MBA/SMA 0204, MBB/SMA 0207, MBE/SMA 0414 - Professional

www.vishay.com

Vishay Beyschlag

Revision: 12-Feb-16

11

Document Number: 28766

For technical questions, contact: filmresistorsleaded@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

TESTS PROCEDURES AND REQUIREMENTS

All tests are carried out in accordance with the following

specifications:

• EN 60115-1, generic specification (includes tests)

• EN 140100, sectional specification (includes schedule for

qualification approval)

• EN 140101-806 (successor of CECC 40101-806), detail

specification (includes schedule for conformance

inspection)

The test and requirements table contains only the most

important tests. For the full test schedule refer to the

documents listed above.

The tests are carried out in accordance with IEC 60068-2-xx

test method and under standard atmospheric conditions in

accordance with IEC 60068-1, 5.3.

Climatic category LCT / UCT / 56 (rated temperature range:

lower category temperature, upper category temperature;

damp heat, steady state, test duration: 56 days) is valid.

Unless otherwise specified the following values apply:

• Temperature: 15 °C to 35 °C

• Relative humidity: 45 % to 75 %

• Air pressure: 86 kPa to 106 kPa (860 mbar to 1060 mbar).

For performing some of the tests, the components are

mounted on a test board in accordance with IEC 60115-1,

4.31.

In Test Procedures and Requirements table, only the tests

and requirements are listed with reference to the relevant

clauses of IEC 60115-1 and IEC 60068-2-xx test methods.

A short description of the test procedure is also given.

