Notes on Using Narrow pitch Connectors/High Current Connectors

–2–

ACCTB48E 201606-T

Regarding soldering

Handling Single Components

Precautions for mating

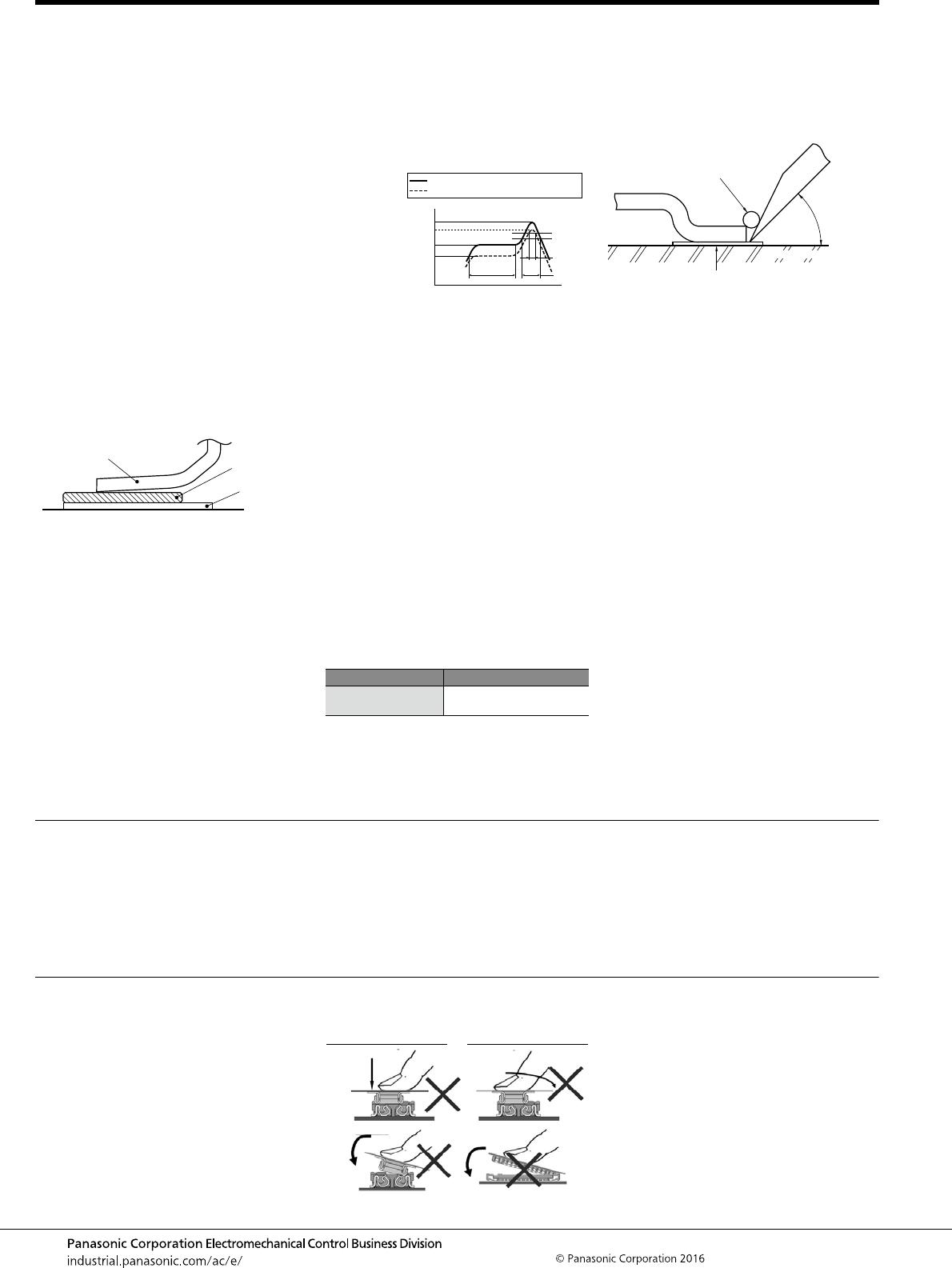

■ Reflow soldering

1) Measure the recommended profile

temperature for reflow soldering by

placing a sensor on the PC board near

the connector surface or terminals.

