Accu-P

®

Environmental / Mechanical Characteristics

QUALITY & RELIABILITY

Accu-P

®

is based on well established thin-film technology

and materials.

• ON-LINE PROCESS CONTROL

This program forms an integral part of the production cycle

and acts as a feedback system to regulate and control

production processes. The test procedures, which are

integrated into the production process, were developed

after long research work and are based on the highly

developed semiconductor industry test procedures and

equipment. These measures help AVX to produce a con-

sistent and high yield line of products.

• FINAL QUALITY INSPECTION

Finished parts are tested for standard electrical parameters

and visual/mechanical characteristics. Each production lot

is 100% evaluated for: capacitance and proof voltage at

2.5 U

R

. In addition, production is periodically evaluated for:

Average capacitance with histogram printout for

capacitance distribution;

IR and Breakdown Voltage distribution;

Temperature Coefficient;

Solderability;

Dimensional, mechanical and temperature stability.

QUALITY ASSURANCE

The reliability of these thin-film chip capacitors has been

studied intensively for several years. Various measures

have been taken to obtain the high reliability required today

by the industry. Quality assurance policy is based on well

established international industry standards. The reliability

of the capacitors is determined by accelerated testing

under the following conditions:

Life (Endurance) 125°C, 2U

R

, 1000 hours

Accelerated Damp

Heat Steady State 85°C, 85% RH, U

R

,

1000 hours.

TEST CONDITIONS REQUIREMENT

Life (Endurance)

125°C, 2U

R

,1000 hours No visible damage

MIL-STD-202F Method 108A

Δ C/C ≤ 2% for C≥5pF

Δ C ≤ 0.25pF for C<5pF

Accelerated Damp

85°C, 85% RH, U

R

, 1000 hours No visible damage

Heat Steady State

Δ C/C ≤ 2% for C≥5pF

MIL-STD-202F Method 103B

Δ C ≤ 0.25pF for C<5pF

Temperature Cycling

-55°C to +125°C, 15 cycles – Accu-P

®

No visible damage

MIL-STD-202F Method 107E

Δ C/C ≤ 2% for C≥5pF

MIL-STD-883D Method 1010.7

Δ C ≤ 0.25pF for C<5pF

Resistance to Solder Heat

260°C ± 5°C for 10 secs C remains within initial limits

IEC-68-2-58

ENVIRONMENTAL CHARACTERISTICS

TEST CONDITIONS REQUIREMENT

Solderability

Components completely immersed in a Terminations to be well tinned, minimum 95%

IEC-68-2-58

solder bath at 235°C for 2 secs. coverage

Leach Resistance

Components completely immersed in a

Dissolution of termination faces ≤15% of area

IEC-68-2-58

solder bath at 260±5°C for 60 secs.

Dissolution of termination edges ≤25% of length

Adhesion

A force of 5N applied for 10 secs. No visible damage

MIL-STD-202F Method 211A

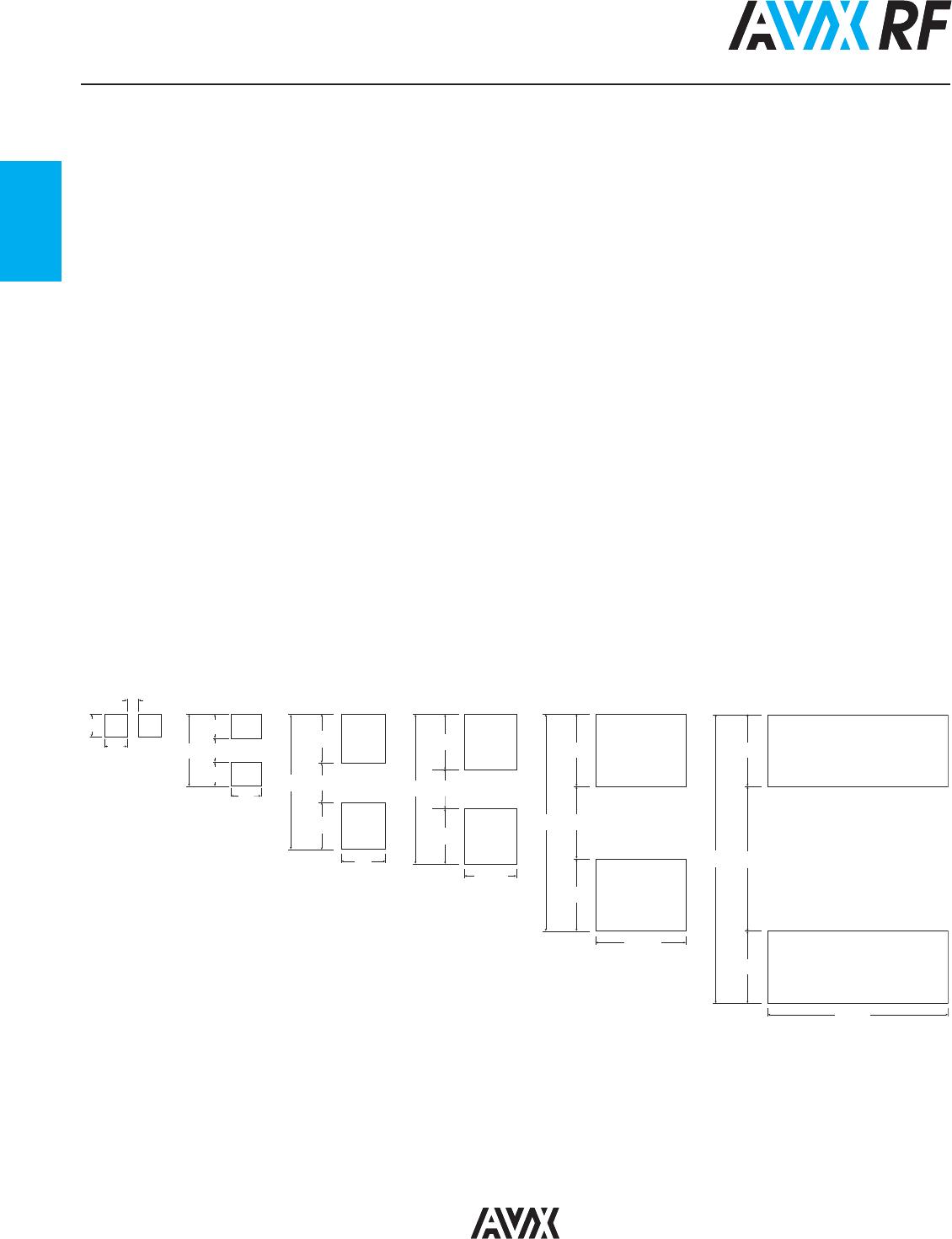

Termination Bond Strength

Tested as shown in diagram No visible damage

IEC-68-2-21 Amend. 2

Δ C/C ≤ 2% for C≥5pF

Δ C ≤ 0.25pF for C<5pF

Robustness of Termination

A force of 5N applied for 10 secs. No visible damage

IEC-68-2-21 Amend. 2

High Frequency Vibration

55Hz to 2000Hz, 20G No visible damage

MIL-STD-202F Method 201A,

204D

(Accu-P

®

only)

Storage

12 months minimum with components Good solderability

stored in “as received” packaging

MECHANICAL CHARACTERISTICS

D

45mm 45mm

D = 3mm Accu-P

D = 1mm Accu-F

1

26