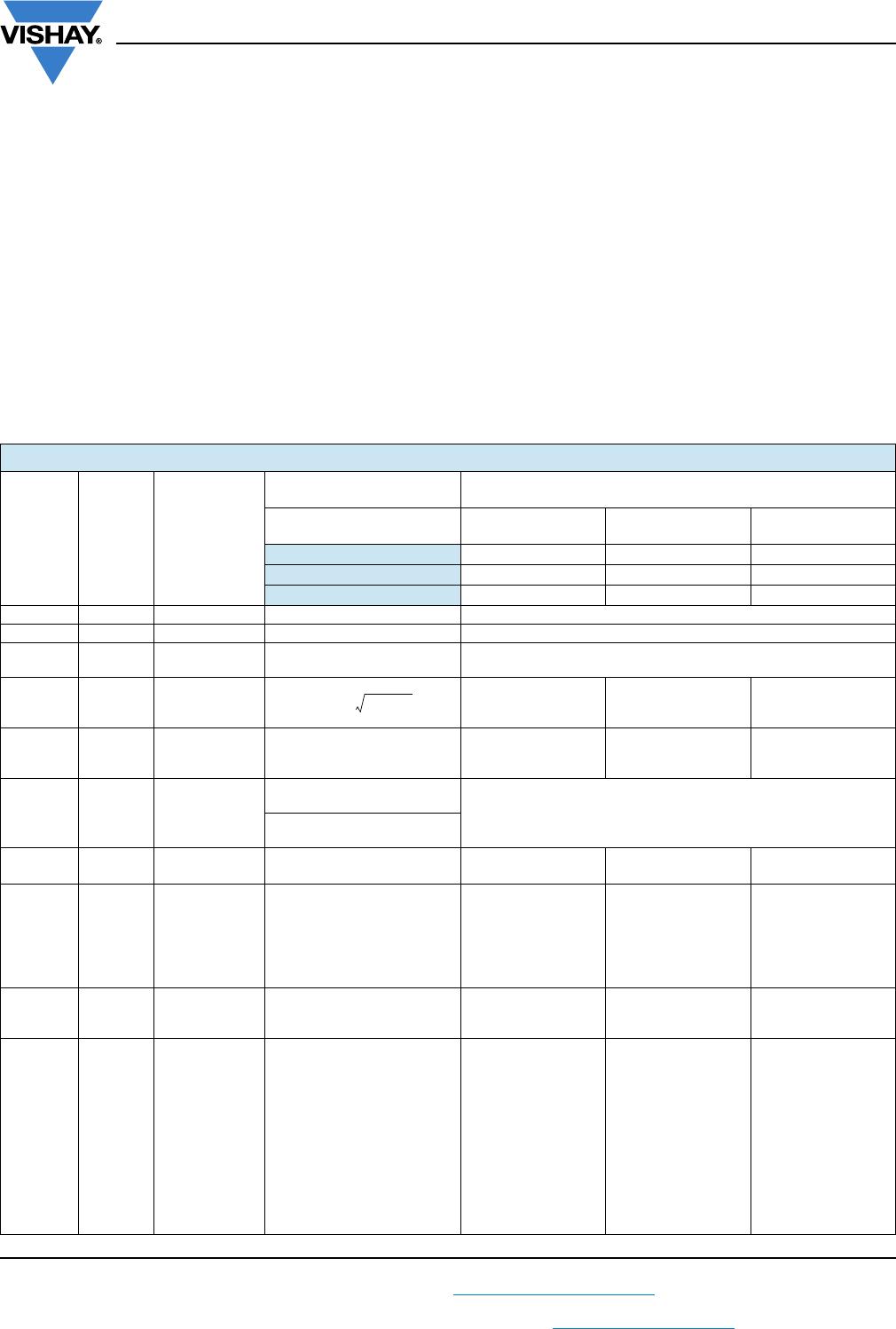

TEST PROCEDURES AND REQUIREMENTS

IEC

60115-1

CLAUSE

IEC

60068-2

TEST

METHOD

TEST

PROCEDURE

REQUIREMENTS PERMISSIBLE CHANGE

(R max.)

Stability for product types:

STABILITY

CLASS 0.5

STABILITY

CLASS 1

STABILITY

CLASS 2

MBA/SMA 0204 1 to 332 k 0.22 to < 1 > 332 k

MBB/SMA 0207 1 to 1 M 0.22 to < 1 > 1 M

MBE/SMA 0414 1 to 2.43 M 0.22 to < 1 > 2.43 M

4.5 - Resistance - ± 5 % R; ± 1 % R; ± 0.5 % R

4.7 - Voltage proof U

RMS

= U

ins

; 60 s No flashover or breakdown

4.8 -

Temperature

coefficient

At (20 / -55 / 20) °C

and (20 / 155 / 20) °C

± 50 ppm/K; ± 25 ppm/K

4.13 -

Short time

overload

Room temperature;

U= 2.5x or

U = 2xU

max.

; 5 s

± (0.1 %R +0.01 )

no visible damage

± (0.25 %R +0.05 )

no visible damage

± 0.5 %R

no visible damage

4.16

21 (Ua

1

)

21 (Ub)

21 (Uc)

Robustness

of terminations

Tensile, bending,

and torsion

± (0.1 %R +0.01 )± (0.25 %R +0.05 )± 0.5 %R

4.17 20 (Ta) Solderability

+235 °C; 2 s; solder bath

method; SnPb40

Good tinning

(> 95 % covered, no visible damage)

+245 °C; 3 s; solder bath

method; SnAg3Cu0.5

4.18.2 20 (Tb)

Resistance to

soldering heat

Unmounted components;

(260 ± 5) °C; (10 ± 1) s

± (0.1 %R +0.01 )

no visible damage

± (0.25 %R +0.05 )

no visible damage

± 0.5 %R

no visible damage

4.19 14 (Na)

Rapid change

of temperature

30min at -55 °C

30min at 155°C

5 cycles ± (0.1 %R +0.01 )± (0.25 %R +0.05 )± 0.5 %R

MBA/SMA 0204: 500 cycles

MBB/SMA 0207: 200 cycles

MBE/SMA 0414: 100 cycles

± (0.5 %R +0.05 ) ± (0.5 %R +0.05 ) ± (0.5 %R +0.05 )

4.22 6 Vibration

10 sweep cycles per

direction; 10 Hz to2000 Hz

1.5 mm or 200 m/s

2

± (0.1 %R +0.01 )± (0.25 %R +0.05 )± 0.5 %R

4.23

Climatic

sequence:

4.23.2 2 (Ba) Dry heat 155 °C; 16h

4.23.3 30 (Db)

Damp heat,

cyclic

55 °C; 24h;

90% to100%RH; 1 cycle

4.23.4 1 (Aa) Cold -55 °C; 2h

4.23.5 13 (M)

Low air

pressure

8.5kPa; 2h;

15 °Cto35 °C

4.23.6 30 (Db)

Damp heat,

cyclic

55°C; 5days;

95 %to100%RH; 5 cycles

± (0.5 %R +0.05 )

no visible damage

± (1 %R +0.05 )

no visible damage

± 2 %R

no visible damage

4.23.7 DC load apply rated power for 1 min