Revision: 201304

63

Note: Rated Continuous Working Voltage (RCWV) = Power Rating x Resistance Value or Max. working voltage listed above, whichever less.

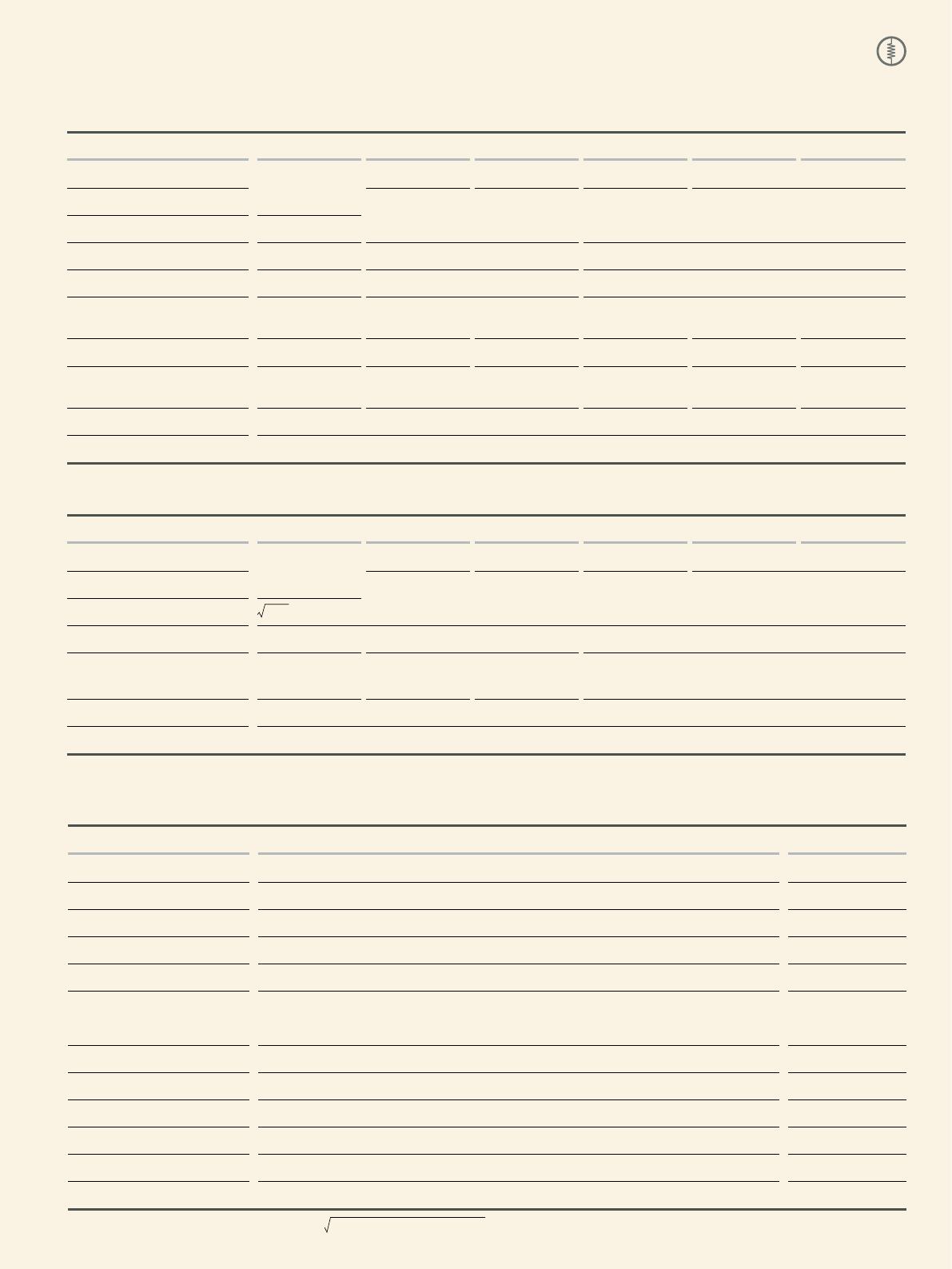

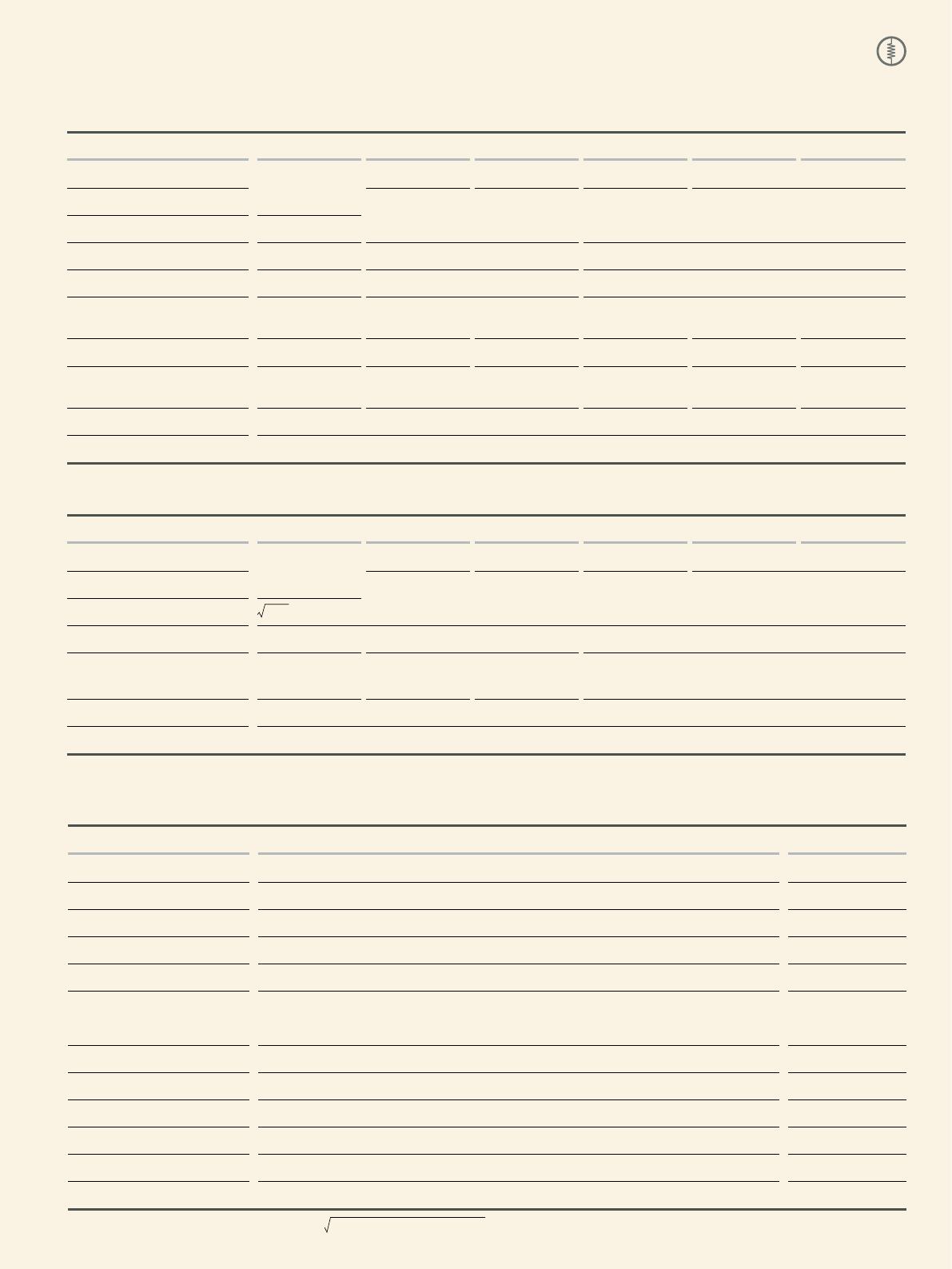

ELECTRICAL CHARACTERISTICS

NORMAL STYLE

STYLE SQM200 SQM300 SQM500 SQM700 SQM10A SQM10S

Power Rating at 40°C 3W 5W 7W 10W

Power Rating at 70°C 2W

Maximum Working Voltage 250V 350V 500V

Maximum Overload Voltage 500V 700V 1,000V

Voltage Proof on Insulation 500V 700V 1,000V

Resistance Range

(Ceramic based wirewound)

0.1Ω - 36Ω 0.1Ω - 68Ω 0.1Ω - 130Ω 0.1Ω - 330Ω 0.1Ω - 510Ω 0.1Ω - 270Ω

Resistance Range (Metal Oxide Film)

39Ω - 1MΩ 75Ω - 1MΩ 150Ω - 1MΩ 360Ω - 1MΩ 560Ω - 1MΩ 300Ω - 1MΩ

Resistance Range

(Fiberglass based wirewound)

0.1Ω - 1KΩ 0.1Ω - 4.7KΩ 0.1Ω - 10KΩ 0.1Ω - 16KΩ 0.1Ω - 4.7KΩ

Operating Temp. Range -55°C to +155°C

Temperature Coefcient ±300ppm/°C

NON-INDUCTIVE STYLE

STYLE NSM200 NSM300 NSM500 NSM700 NSM10A NSM10S

Power Rating at 40°C 3W 5W 7W 10W

Power Rating at 70°C 2W

Maximum Working Voltage

Voltage Proof on Insulation 500V 700V 1,000V

Resistance Range

(Ceramic based wirewound)

