Automotive LED Array Driver

A6269

9

Allegro MicroSystems, LLC

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

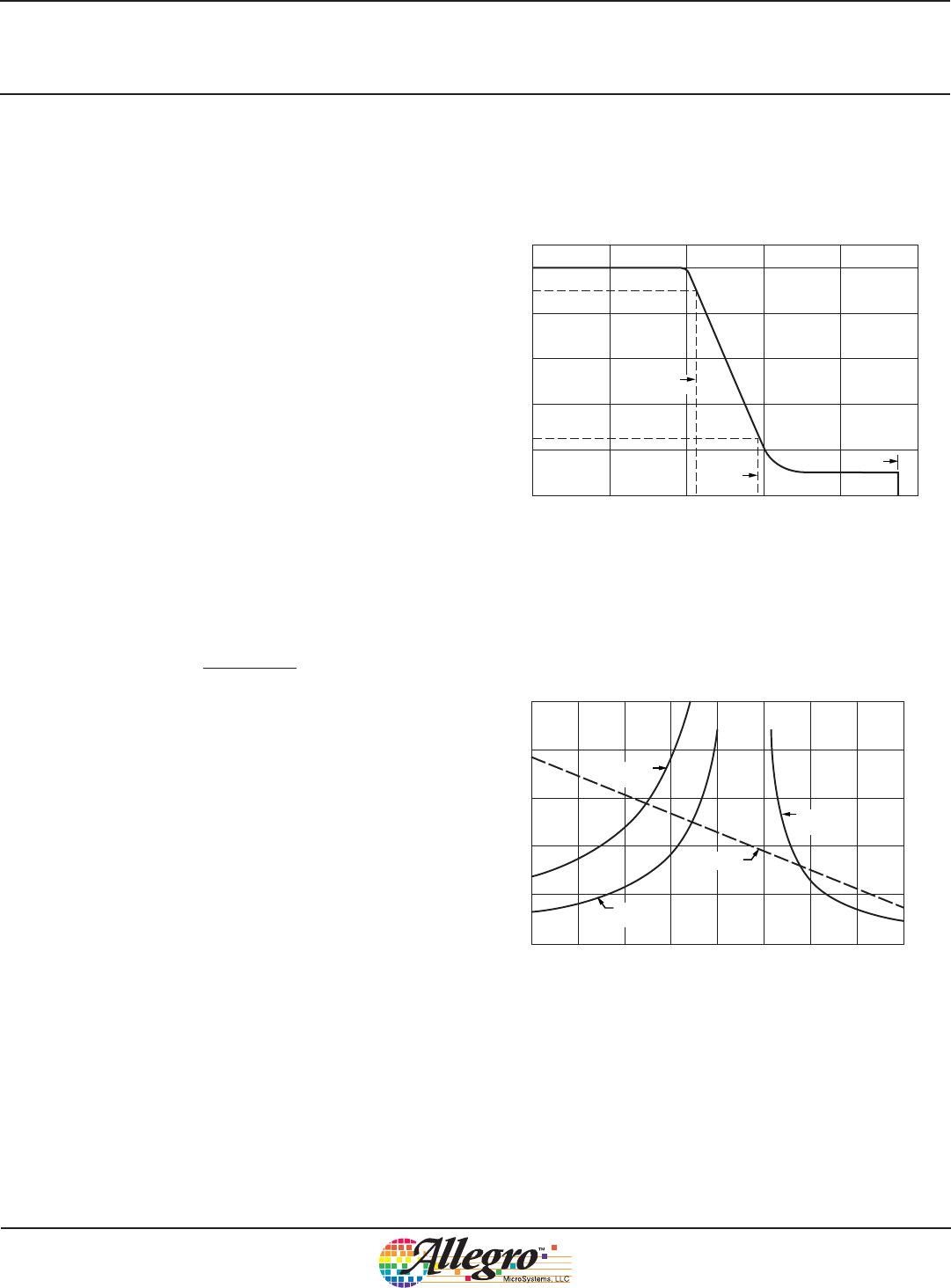

From these equations (and as illustrated in figure 5) it can be seen

that, if the power in the A6269 is not limited, then it will increase

as the supply voltage increases but the power in the LEDs will

remain constant.

Dissipation Limits

There are two features limiting the power that can be dissipated

by the A6269: thermal shutdown and thermal foldback.

Thermal Shutdown If the thermal foldback feature is disabled

by connecting the THTH pin to GND, or if the thermal resistance

from the A6269 to the ambient environment is high, then the

silicon temperature will rise to the thermal shutdown threshold

and the current will be disabled. After the current is disabled the

power dissipated will drop and the temperature will fall. When

the temperature falls by the hysteresis of the thermal shutdown

circuit, then the current will be re-enabled and the temperature

will start to rise again. This cycle will repeat continuously until

the ambient temperature drops or the A6269 is switched off. The

period of this thermal shutdown cycle will depend on several

electrical, mechanical, and thermal parameters, and could be from

a few milliseconds to a few seconds.

Thermal Foldback If there is a good thermal connection to the

A6269, then the thermal foldback feature will have time to act.

This will limit the silicon temperature by reducing the regulated

current and therefore the dissipation.

The thermal monitor will reduce the LED current as the tempera-

ture of the A6269 increases above the thermal monitor activation

temperature, T

JM

, as shown in figure 6. The figure shows the

operation of the A6269 with 2 strings of 3 red LEDs, each string

running at 100 mA. The forward voltage of each LED is 2.3 V and

the graph shows the current as the supply voltage increases from

14 to 17 V. As the supply voltage increases, without the thermal

foldback feature, the current would remain at 100 mA, as shown

by the dashed line. The solid line shows the resulting current

decrease as the thermal foldback feature acts.

If the thermal foldback feature did not affect LED current, the

current would increase the power dissipation and therefore the

silicon temperature. The thermal foldback feature reduces power

in the A6269 in order to limit the temperature increase, as shown

in figure 7. The figure shows the operation of the A6269 under

the same conditions as figure 6. That is, 2 strings of 3 red LEDs,

each string running at 100 mA with each LED forward voltage

Figure 5. Power Dissipation versus Supply Voltage

3.0

2.5

2.0

1.5

1.0

0.5

0

A6269 Power

Supply Voltage, V

IN

(V)

Power Dissipation, P

D

(W)

LED Power

2 Strings

V

LED

= 6.9 V

I

LED

= 100 mA

89 1110 1312 161514

Figure 6. LED current versus Supply Voltage

Figure 7. Junction Temperature versus Supply Voltage

54

52

50

48

46

44

42

40

Without thermal monitor

With thermal monitor

14.0 14.5 15.0 16.0 17.015.5

Supply Voltage, V

IN

(V)

I

LED

(mA)

16.5

2 Strings

V

LED

= 6.9 V

I

LED

= 100 mA

T

A

= 50°C

130

125

120

115

110

105

100

Without thermal monitor

With thermal monitor

14.0 14.5 15.0 16.0 17.015.5

Supply Voltage, V

IN

(V)

T

J

(°C)

16.5

2 Strings

V

LED

= 6.9 V

I

LED

= 100 mA

T

A

= 50°C