ERL (Military RLR)

www.vishay.com

Vishay Dale

Revision: 19-Nov-12

1

Document Number: 31023

For technical questions, contact: ff2aresistors@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Metal Film Resistors, Military/Established Reliability,

MIL-PRF-39017 Qualified, Type RLR

FEATURES

• Meets requirements of MIL-PRF-39017

• Failure rate: Verified failure rate (contact factory for current

level)

• Epoxy coated construction provides superior moisture

protection

• Traceability of materials and processing

• Monthly lot acceptance testing

• Very low noise (- 40 dB)

• Extensive stocking program at distributors and factory in

± 1 % and ± 2 % tolerances

• Vishay Dale has complete capability to develop specific

reliability programs designed to customer requirements

Notes

(1)

Extended Resistance Range: DSCC has created a series of drawings intended to support extended resistance ranges left otherwise void by

the discontinuation of MIL-R-39008 RCR carbon composition resistors. Vishay Dale is listed as a resource on these drawings as follows:

• Low inductance: DSCC has created a drawing intended to support a resistor which exhibits low inductance over a frequency range of 1 MHz

to 30 MHz. Vishay Dale is listed as a resource on these drawings as follows:

These drawings can be viewed at: http://www.landandmaritime.dla.mil/Programs/MilSpec/ListDwgs.aspx?DocTYPE=DSCCdwg

(2)

Consult factory for current QPL failure rates

(3)

Hot solder dipped leads

(4)

Continuous working voltage shall be or maximum working voltage, whichever is less.

