MP28265 – 5A, 21V, SYNCHRONOUS STEP-DOWN CONVERTER WITH INTERNAL MOSFETS

MP28265 Rev. 0.92 www.MonolithicPower.com 10

12/2/2009 MPS Proprietary Information. Unauthorized Photocopy and Duplication Prohibited.

© 2009 MPS. All Rights Reserved.

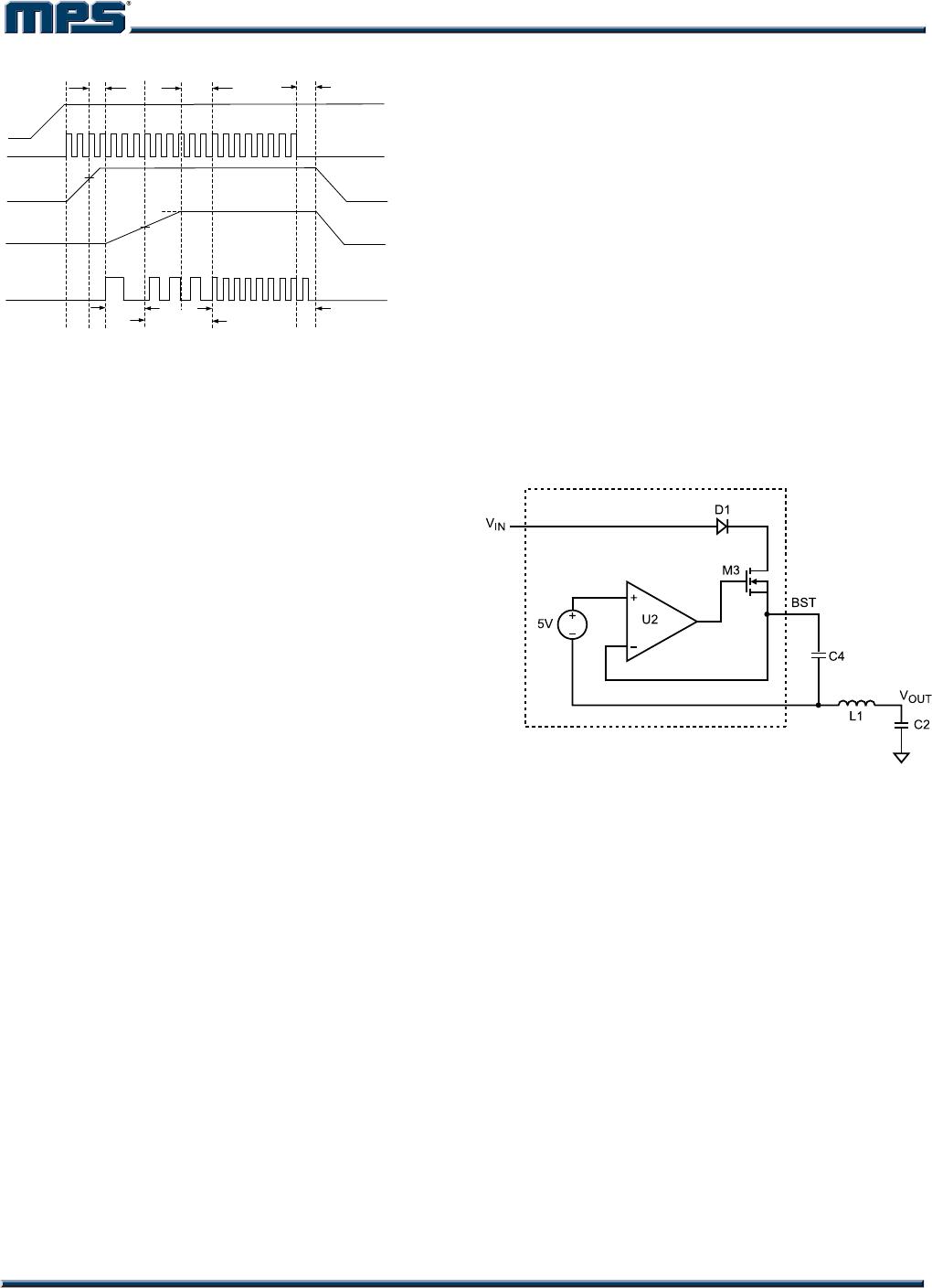

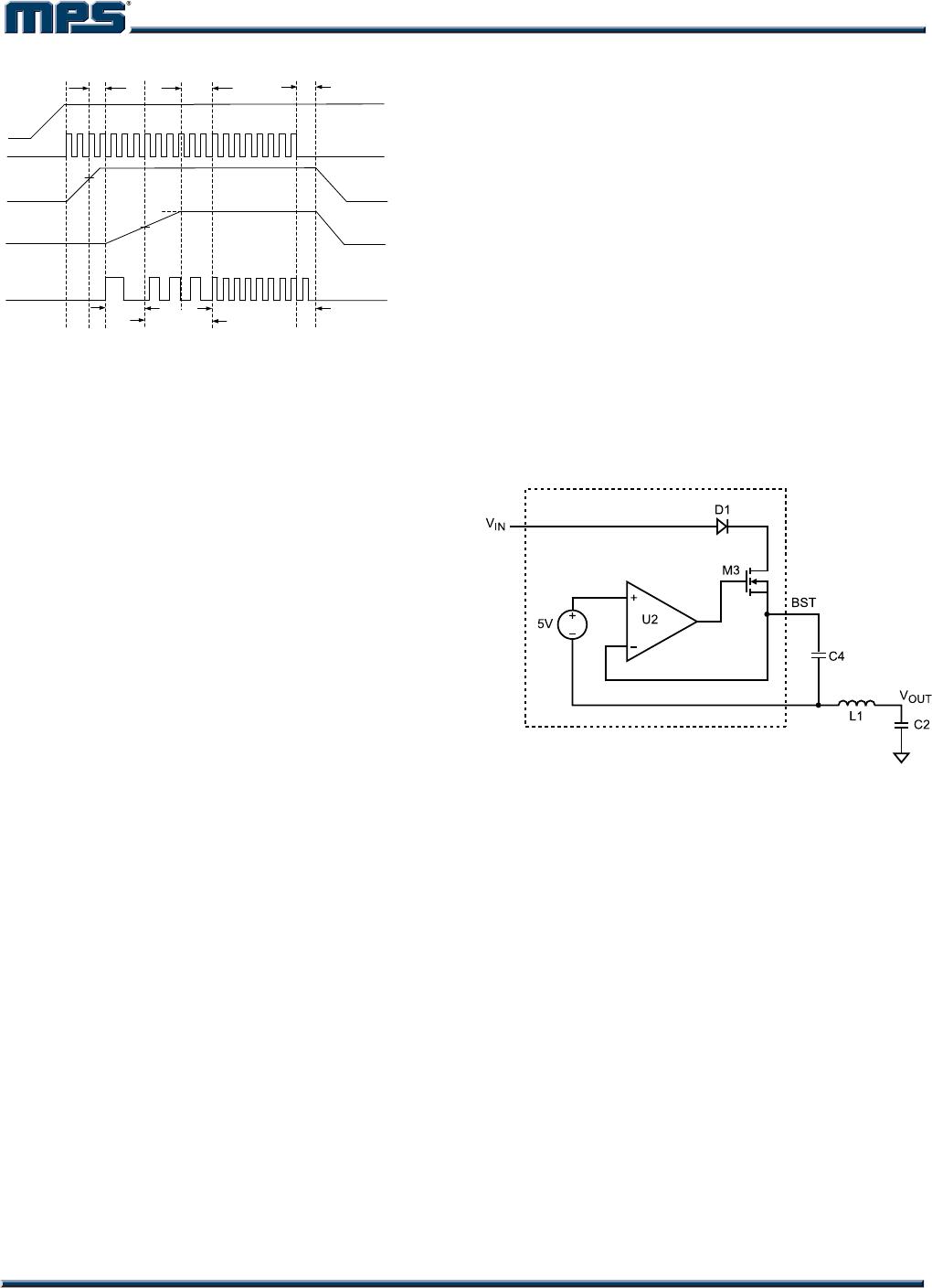

Vin

EN/Sync

Vcc

Vout

CLK

5us

Foldback

1.1MHz

External CLK

0.625*Vout_set

2ms1ms

V

CC_Rising

Vout_set

Figure 4—Startup Sequence Using External

Sync Clock Signal

Under-Voltage Lockout (UVLO)

Under-voltage lockout (UVLO) is implemented to

protect the chip from operating at insufficient

supply voltage. The MP28265 UVLO comparator

monitors the output voltage of the internal

regulator, VCC. The UVLO rising threshold is

about 4.0V while its falling threshold is a

consistent 3.2V.

Internal Soft-Start

The soft-start is implemented to prevent the

converter output voltage from overshooting

during startup. When the chip starts, the internal

circuitry generates a soft-start voltage (SS)

ramping up from 0V to 1.2V. When it is lower

than the internal reference (REF), SS overrides

REF so the error amplifier uses SS as the

reference. When SS is higher than REF, REF

regains control. The SS time is internally fixed to

4ms.

Over-Current-Protection and Hiccup

The MP28265 has cycle-by-cycle over current

limit when the inductor current peak value

exceeds the set current limit threshold.

Meanwhile, output voltage starts to drop until FB

is below the Under-Voltage (UV) threshold,

typically 30% below the reference. Once a UV is

triggered, the MP28265 enters hiccup mode to

periodically restart the part. This protection mode

is especially useful when the output is dead-short

to ground. The average short circuit current is

greatly reduced to alleviate the thermal issue and

to protect the regulator. The MP28265 exits the

hiccup mode once the over current condition is

removed.

Thermal Shutdown

Thermal shutdown is implemented to prevent the

chip from operating at exceedingly high

temperatures. When the silicon die temperature

is higher than 150°C, it shuts down the whole

chip. When the temperature is lower than its

lower threshold, typically 140°C, the chip is

enabled again.