(Please refer to the specification for detail

because the temperature setting differs

by products.)

2) As for cream solder printing, screen

printing is recommended.

3) When setting the screen opening area

and PC board foot pattern area, refer the

recommended PC board pattern and

window size of metal mask on the

specification sheet, and make sure that

the size of board pattern and metal mask

at the base of the terminals are not

increased.

4) Please pay attentions not to provide

too much solder. It makes miss mating

because of interference at soldering

portion when mating.

5) When mounting on both sides of the

PC board and the connector is mounting

on the underside, use adhesives or other

means to ensure the connector is

properly fixed to the PC board. (Double

reflow soldering on the same side is

possible.)

6) The condition of solder or flux rise and

wettability varies depending on the type

of solder and flux. Solder and flux

characteristics should be taken into

consideration and also set the reflow

temperature and oxygen level.

7) Do not use resin-containing solder.

Otherwise, the contacts might be firmly

fixed.

8) Soldering conditions

Please use the reflow temperature profile

conditions recommended below for

reflow soldering. Please contact us

before using a temperature profile other

than that described below (e.g. lead-free

solder).

For products other than the ones above,

please refer to the latest product

specifications.

9) The temperature profiles given in this

catalog are values measured when using

the connector on a resin-based PC

board. When performed reflow soldering

on a metal board (iron, aluminum, etc.) or

a metal table to mount on a FPC, make

sure there is no deformation or

discoloration of the connector before

mounting.

10) Consult us when using a screen-

printing thickness other than that

recommended.

■ Hand soldering

1) Set the soldering iron so that the tip

temperature is less than that given in the

table below.

Table A

2) Do not allow flux to spread onto the

connector leads or PC board. This may

lead to flux rising up to the connector

inside.

3) Touch the soldering iron to the foot

pattern. After the foot pattern and

connector terminal are heated, apply the

solder wire so it melts at the end of the

connector terminals.

4) Be aware that soldering while applying

a load on the connector terminals may

cause improper operation of the

connector.

5) Thoroughly clean the soldering iron.

6) Flux from the solder wire may get on

the contact surfaces during soldering

operations. After soldering, carefully

check the contact surfaces and clean off

any solder before use.

7) These connector is low profile type. If

too much solder is supplied for hand

soldering, It makes miss mating because

of interference at soldering portion.

Please pay attentions.

■ Solder reworking

1) Finish reworking in one operation.

2) In case of soldering rework of bridges.

Don’t use supplementary solder flux.

Doing so may cause contact problems by

flux.

3) Keep the soldering iron tip temperature

below the temperature given in Table A.

Terminal

Paste

solder

PC board

foot pattern

Product name Soldering iron temperature

SMD type connectors

300°C within 5 sec.

350°C within 3 sec.

60 to 120 sec.

Preheating

Peak temperature

200°C

220°C

Upper limited (Solder heat resistance)

Peak temperature 260°C

230°C

180°C

150°C

70 sec.

25 sec.

Lower limited (Solder wettability)

Time

Temperature

Apply the solder

wire here

Terminal

Pattern

PC board

Small angle as

possible up to

45 degrees

Soldering

iron

1) Make sure not to drop or allow parts to

fall from work bench.

2) Excessive force applied to the

terminals could cause warping, come

out, or weaken the adhesive strength of

the solder. Handle with care.

3) Do not insert or remove the connector

when it is not soldered. Forcibly applied

external pressure on the terminals can

weaken the adherence of the terminals to

the molded part or cause the terminals to

lose their evenness.

