8

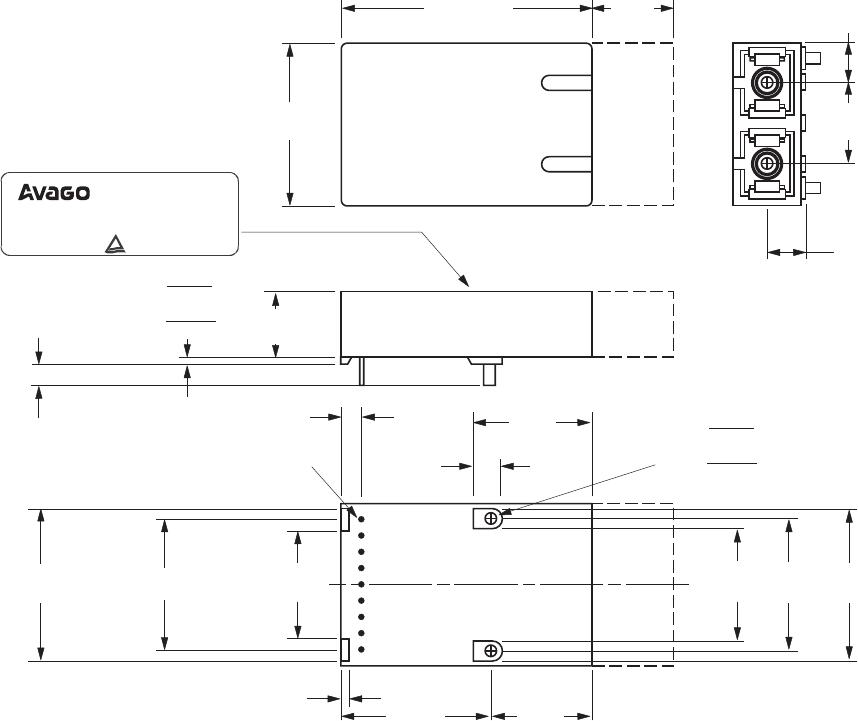

An un-shielded option, shown in Figure 7a is available for

the HFBR-5208xxxZ ber optic transceiver. This unit is

intended for applications where EMI is either not an issue

for the designer, or the unit resides in a highly-shielded

enclosure.

The rst shielded option, option EM, is for applications

where the position of the transceiver module will extend

outside the equipment enclosure. The metallized plastic

package and integral external metal shield of the trans-

ceiver helps locally to terminate EM elds to the chassis to

prevent their emissions outside the enclosure. This metal

shield contacts the panel or enclosure on the inside of

the aperture on all but the bottom side of the shield and

provides a good RF connection to the panel. This option

can accommodate various panel or enclosure thicknesses,

i.e. 1.02 mm (.04 in) min to 2.54 mm (0.1 in) max. The refer-

ence plane for this panel thickness variation is from the

front surface of the panel or enclosure. The recommended

length for pro truding the HFBR-5208EMZ transceiver

beyond the front surface of the panel or enclosure is

6.35 mm (0.25 in) . With this option, there is exibility of

positioning the module to t the speci c need of the en-

closure design. (See Figure 8 for the mechanical drawing

dimensions of this shield.)

The second shielded option, option FM, is for applications

that are designed to have a ush mounting of the module

with respect to the front of the panel or enclosure. The

ush-mount design accommodates a large variety of

panel thickness, i.e. 1.02 mm (.04 in) min to 2.54 mm (0.1

in) max. Note the reference plane for the ush-mount

design is the interior side of the panel or enclosure. The

recommended distance from the centerline of the trans-

ceiver front solder posts to the inside wall of the panel is

13.82 mm (0.544 in) . This option contacts the inside panel

or enclosure wall on all four sides of this metal shield.

(See Figure 10 for the mechanical drawing dimensions

of this shield.)

Both shielded design options connect only to the equip-

ment chassis and not to the signal or logic ground of the

circuit board within the equipment closure. The front

panel aperture dimensions are recommended in Figures

9 and 11. When layout of the printed circuit board is done

to incorporate these metal-shielded transceivers, keep

the area on the printed circuit board directly under the

external metal shield free of any components and circuit

board traces. For additional EMI performance advantage,

use duplex SC ber-optic connectors that have low metal

content inside the connector. This lowers the ability of the

metal ber-optic connectors to couple EMI out through

the aperture of the panel or enclosure.

Recommended Solder and Wash Process

The HFBR-5208xxxZ is compatible with industry-standard

wave or hand solder processes.

HFBR-5000 Process Plug

The HFBR-5208xxxZ transceiver is supplied with a process

plug, the HFBR-5000, for protection of the optical ports

with the Duplex SC connector receptacle. This process

plug prevents contamination during wave solder and

aqueous rinse as well as during handling, shipping or

storage. It is made of high-temperature, molded, sealing

material that will withstand +85°C and a rinse pressure

of 110 lb/in

2

.

Recommended Solder Fluxes and Cleaning/Degreasing

Chemicals

Solder uxes used with the HFBR-5208xxxZ ber-optic

transceiver should be water-soluble, organic solder uxes.

Some recommended solder uxes are Lonco 3355-11 from

London Chemical West, Inc. of Burbank, CA, and 100 Flux

from Alpha-metals of Jersey City, NJ

or equivalent uxes

from other companies.

Recommended cleaning and degreasing chemicals for

the HFBR-5208xxxZ are alcohols (methyl, isopropyl, iso-

butyl), aliphatics (hexane, heptane) and other chemicals,

such as soap solution or naphtha. Do not use partially

halogenated hydrocarbons for cleaning/degreasing.

Examples of chemicals to avoid are 1,1.1 trichloroethane,

ketones (such as MEK), acetone, chloroform, ethyl acetate,

methylene dichloride, phenol, methylene chloride or N

methylpyrolldone.

Regulatory Compliance

These transceiver products are intended to enable com-

mercial system designers to develop equipment that com-

plies with the various regulations governing certi cation

of Information Technology Equipment. See the Regulatory

Compliance Table for details. Additional information is

available from your Avago sales representative.