Bulk Metal

®

Foil Ultra High Technology Precision Trimming Potentiometers,

3

/

8

" Square, RJ24 Style, Designed to Meet or Exceed the Requirements of

MIL-PRF-39035, Char. H with a Smooth and Unidirectional Output

Accutrim™ 1260 (RJ24 Style)

Vishay Foil Resistors

Document Number: 63054 For any questions, contact: foil@vishaypg.com www.vishayfoilresistors.com

Revision: 8-Nov-12 1

INTRODUCTION

Vishay Foil Resistors (VFR) precision trimmers have the

Bulk Metal

®

Foil resistive element which possesses a unique

inherent temperature and load life stability. Plus, their

advanced virtually back lash-free adjustment mechanism

makes them easy to set quickly and accurately and keeps

the setting exactly on target.

FEATURES

Temperature coefficient of resistance (TCR):

± 10 ppm/°C (- 55 °C to + 150 °C ref. at + 25 °C);

through the wiper

(2)

; ± 25 ppm/°C (see table 2 for

low values)

A

smooth and unidirectional resistance with

leadscrew adjustment

Load life stability: 0.1 % typical R, 1.0 % maximum R

under full rated power at + 85 °C for 10 000 h

Se

ttability: 0.05 % typical; 0.1 % maximum

Se

tting stability: 0.1 % typical; 0.5 % maximum

Power rating: 0.25 W at + 85 °C

R

esistance range: 5 to 10 k

R

esistance tolerance: ± 5 %, ± 10 %

“O”-ring prevents ingress of fluids during any board

cleaning operation

El

ectrostatic discharge (ESD) up to 25 000 V

T

erminal finish: tin/lead or lead free

CERMET

Wiper Travel

Resistance

Wiper Travel

Resistance

BULK METAL

FOIL

WIREWOUND

