DCMC 472 U 400 DC 2 B S

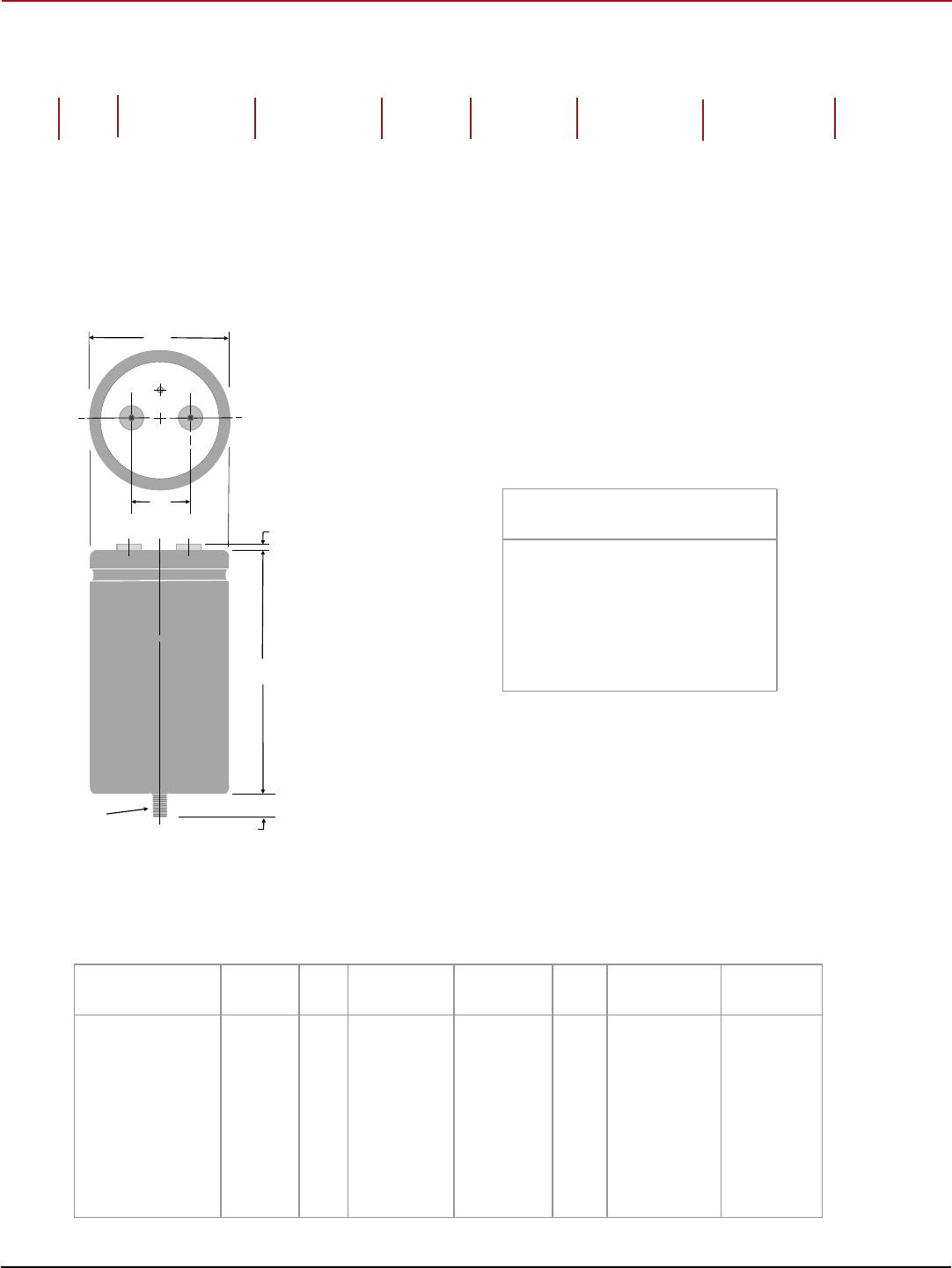

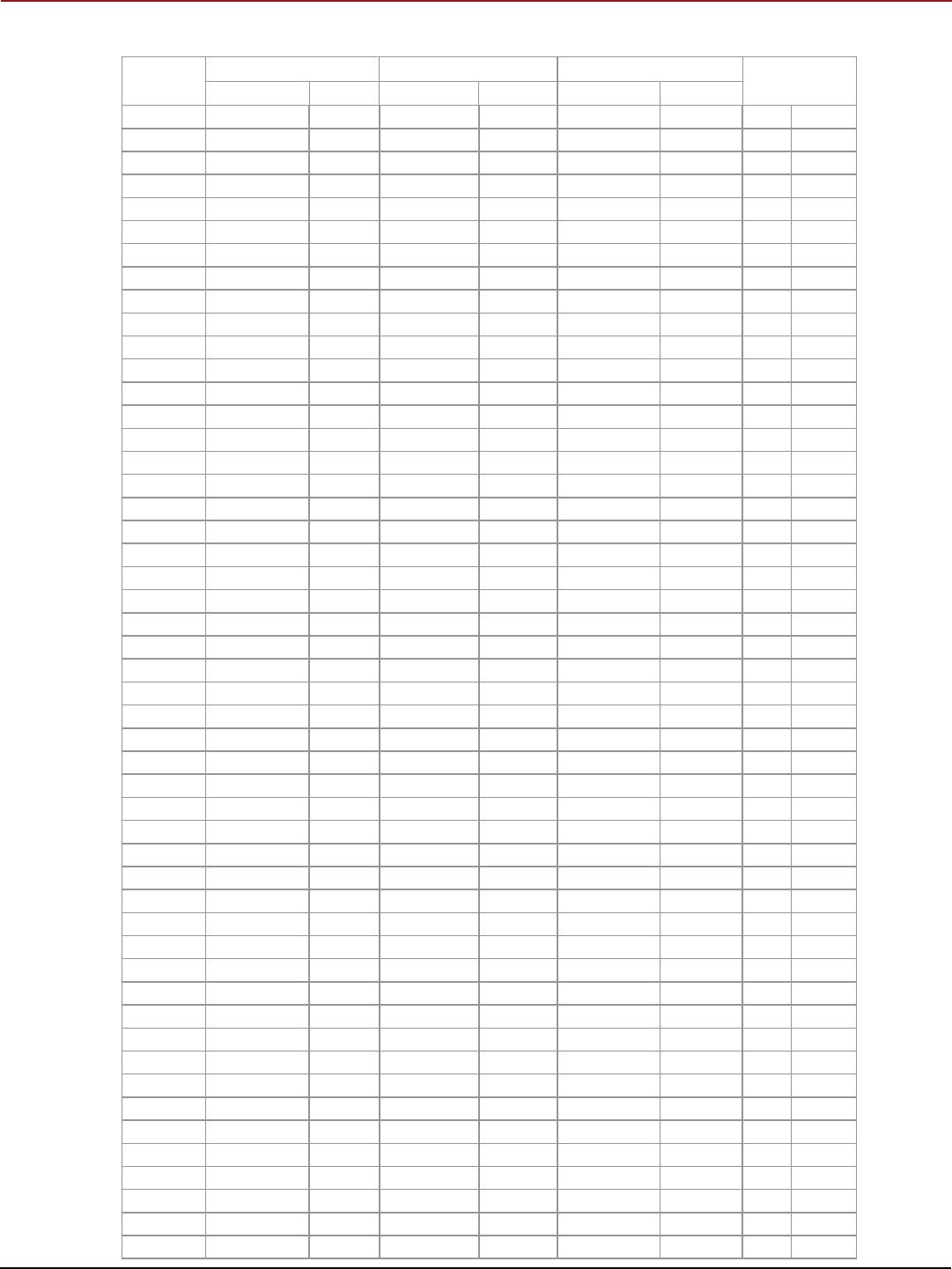

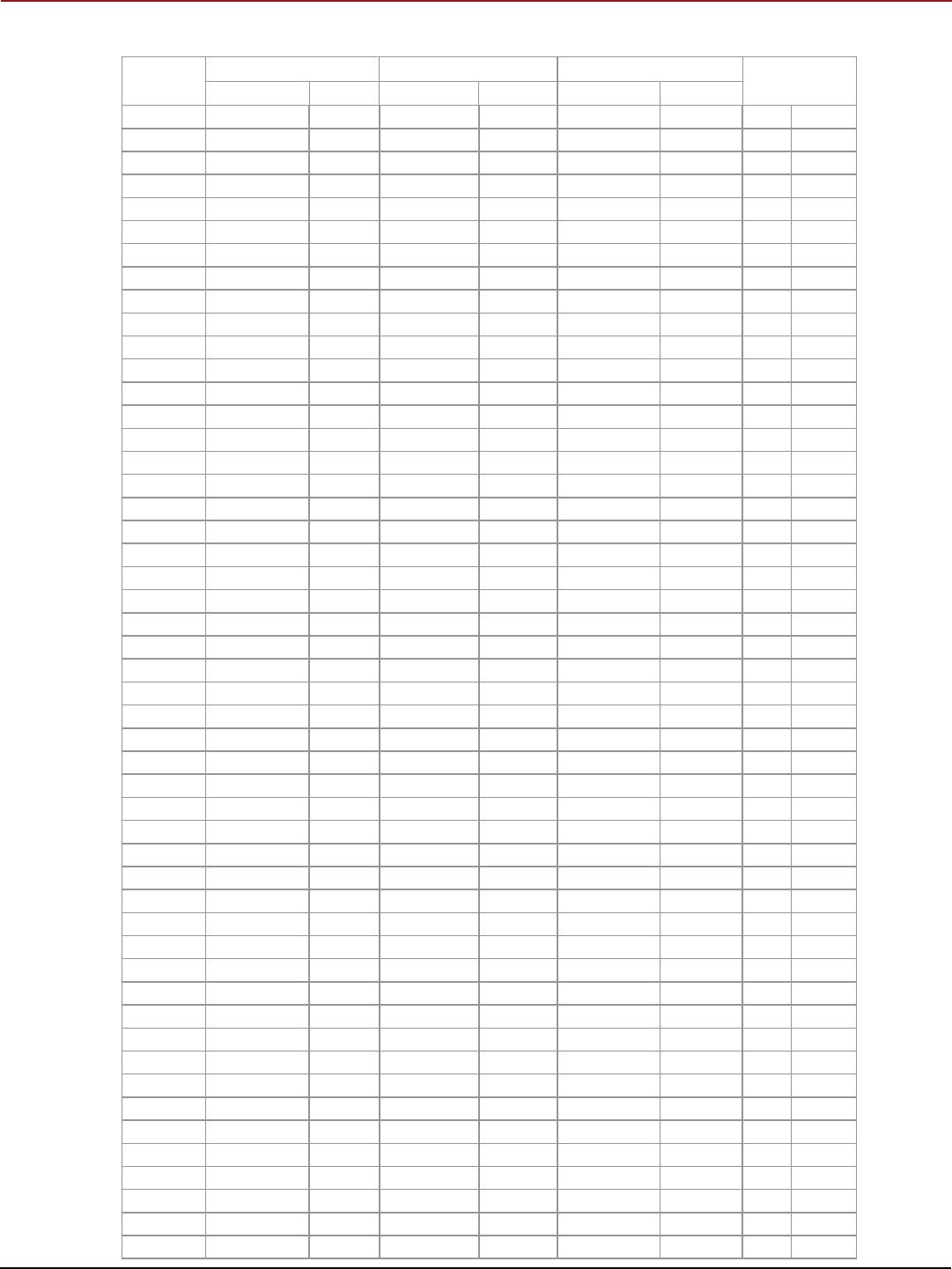

Diam. (D) Length (L) Terminals (S) Typical Weight

Case Code ±.031 Inches ±.78 mm ±.062 Inches ±1.57 mm ±0.015 Inches ±.38 mm

oz g

AK 1.375 34.93 1.625 41.28 0.50 12.70 1.9 54

AA 1.375 34.93 2.125 53.98 0.50 12.70 2.0 57

AH 1.375 34.93 2.625 66.68 0.50 12.70 2.7 77

AB 1.375 34.93 3.125 79.38 0.50 12.70 3.3 94

AJ 1.375 34.93 3.625 92.08 0.50 12.70 3.8 108

AC 1.375 34.93 4.125 104.78 0.50 12.70 4.4 125

AD 1.375 34.93 4.625 117.48 0.50 12.70 5.1 145

AE 1.375 34.93 5.125 130.18 0.50 12.70 6.8 193

AF 1.375 34.93 5.625 142.88 0.50 12.70 8.1 230

EA 1.750 44.45 2.125 53.98 0.75 19.05 2.7 76