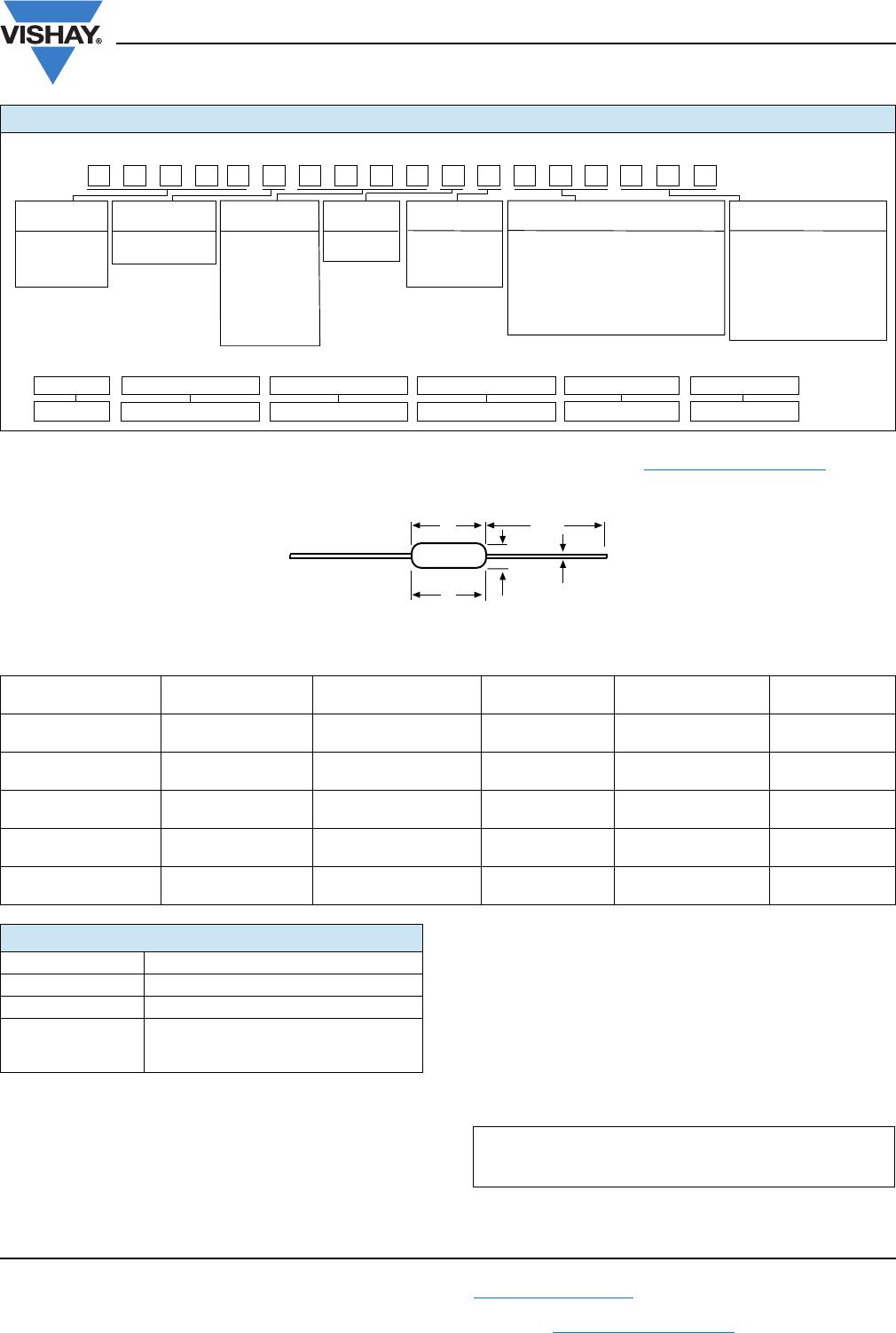

STANDARD ELECTRICAL SPECIFICATIONS

VISHAY

DALE

MODEL

MIL-PRF-39017

STYLE

MIL

SPEC.

SHEET

POWER

RATING

70 °C

W

RESISTANCE

RANGE

(1)

TOLERANCE

± %

TEMPERATURE

COEFFICIENT

±

ppm

/°C

MAXIMUM

WORKING

VOLTAGE

(4)

V

LIFE

FAILURE

RATE

(2)

ERL05,

ERL05..19

(3)

RLR05 05 0.125

4.7 to 301K

1, 2 100 200

M, P, R, S

302K to 1M M, P, R

ERL07,

ERL07..23

(3)

RLR07 01 0.25

1 to 9.76

1, 2 100 250

M

10 to 3.01M M, P, R, S

3.02M to 10M M, P, R

ERL20,

ERL20..11

(3)

RLR20 02 0.50 4.3 to 3.01M 1, 2 100 350 M, P, R

ERL32,

ERL32..1

(3)

RLR32 03 1.0 1 to 2.7M 1, 2 100 500 M, P, R

DSCC

DRAWING

NUMBER

VISHAY DALE

MODEL

POWER RATING

P

70 °C

W

RESISTANCE

RANGE

TOLERANCE

± %

TEMPERATURE

COEFFICIENT

± ppm/°C

MAXIMUM

WORKING

VOLTAGE

V

(4)

98020 ERL05..36, ERL05..37

(3)

0.125 1.1M to 22M 2, 5, 10 350 200

99011 ERL07..100, ERL07..101

(3)

0.25 11M to 22M 2, 5, 10 350 250

98021 ERL20..36, ERL20..37

(3)

0.50 3.3M to 22M 2, 5, 10 350 350

98022 ERL32..36, ERL32..37

(3)

1.0 3M to 22M 2, 5, 10 350 350

97004 ERL62..1, ERL62..2

(3)

2.0

10 to 2.7M

3M to 22M

1, 2, 5, 10

100

350

500

DSCC

DRAWING

NUMBER

VISHAY DALE

MODEL

POWER

RATING

P

70 °C

W

RESISTANCE

RANGE

MAXIMUM

INDUCTANCE

n

H

TOLERANCE

± %

TEMPERATURE

COEFFICIENT

± ppm/°C

MAXIMUM

WORKING

VOLTAGE

V

(4)

