118

6

Multi-Layer Organic Capacitors

MECHANICAL SPECIFICATIONS

TEST CONDITIONS REQUIREMENT

Life (Endurance) MIL-STD-202F 125°C, 2U

R

, 1000 hours No visible damage ⌬C/C ≤2% for C≥5pF

Method 108A ⌬C/C ≤0.25pF for C<5pF

Accelerated Damp Heat Steady 85°C, 85% RH, U

R

, 1000 hours No visible damage ⌬C/C ≤2% for C≥5pF

State MIL-STD-202F Method 103B ⌬C/C ≤0.25pF for C<5pF

Temperature Cycling –55°C to +125°C, 15 cycles – MLO

TM

No visible damage ⌬C/C ≤2% for C≥5pF

MIL-STD-202F Method 107E ⌬C/C ≤0.25pF for C<5pF

MIL-STD-883D Method 1010.7

Resistance to Solder Heat 260°C ± 5°C for 10 secs. C remains within initial limits

IEC-68-2-58

ENVIRONMENTAL CHARACTERISTICS

TABLE I: CASE SIZE ML03

Cap. pF Cap. Tol. WVDC

0.1 P, A, B 50, 250, 500

0.2 P, A, B 50, 250, 500

0.3 P, A, B 50, 250, 500

0.4 P, A, B 50, 250, 500

0.5 P, A, B, C 50, 250, 500

0.6 P, A, B, C 50, 250, 500

0.7 P, A, B, C 50, 250, 500

0.8 P, A, B, C 50, 250, 500

0.9 P, A, B, C 50, 250, 500

1.0 P, A, B, C 50, 250, 500

1.1 P, A, B, C 50, 250, 500

1.2 P, A, B, C 50, 250, 500

Cap. pF Cap. Tol. WVDC

1.3 P, A, B, C 50, 250, 500

1.4 P, A, B, C 50, 250, 500

1.5 P, A, B, C 50, 250, 500

1.6 P, A, B, C 50, 250, 500

1.7 P, A, B, C 50, 250, 500

1.8 P, A, B, C 50, 250, 500

1.9 P, A, B, C 50, 250, 500

2.0 P, A, B, C 50, 250, 500

2.2 P, A, B, C 50, 250, 500

2.4 P, A, B, C 50, 250, 500

2.5 P, A, B, C 50, 250, 500

2.7 P, A, B, C 50, 250

Cap. pF Cap. Tol. WVDC

3.0 P, A, B, C 50, 250

3.3 P, A, B, C 50, 250

3.6 P, A, B, C 50, 250

3.9 P, A, B, C 50, 250

TEST CONDITIONS REQUIREMENT

Solderability IEC-68-2-58 Components completely immersed in Terminations to be well tinned, minimum 95%

a solder bath at 235°C for 2 secs. coverage

Leach Resistance IEC-68-2-58 Components completely immersed in Dissolution of termination faces ≤15% of area

a solder bath at 260±5°C for 60 secs. Dissolution of termination edges ≤25% of

length

Adhesion MIL-STD-202F A force of 5N applied for 10 secs. No visible damage

Method 211A

Termination Bond Strength Tested as shown in diagram No visible damage ⌬C/C ≤2% for C≥5pF

IEC-68-2-21 Amend. 2 ⌬C/C ≤0.25pF for C<5pF

Robustness of Termination A force of 5N applied for 10 secs. No visible damage

IEC-68-2-21 Amend. 2

Storage 12 months minimum with components Good solderability

stored in “as received” packaging

Life (Endurance) 125°C, 2U

R

, 1000 hours

Accelerated Damp 85°C, 85% RH, U

R

,

Heat Steady State 1000 hours.

QUALITY & RELIABILITY

MLO

TM

capacitors utilize high density interconnect wiring

technology on well established low loss organic materials.