EH 1.750 44.45 2.625 66.68 0.75 19.05 3.8 108

EB 1.750 44.45 3.125 79.38 0.75 19.05 5.1 145

EJ 1.750 44.45 3.625 92.08 0.75 19.05 6.8 193

EC 1.750 44.45 4.125 104.78 0.75 19.05 8.1 230

ED 1.750 44.45 4.625 117.48 0.75 19.05 9.0 255

EE 1.750 44.45 5.125 130.18 0.75 19.05 9.5 269

EF 1.750 44.45 5.625 142.88 0.75 19.05 10.5 298

BA 2.000 50.80 2.125 53.98 0.88 22.23 5.4 153

BH 2.000 50.80 2.625 66.68 0.88 22.23 6.1 173

BB 2.000 50.80 3.125 79.38 0.88 22.23 6.8 193

BJ 2.000 50.80 3.625 92.08 0.88 22.23 8.2 232

BC 2.000 50.80 4.125 104.78 0.88 22.23 9.5 269

BD 2.000 50.80 4.625 117.48 0.88 22.23 10.3 292

BE 2.000 50.80 5.125 130.18 0.88 22.23 10.7 303

BF 2.000 50.80 5.625 142.88 0.88 22.23 13.0 369

CH 2.500 63.50 2.625 66.68 1.13 28.58 9.2 261

