Spec. No. JENF243A-0005X-01 P.9/10

MURATA MFG.CO., LTD.

Reference

Only

10-5. Attention regarding P.C.B. bending

The following shall be considered when designing and laying out P.C.B.'s.

(1) P.C.B. shall be designed so that products are not subjected to the mechanical stress for board warpage.

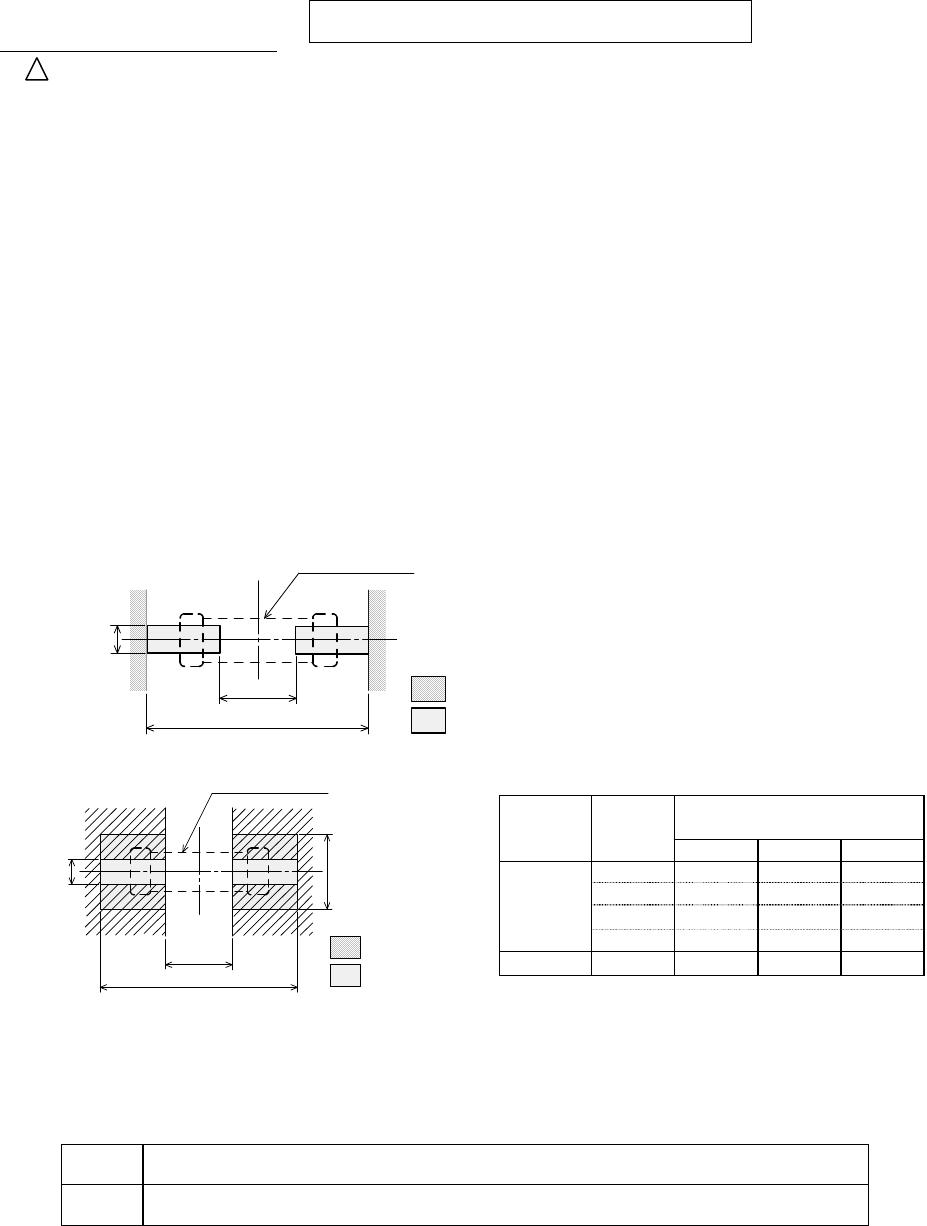

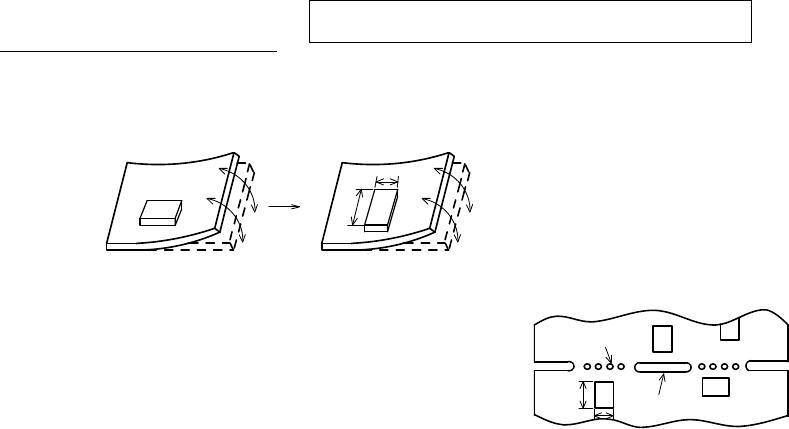

<Products direction>

Products shall be located in the sideways

direction (Length:ab) to the mechanical

stress.

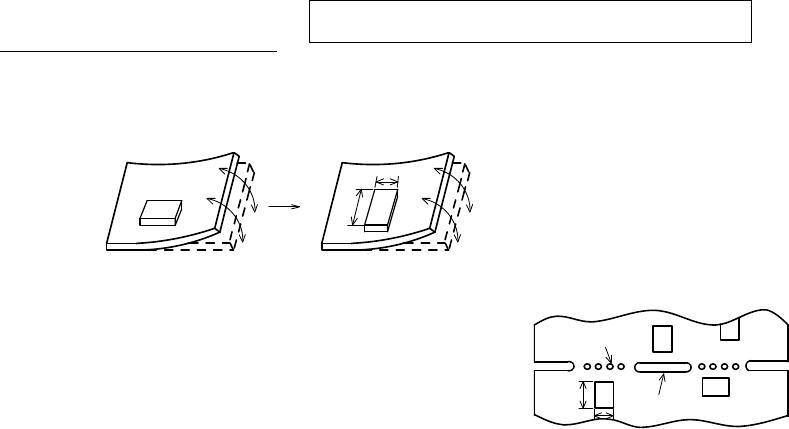

(2) Products location on P.C.B. separation.

Products (A, B, C, D) shall be located carefully

so that products are not subject to the

mechanical stress due to warping the board.

Because they may be subjected the mechanical

stress in order of A

CB D.

10-6. Mounting density

Add special attention to radiating heat of products when mounting the inductor near the products with heating.

The excessive heat by other products may cause deterioration at joint of this product with substrate.

10-7. Operating Environment

Do not use this product under the following environmental conditions, on deterioration of the Insulation

Resistance of the Ferrite material and/or corrosion of Inner Electrode may result from the use.

(1) in the corrodible atmosphere (acidic gases, alkaline gases, chlorine, sulfur gases, organic gases and etc.)

(2) in the atmosphere where liquid such as organic solvent, may splash on the products.

(3) in the atmosphere where the temperature / humidity changes rapidly and it is easy to dew.

10-8. Resin coating

The impedance value may change and/or it may affect on the product's performance due to high cure-stress of resin

to be used for coating / molding products. So please pay your careful attention when you select resin. In prior to use,

please make the reliability evaluation with the product mounted in your application set.

10-9. Cleaning Conditions

Products shall be cleaned on the following conditions.

(1) Cleaning temperature shall be limited to 60°C max. (40°C max. for IPA.)