96002 ERL07..62 0.25

1 to 10 10

1, 2 100 250

11 to 49.9 8

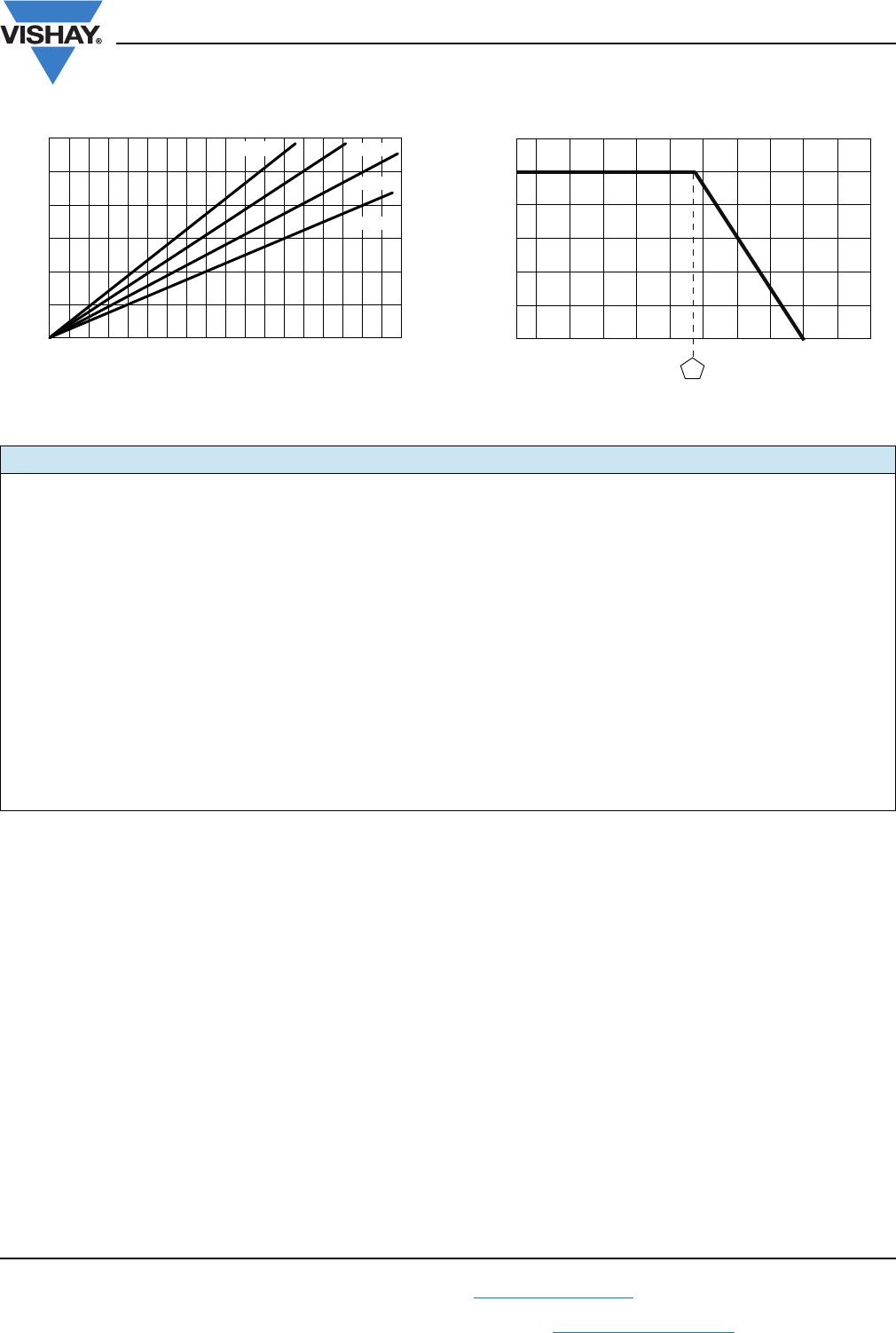

TECHNICAL SPECIFICATIONS

PARAMETER UNIT CONDITION

Voltage Coefficient, max. ppm/V 5/V when measured between 10 % and full rated voltage

Dielectric Strength V

AC

RLR05 = 300; RLR07 and RLR20 = 500; RLR32 = 1000

Insulations Resistance 10

9

min. dry; 10

11

min. after moisture test

Operating Temperature Range °C - 65 to + 150

Terminal Strength lb 2 lb pull test on RLR05; 5 lb pull test on all other sizes

Solderability Continuous satisfactory coverage when tested in accordance with MIL-STD-202, Method 208

Weight g RLR05 = 0.11; RLR07 = 0.35; RLR20 = 0.75; RLR32 = 1.50