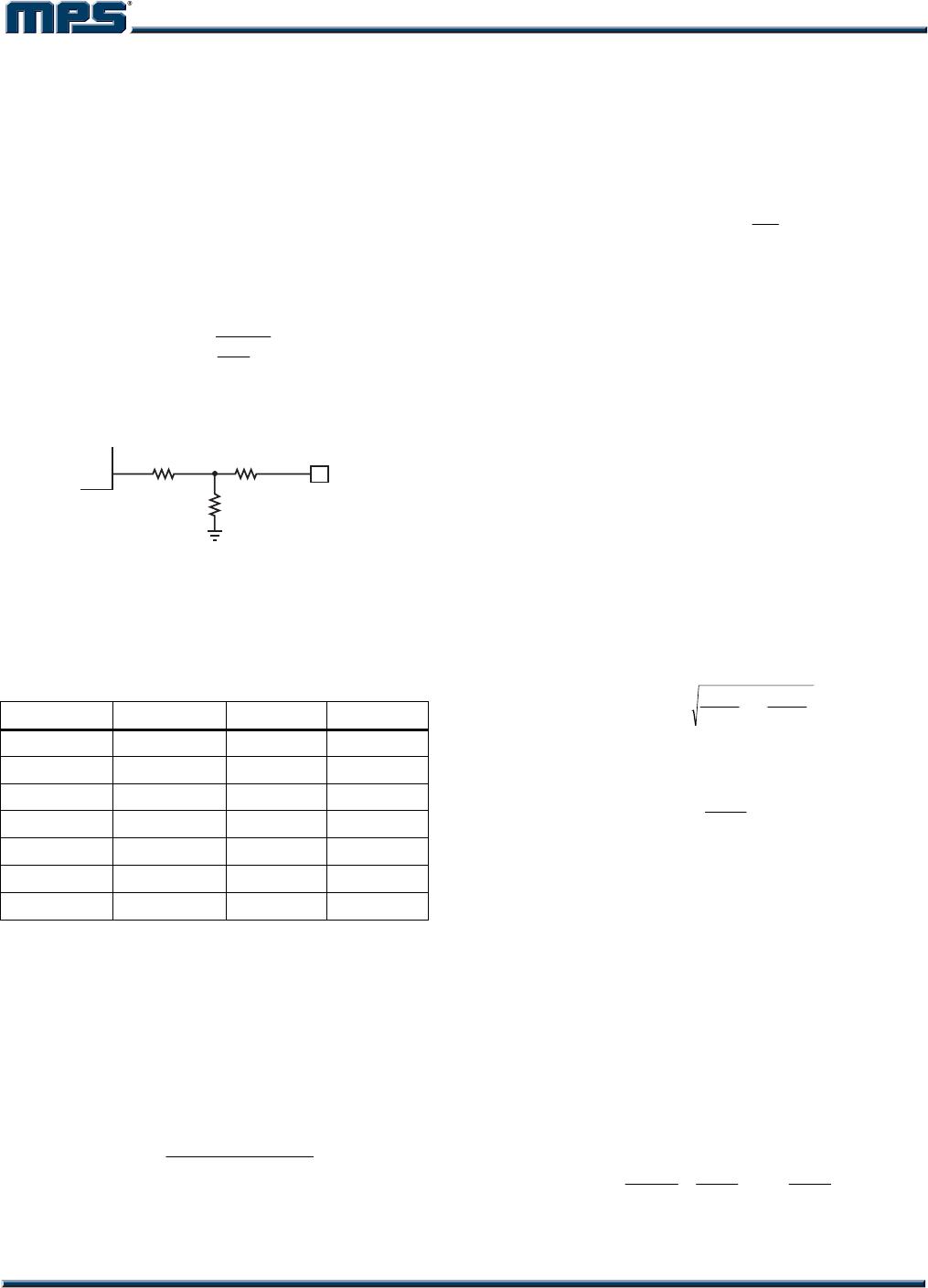

Floating Driver and Bootstrap Charging

The floating power MOSFET driver is powered by

an external bootstrap capacitor. This floating

driver has its own UVLO protection. This UVLO’s

rising threshold is 2.2V with a hysteresis of

150mV. The bootstrap capacitor voltage is

regulated internally by VIN through D1, M3, C4,

L1 and C2 (Figure 5). If (VIN-VSW) is more than

5V, U2 will regulate M3 to maintain a 5V BST

voltage across C4.

SW

Figure 5—Internal Bootstrap Charging Circuit

Startup and Shutdown

If both VIN and EN are higher than their

appropriate thresholds, the chip starts. The

reference block starts first, generating stable

reference voltage and currents, and then the

internal regulator is enabled. The regulator

provides stable supply for the remaining

circuitries.

Three events can shut down the chip: EN low,

VIN low and thermal shutdown. In the shutdown

procedure, the signaling path is first blocked to

avoid any fault triggering. The COMP voltage and

the internal supply rail are then pulled down. The

floating driver is not subject to this shutdown

command

.