CB 2.500 63.50 3.125 79.38 1.13 28.58 10.4 295

CJ 2.500 63.50 3.625 92.08 1.13 28.58 12.7 361

CC 2.500 63.50 4.125 104.78 1.13 28.58 15.0 425

CD 2.500 63.50 4.625 117.48 1.13 28.58 17.2 488

CE 2.500 63.50 5.125 130.18 1.13 28.58 19.3 547

CF 2.500 63.50 5.625 142.88 1.13 28.58 21.4 607

DB 3.000 76.20 3.125 79.38 1.25 31.75 16.7 473

DJ 3.000 76.20 3.625 92.08 1.25 31.75 20.0 567

DC 3.000 76.20 4.125 104.78 1.25 31.75 22.2 629

DD 3.000 76.20 4.625 117.48 1.25 31.75 25.5 723

DE 3.000 76.20 5.125 130.18 1.25 31.75 30.0 850

DF 3.000 76.20 5.625 142.88 1.25 31.75 31.9 904

DM 3.000 76.20 6.625 168.28 1.25 31.75 34.4 933.5

DP 3.000 76.20 5.875 149.23 1.25 31.75 32.8 931

DN 3.000 76.20 7.625 193.68 1.25 31.75 39.5 1119

DG 3.000 76.20 8.625 219.08 1.25 31.75 43.3 1227

FC 3.500 88.90 4.125 104.78 1.25 31.75 30.0 850

FD 3.500 88.90 4.625 117.48 1.25 31.75 34.4 976

FE 3.500 88.90 5.125 130.18 1.25 31.75 40.5 1148

FF 3.500 88.90 5.625 142.88 1.25 31.75 43.1 1221

FP 3.500 88.90 5.875 149.23 1.25 31.75 44.3 1257

FN 3.500 88.90 7.625 193.68 1.25 31.75 53.3 1512

FG 3.500 88.90 8.625 219.08 1.25 31.75 58.5 1658

FM 3.500 88.90 6.625 168.28 1.25 31.75 46.4 1315.4

Uninsulated Case Dimensions For insulated case, add 0.024”(0.610 mm) to “D”and 0.030”(0.762 mm) to height.

Type DCMC 85 °C High Capacitance, Screw Terminal, Aluminum

Highest Capacitance Screw Terminal Type

CDM Cornell Dubilier • 140 Technology Place • Liberty, SC 29657 • Phone: (864)843-2277 • Fax: (864)843-3800