0.1Ω - 10Ω 0.1Ω - 30Ω 0.15Ω - 65Ω 0.27Ω - 100Ω

Operating Temp. Range -55°C to +155°C

Temperature Coefcient ±300ppm/°C

Note: Special value is available on request

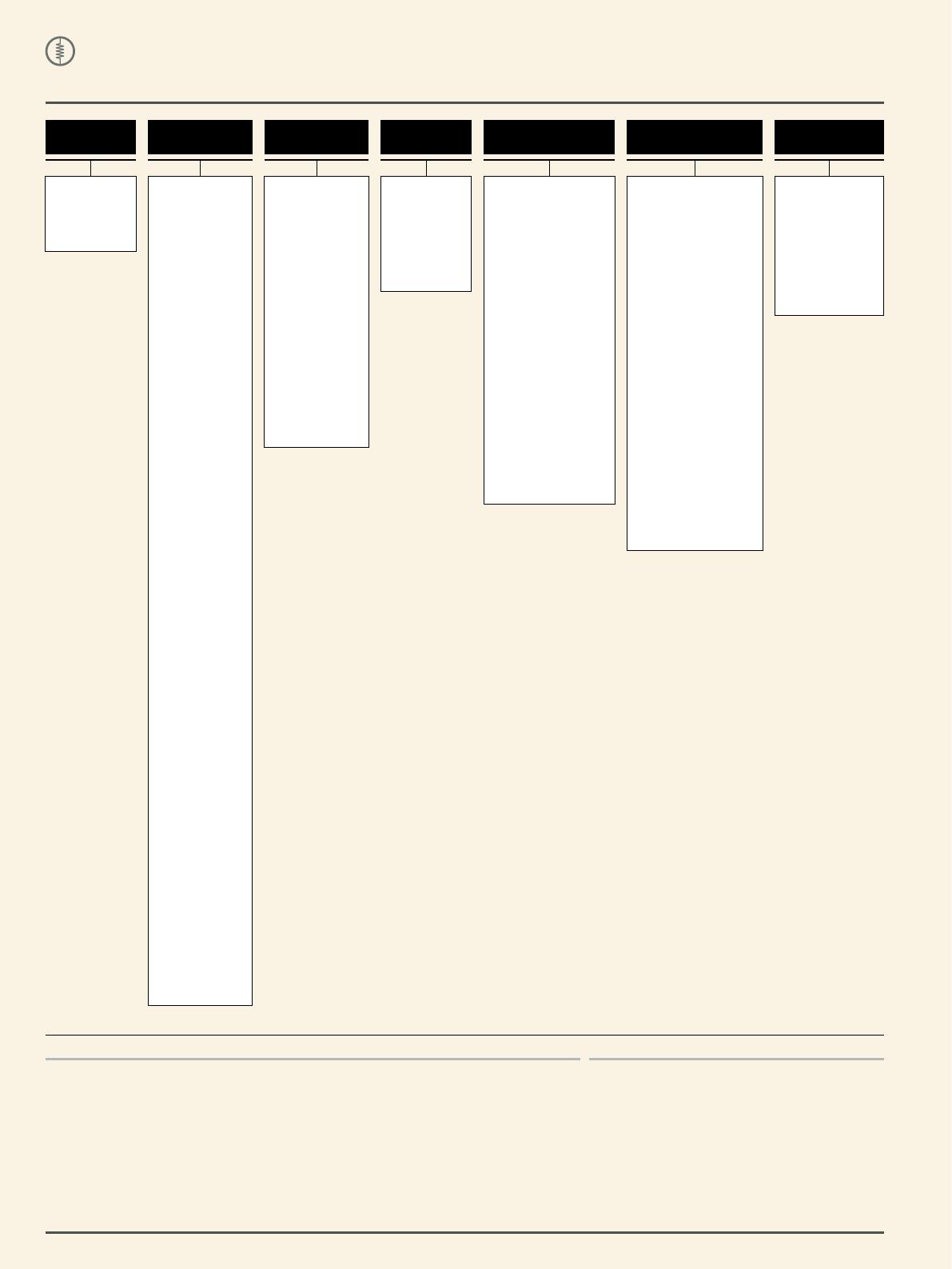

ENVIRONMENTAL CHARACTERISTICS

PERFORMANCE TEST TEST METHOD APPRAISE

Short Time Overload IEC 60115-1 4.13 2.5 times RCWV for 5 Sec. ±2.0%+0.05Ω

Voltage Proof on Insulation IEC 60115-1 4.7 in V-block for 60 Sec., test voltage by type By type

Temperature Coefcient IEC 60115-1 4.8 -55°C to +155°C By type

Insulation Resistance IEC 60115-1 4.6 in V-block for 60 Sec. >1,000MΩ

Solderability IEC 60115-1 4.17 235±5°C for 3±0.5 Sec. 95% Min. coverage

Solvent Resistance of Marking IEC 60115-1 4.30 IPA for 5±0.5 Min. with ultrasonic

No deterioration of

coatings and markings

Robustness of Terminations IEC 60115-1 4.16 Direct load for 10 Sec. in the direction of the terminal leads ≥2.5kg (24.5N)

Periodic-pulse Overload IEC 60115-1 4.39 4 times RCWV 10,000 cycles (1 Sec. on, 25 Sec. off) ±2.0%+0.05Ω

Damp Heat Steady State IEC 60115-1 4.24 40±2°C, 90-95% RH for 56 days, loaded with 0.1 times RCWV ±5.0%+0.05Ω

Endurance at 70°C IEC 60115-1 4.25 70±2°C at RCWV for 1,000 Hr. (1.5 Hr. on, 0.5 Hr. off) ±5.0%+0.05Ω

Temperature Cycling IEC 60115-1 4.19 -55°C Room Temp. +155°C Room Temp. (5 cycles) ±2.0%+0.05Ω

Resistance to Soldering Heat IEC 60115-1 4.18 260±3°C for 10±1 Sec., immersed to a point 3±0.5mm from the body ±1.0%+0.05Ω