Notes:

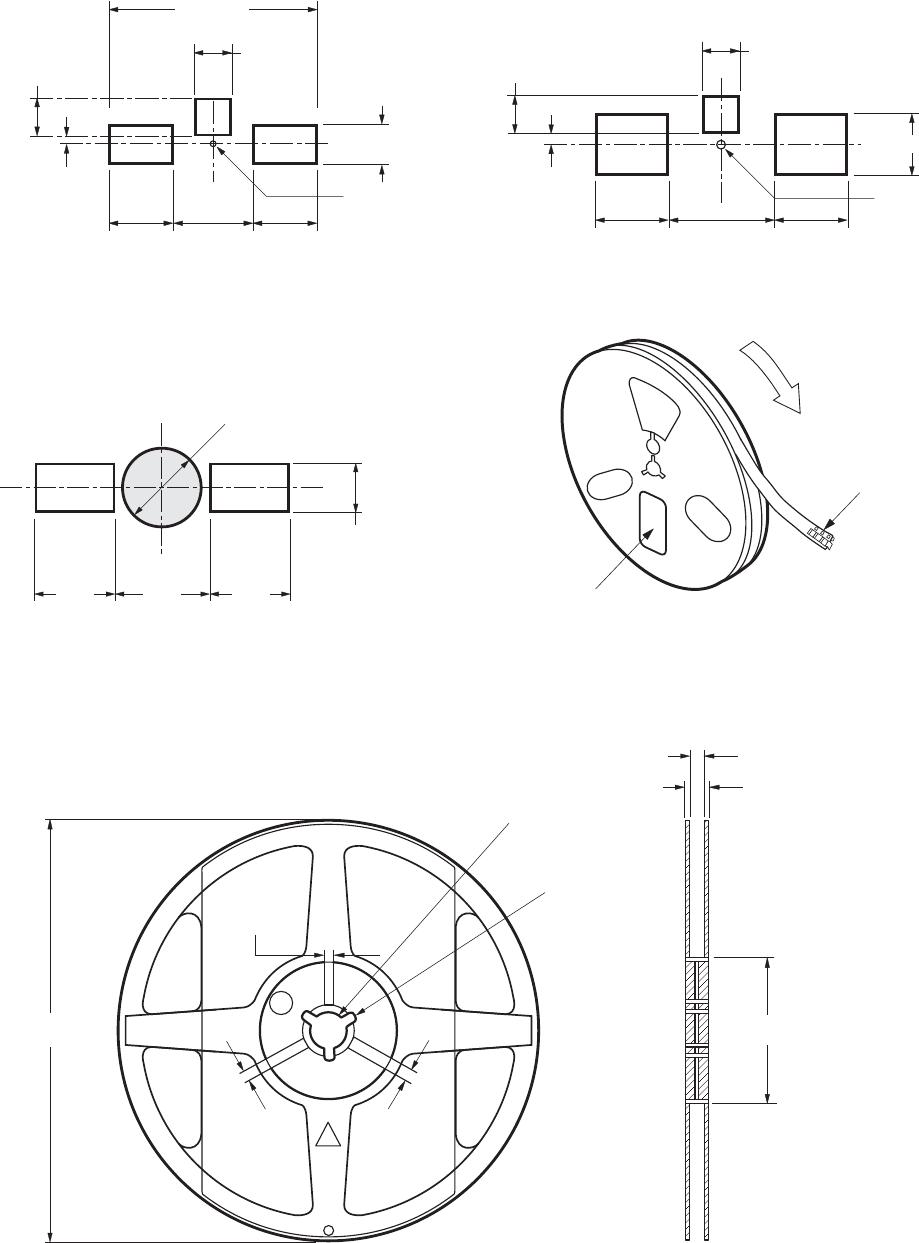

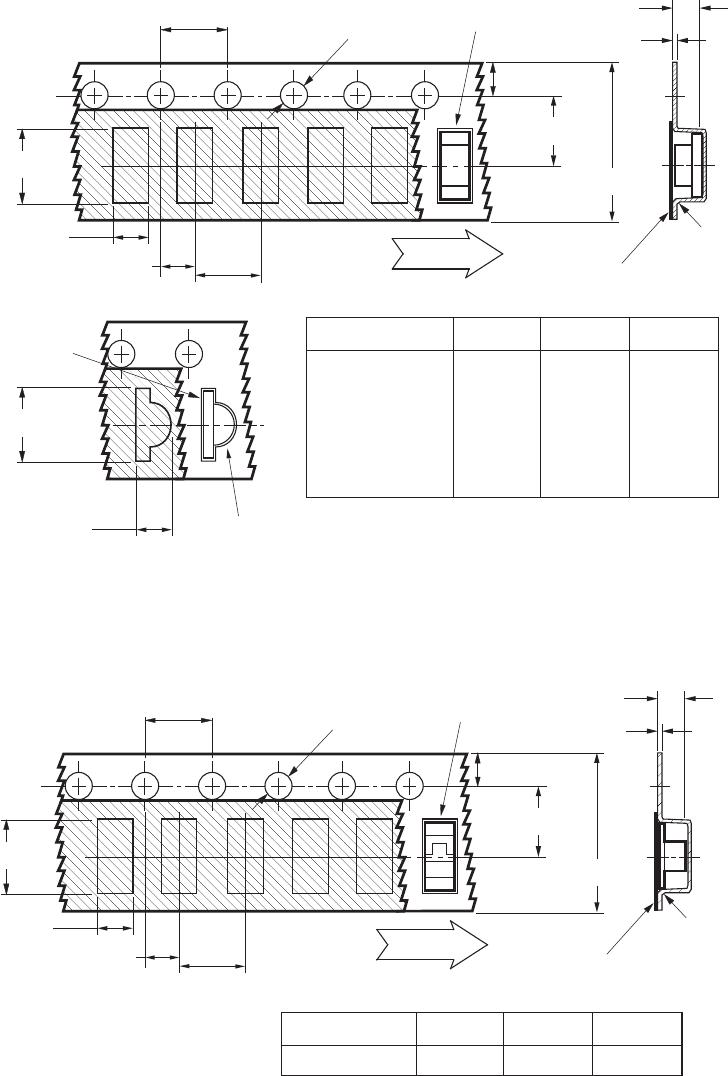

1. All dimensions in millimeters (inches).

2. Tolerance is ±0.1 mm (±0.004 in.)unless otherwise speci ed.

Figure 20. Tape leader and trailer dimensions.

Convective IR Re ow Soldering

For more information on IR re ow

soldering, refer to Application Note

1060, Surface Mounting SMT LED

Indicator Components.

Storage Condition: 5 to 30˚ C

@ 60% RH max.

Baking is required under the

condition:

a) Humidity Indicator Card is

>10% when read at 23 ± 5°C.

b) Device exposed to factory

conditions <30°C/60% RH

more than 672 hours.

Baking recommended condition: 60

+/– 5˚C for 20 hours.

END START

THERE SHALL BE A

MINIMUM OF 160 mm

(6.3 INCH) OF EMPTY

COMPONENT POCKETS

SEALED WITH COVER

TAPE.

MOUNTED WITH

COMPONENTS

THERE SHALL BE A

MINIMUM OF 160 mm

(6.3 INCH) OF EMPTY

COMPONENT POCKETS

SEALED WITH COVER

TAPE.

MINIMUM OF

230 mm

(9.05 INCH)

MAY CONSIST

OF CARRIER

AND/OR

COVER TAPE.

For product information and a complete list of distributors, please go to our website: www.avagotech.com

Avago, Avago Technologies, and the A logo are trademarks of Avago Technologies in the United States and other countries.

Data subject to change. Copyright © 2005-2012 Avago Technologies. All rights reserved. Obsoletes 5989-4806EN

AV02-0551EN - March 5, 2012