Cautions and warnings

General

EPCOS thermistors are designed for specific applications and should not be used for purposes

not identified in our specifications, application notes and data books unless otherwise agreed

with EPCOS during the design-in-phase.

Ensure suitability of thermistor through reliability testing during the design-in phase. The ther-

mistors should be evaluated taking into consideration worst-case conditions.

Storage

Store thermistors only in original packaging. Do not open the package before storage.

Storage conditions in original packaging: storage temperature 25 °C ... +45 °C, relative hu-

midity ≤75% annual mean, maximum 95%, dew precipitation is inadmissible.

Avoid contamination of thermistors surface during storage, handling and processing.

Avoid storage of thermistor in harmful environment with effect on function on long-term opera-

tion (examples given under operation precautions).

Use thermistor within the following period after delivery:

Through-hole devices (housed and leaded PTCs): 24 months

Motor protection sensors, glass-encapsulated sensors and probe assemblies: 24 months

Telecom pair and quattro protectors (TPP, TQP): 24 months

Leadless PTC thermistors for pressure contacting: 12 months

Leadless PTC thermistors for soldering: 6 months

SMDs in EIA sizes 3225 and 4032, and for PTCs with metal tags: 24 months

SMDs in EIA sizes 0402, 0603, 0805 and 1210: 12 months

Handling

PTCs must not be dropped. Chip-offs must not be caused during handling of PTCs.

Components must not be touched with bare hands. Gloves are recommended.

Avoid contamination of thermistor surface during handling.

Soldering (where applicable)

Use rosin-type flux or non-activated flux.

Insufficient preheating may cause ceramic cracks.

Rapid cooling by dipping in solvent is not recommended.

Complete removal of flux is recommended.

Standard PTC heaters are not suitable for soldering.

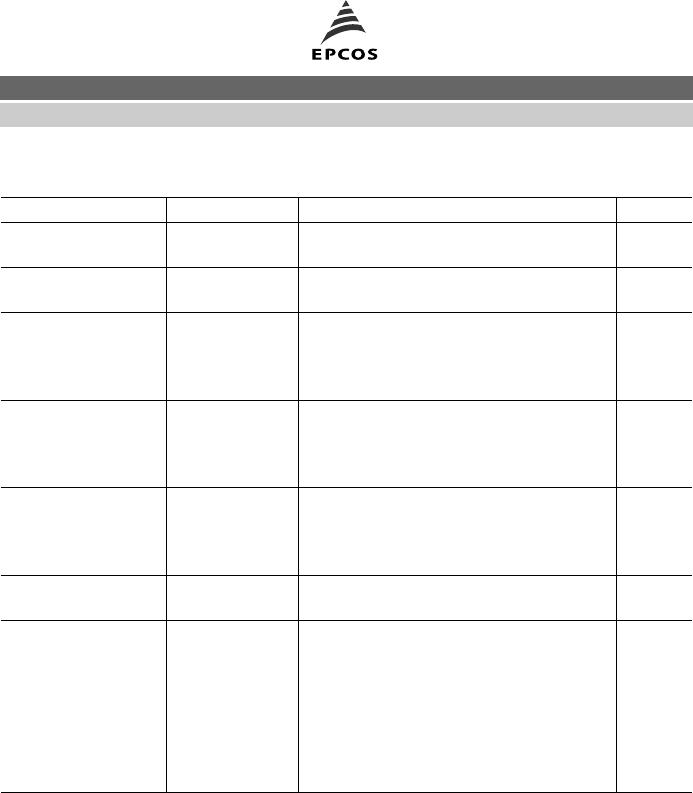

Overcurrent protection for telecom

Leaded disks

Page 9 of 13Please read Cautions and warnings and

Important notes at the end of this document.