items shall be marked on a label and the label is stuck on the reel.

(Customer part number, MURATA part number, Inspection number(1), RoHS marking(2), Quantity, etc)

1) « Expression of Inspection No. » □□

OOOO

(1) (2) (3)

(1)

Factory Code

(2) Date First digit : Year / Last digit of year

Second digit : Month / Jan. to Sep. 1 to 9, Oct. to Dec. O,N,D

Third, Fourth digit : Day

(3) Serial No.

2) « Expression of RoHS marking » ROHS – Y

(△)

(1) (2)

(1)

RoHS regulation conformity parts.

(2) MURATA classification number

(5) Outside package

These reels shall be packed in the corrugated cardboard package and the following items shall be marked on

a label and the label is stuck on the box.

(Customer name, Purchasing Order Number, Customer Part Number, MURATA part number,

RoHS marking(2) , Quantity , etc)

(6)Dimensions of reel and taping(leader-tape, trailer-tape)

(in mm)

8-4. Specification of Outer Case

Outer Case Dimensions

(mm)

Standard Reel Quantity in Outer Case

(Reel)

W D H

186 186 93 5

Above Outer Case size is typical. It depends on a quantity of an order.

9. ! Caution

9-1.Surge current

Excessive surge current (pulse current or rush current) than specified rated current applied to the product may cause a

critical failure, such as an open circuit, burnout caused by excessive temperature rise.

Please contact us in advance in case of applying the surge current.

Empty tape

190 min.

Leader

Trailer

Cover tape

2.0±0.5

13.0±0.2

21.0±0.8

180±

60±

9±

13±1.4

1

0

0

3

Direction of feed

210 min.

160 min.

1

0

Label

W

D

Label

H