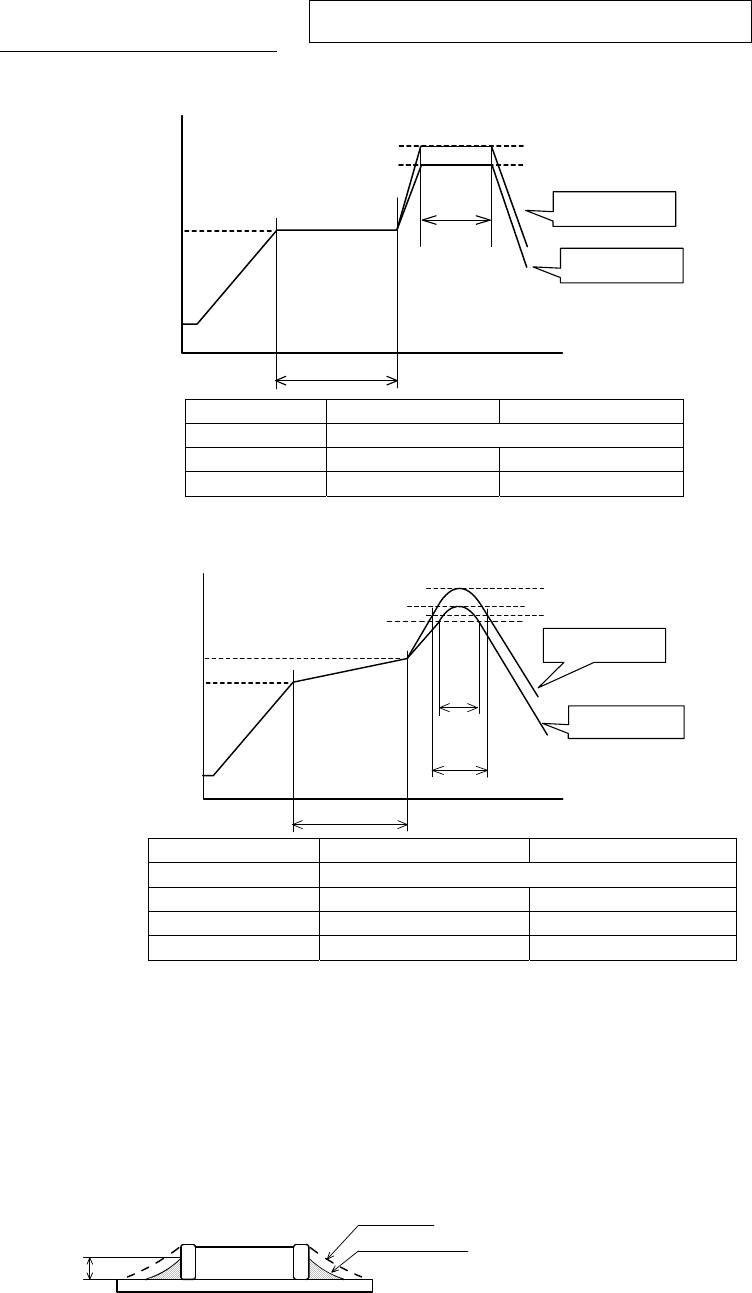

(2) Ultrasonic cleaning shall comply with the following conditions, avoiding the resonance phenomenon

at the mounted products and P.C.B.

Power:20W/ max. Frequency:28kHz to 40kHz Time:5 min max.

(3) Cleaner

1.Alternative cleaner

Isopropyl alcohol (IPA)

2.Aqueous agent

PINE ALPHA ST-100S

(4) There shall be no residual flux and residual cleaner after cleaning.

In the case of using aqueous agent, products shall be dried completely after rinse with de-ionized water

in order to remove the cleaner.

(5) Other cleaning

Please contact us.

〈

Poor example

〉

〈

Good example

〉

b

a

Seam

Slit

A

D

B

C

b

a

Length:a

b

Total page