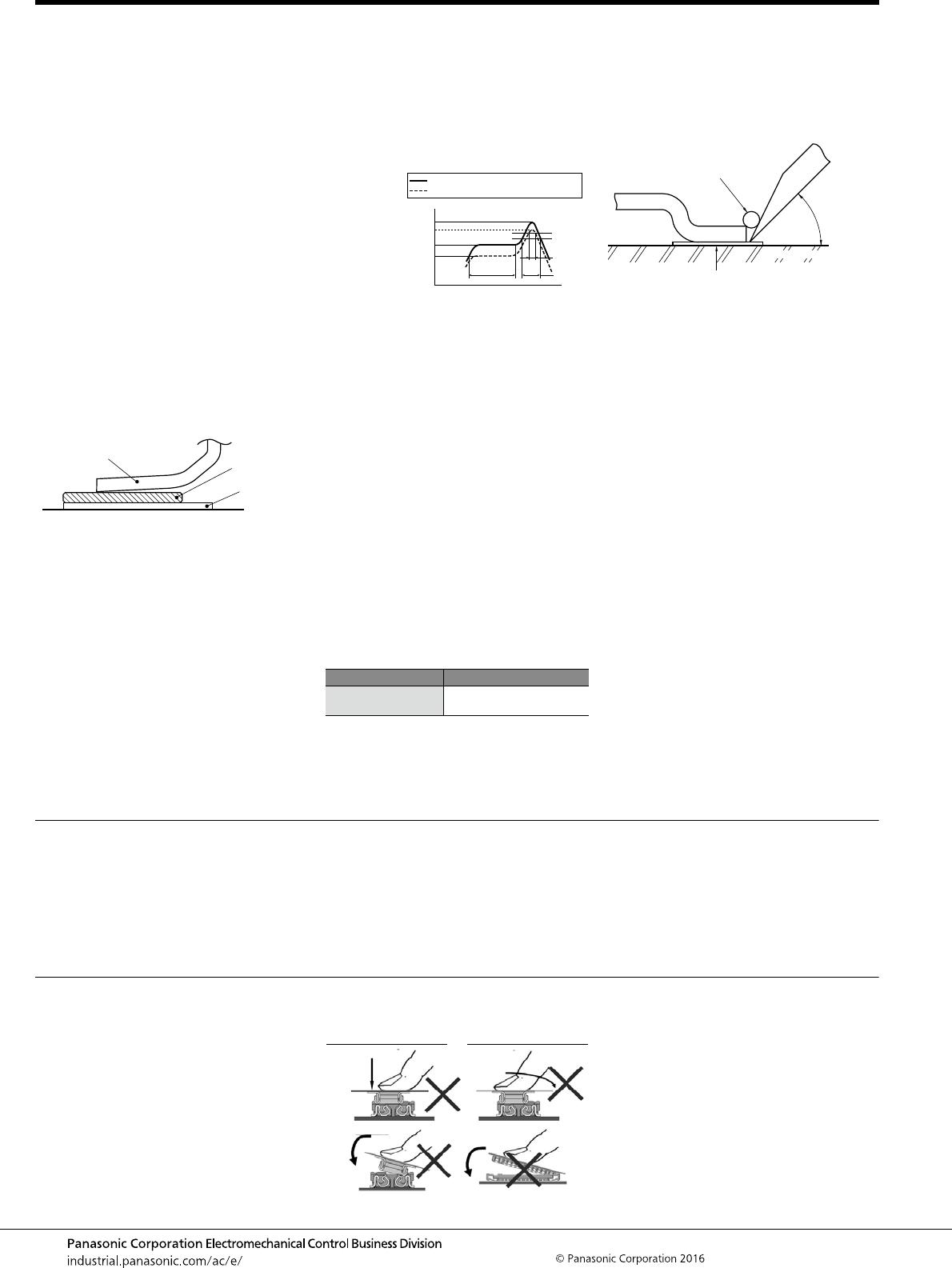

This product is designed with ease of

handling. However, in order to prevent the

deformation or damage of contacts and

molding, take care and do not mate the

connectors as shown right.

Strongly pressed and twisted

Tilted mating

Press-fitting while the mating

inlets of the socket and

header are not matched.