Wiper Travel

Resistance

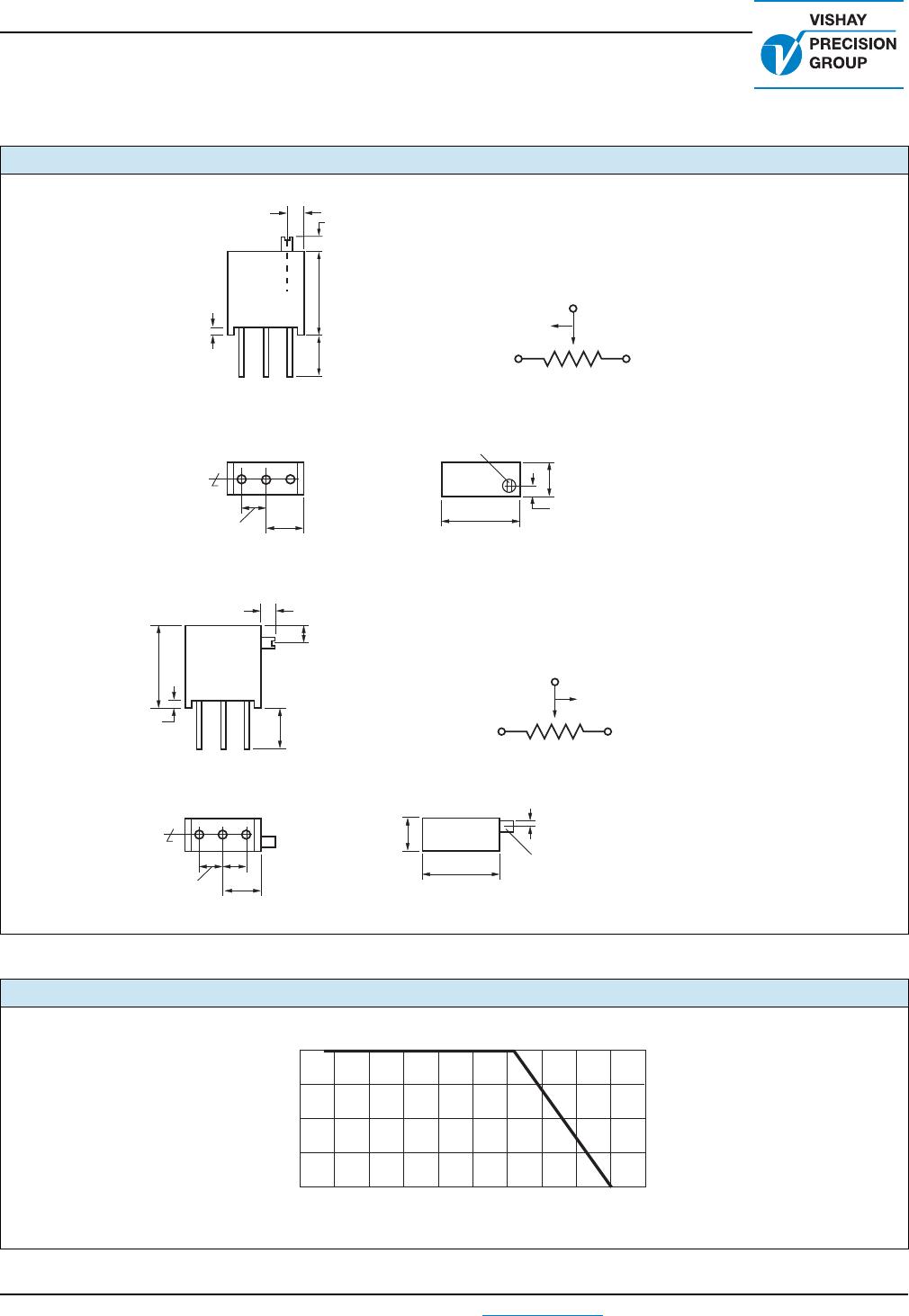

TABLE 1 - MODEL SELECTION

MODEL TERMINATION STYLE AVERAGE WEIGHT (g) POWER RATING at + 85 °C AMBIENT NO. OF TURNS

1260

W-edge mount, top adjust

0.4 0.25 W 21 ± 2

X-edge mount, side adjust

Note

• See figure 1

TABLE 2 - 1260 (RJ24 STYLE) SERIES

ELECTRICAL SPECIFICATIONS

Temperature Coefficient of

Resistance (TCR) 50 to

10 k

End-to-end

(1)

± 10 ppm/°C maximum

(- 55 °C to + 150 °C,

+ 25 °C ref.)

Temperature Coefficient of

Resistance (TCR) 5 , 10

and 20

Through the wiper

(2)

± 20 ppm/°C

± 25 ppm/°C

Stability

Load life at 10 000 h

0.1 % typical R

1.0 % maximum R

(under full rated power

of 0.25 W at + 85 °C)

Power Rating

(3)

0.25 W at + 85 °C

Settability

0.05 % typical;

0.1 % maximum

Setting Stability 0.1 % typical;

0.5 % maximum

Contact Resistance

Variation - CRV (noise)

3

typical;

10

maximum

Hop-off

0.25 % typical;

1.0 % maximum

High-Frequency Operation

Rise/decay time

Inductance

Capacitance

1 ns without ringing

0.08 µH typical

0.5 pF typical

Operating Temperature Range - 55 °C to + 150 °C

TABLE 3 - VALUES VS. TOLERANCES

STANDARD RESISTANCE VALUES

(in )

STANDARD

TOLERANCE

5, 10 ± 10 %

20, 50, 100, 200, 500, 1K, 2K, 5K, 10K ± 5 %

TABLE 4 - MECHANICAL SPECIFICATIONS

Adjustment Turns

21 ±

2

Mechanical Stops

Wiper idles - no discontinuity

Internal Terminations

All welded - no flux

Case Material

Diallyl-phthalate: black (DAP)

Shaft Torque

3 oz. in. maximum

Backlash

0.005 % typical