FINAL QUALITY INSPECTION

Finished parts are tested for standard electrical parameters

and visual/mechanical characteristics. Each production lot

is 100% evaluated for: capacitance and proof voltage at

2.5 U

R

. In addition, production is periodically evaluated for:

• Average capacitance with histogram printout for

capacitance distribution;

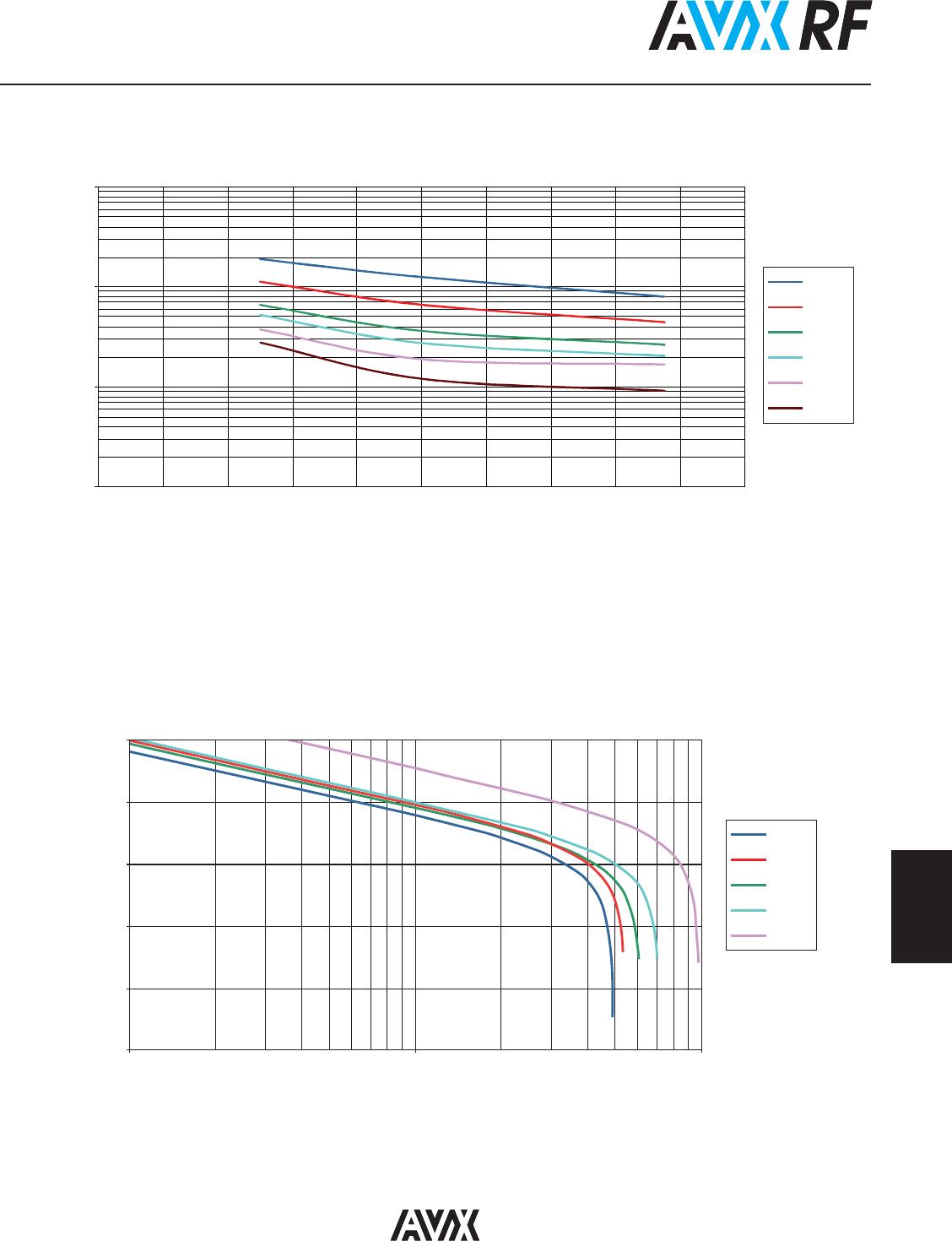

• IR and Breakdown Voltage distribution;

• Temperature Coefficient;

• Solderability;

• Dimensional, mechanical and temperature stability.

QUALITY ASSURANCE

The reliability of these multilayer organic capacitors has

been extensively studied. Various methods and standards

have been used to ensure a high quality component

including JEDEC, Mil Spec and IPC testing. AVX’s quality

assurance policy is based on well established international

industry standards. The reliability of the capacitors is

determined by accelerated testing under the following

conditions: