CUSTOMER DRAWING

Rev. Date:

15-Apr-11

Rev.:

D1

Document No.

RHW

Sheet:

2 of 2

Print Date: 18-Apr-11 If this document is printed it becomes uncontrolled. Check for the latest revision.

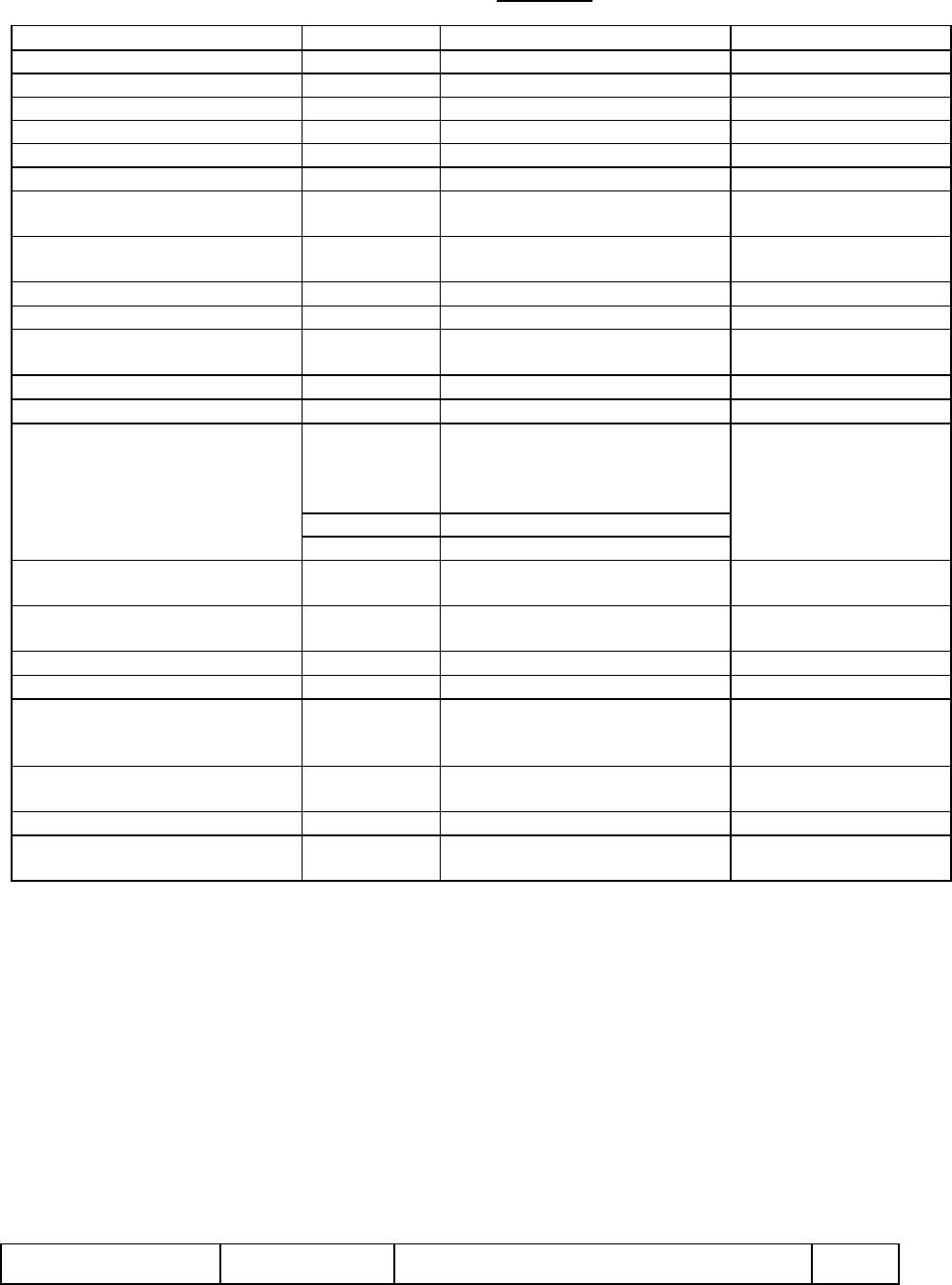

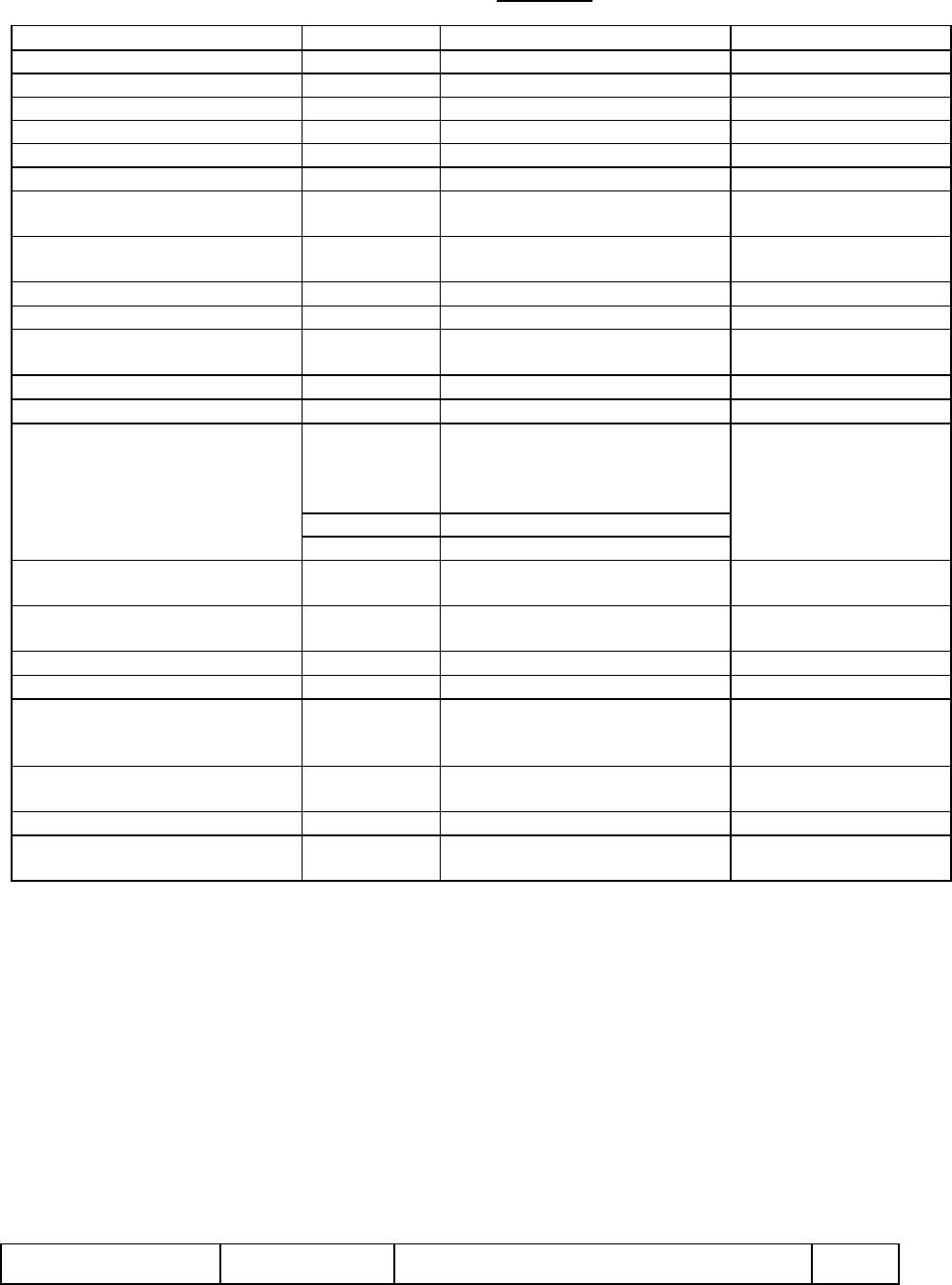

Table 2: Properties

Property Unit Requirement Test Method

Dimensions Inch (mm) Table 1 ASTM D412

Tensile Strength PSI (MPa) 1750 minimum (12) ASTM D412

Ultimate Elongation Percent 350 minimum ASTM D412

Longitudinal Change Percent +5 to -15 maximum ASTM D792

Specific Gravity 1.2 maximum ASTM D792

Hardness Shore D 40-60 ASTM D2240

Low Temperature Flexibility No cracking ASTM D2671

4 hrs @ -55°C

Heat Resistance 168 h @150°C

Percent 350 minimum ASTM D2671

followed by Ult. Elongation

ELECTRICAL

Dielectric Strength V/mil (kV/cm) 300 minimum (120) ASTM D149

Dielectric Withstand Volt/Minute No Breakdown UL 486D

2200 V for 1 minute

Volume Resistivity Ohm-cm

1 X 10

12

minimum

ASTM D257

CHEMICAL

Fluid Resistance

168 hrs @ 23°C

Immersion in VDE 0370 oil

followed by tests for:

Tensile Strength PSI 80% of original minimum ASTM D2671

Elongation Percent 80% of original minimum

Corrosive Effect Non Corrosive ASTM D2671, Proc. A

16 hrs @ 150°C

Water Absorption Percent 0.10 maximum ASTM D570

24 hrs @ 23°C

ADHESIVE

Softening point °C 90+/-10 ASTM E28

Adhesive Peel Strength

- Tubing to copper PLI 10 minimum ASTM DI000

- Tubing to polyethylene PLI 10 minimum

Adhesive shear PSI 150 minimum ASTM D1002

- AL to AL

Water absorption Percent 0.5 maximum ASTM D570

Corrosive Effect Non Corrosive ASTM D2671

16 hrs @ 121°C See 79, Proc, A