LTC3559/LTC3559-1

18

3559fb

APPLICATIONS INFORMATION

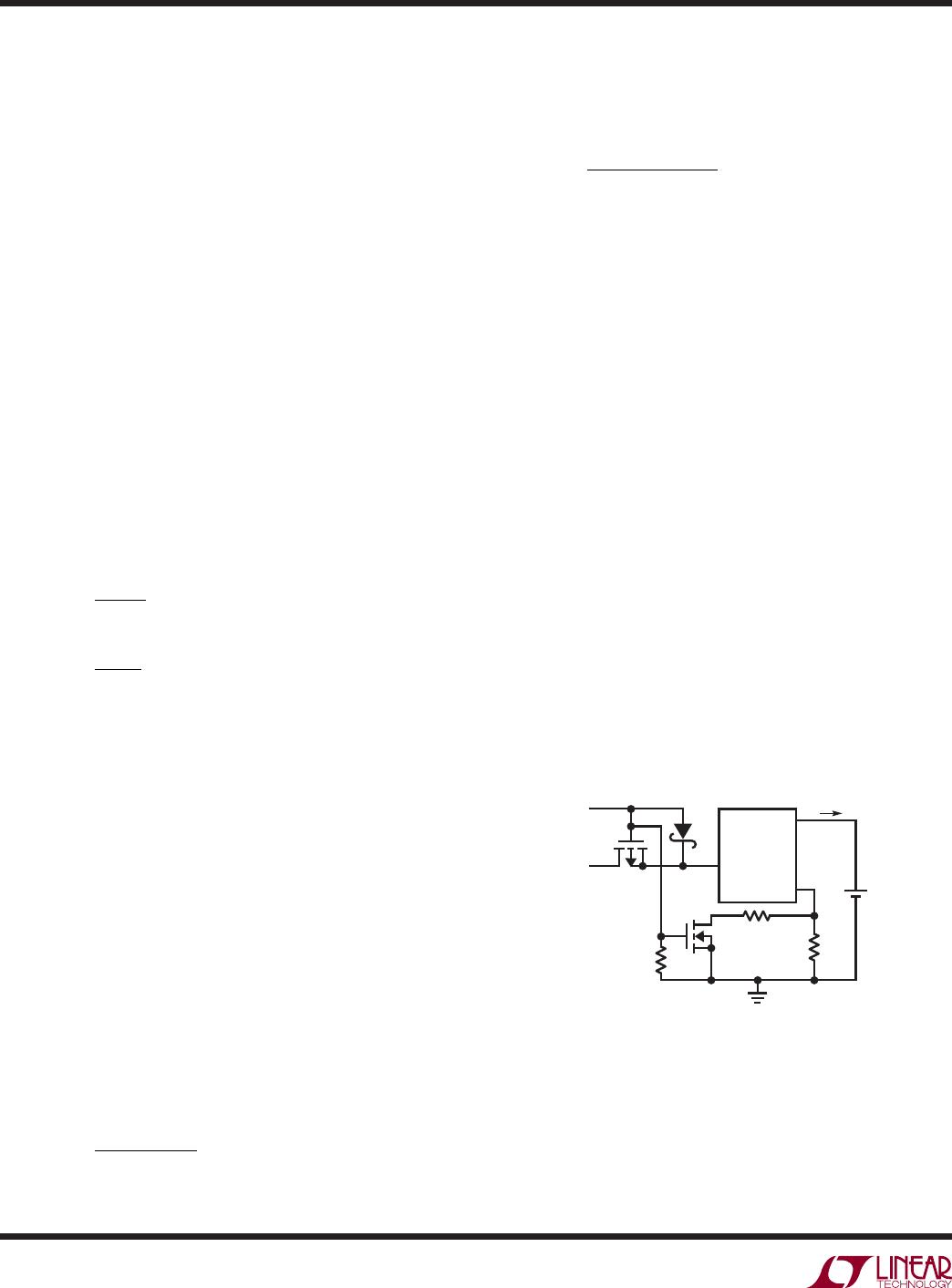

Average, rather than instantaneous, battery current may be

of interest to the user. For example, if a switching power

supply operating in low-current mode is connected in

parallel with the battery, the average current being pulled

out of the BAT pin is typically of more interest than the

instantaneous current pulses. In such a case, a simple RC

fi lter can be used on the PROG pin to measure the average

battery current as shown in Figure 6. A 10k resistor has

been added between the PROG pin and the fi lter capacitor

to ensure stability.

the current from building up in the cable too fast thus

dampening out any resonant overshoot.

Buck Switching Regulator General Information

The LTC3559/LTC3559-1 contain two 2.25MHz constant-

frequency current mode switching regulators that provide

up to 400mA each. Both switchers can be programmed

for a minimum output voltage of 0.8V and can be used

to power a microcontroller core, microcontroller I/O,

memory or other logic circuitry. Both regulators support

100% duty cycle operation (dropout mode) when the

input voltage drops very close to the output voltage and

are also capable of operating in Burst Mode operation for

highest effi ciencies at light loads (Burst Mode operation

is pin selectable). The switching regulators also include

soft-start to limit inrush current when powering on, short

circuit current protection, and switch node slew limiting

circuitry to reduce radiated EMI.

A single MODE pin sets both regulators in Burst Mode

operation or pulse skip operating mode while each regula-

tor is enabled individually through their respective enable

pins EN1 and EN2. The buck regulators input supply (PV

IN

)

should be connected to the battery pin (BAT). This allows

the undervoltage lockout circuit on the BAT pin to disable

the buck regulators when the BAT voltage drops below

2.45V. Do not drive the buck switching regulators from

a voltage other than BAT. A 2.2μF decoupling capacitor

from the PV

IN

pin to GND is recommended.

Buck Switching Regulator

Output Voltage Programming

Both switching regulators can be programmed for output

voltages greater than 0.8V. The output voltage for each

buck switching regulator is programmed using a resistor

divider from the switching regulator output connected to

the feedback pins (FB1 and FB2) such that:

V

OUT

= 0.8(1 + R1/R2)

Typical values for R1 are in the range of 40k to 1M. The

capacitor C

FB

cancels the pole created by feedback re-

sistors and the input capacitance of the FB pin and also

helps to improve transient response for output voltages

much greater than 0.8V. A variety of capacitor sizes can

be used for C

FB

but a value of 10pF is recommended for

3559 F06

C

FILTER

CHARGE

CURRENT

MONITOR

CIRCUITRY

R

PROG

LTC3559/

LTC3559-1

PROG

GND

10k

Figure 6. Isolated Capacitive Load on PROG Pin and Filtering

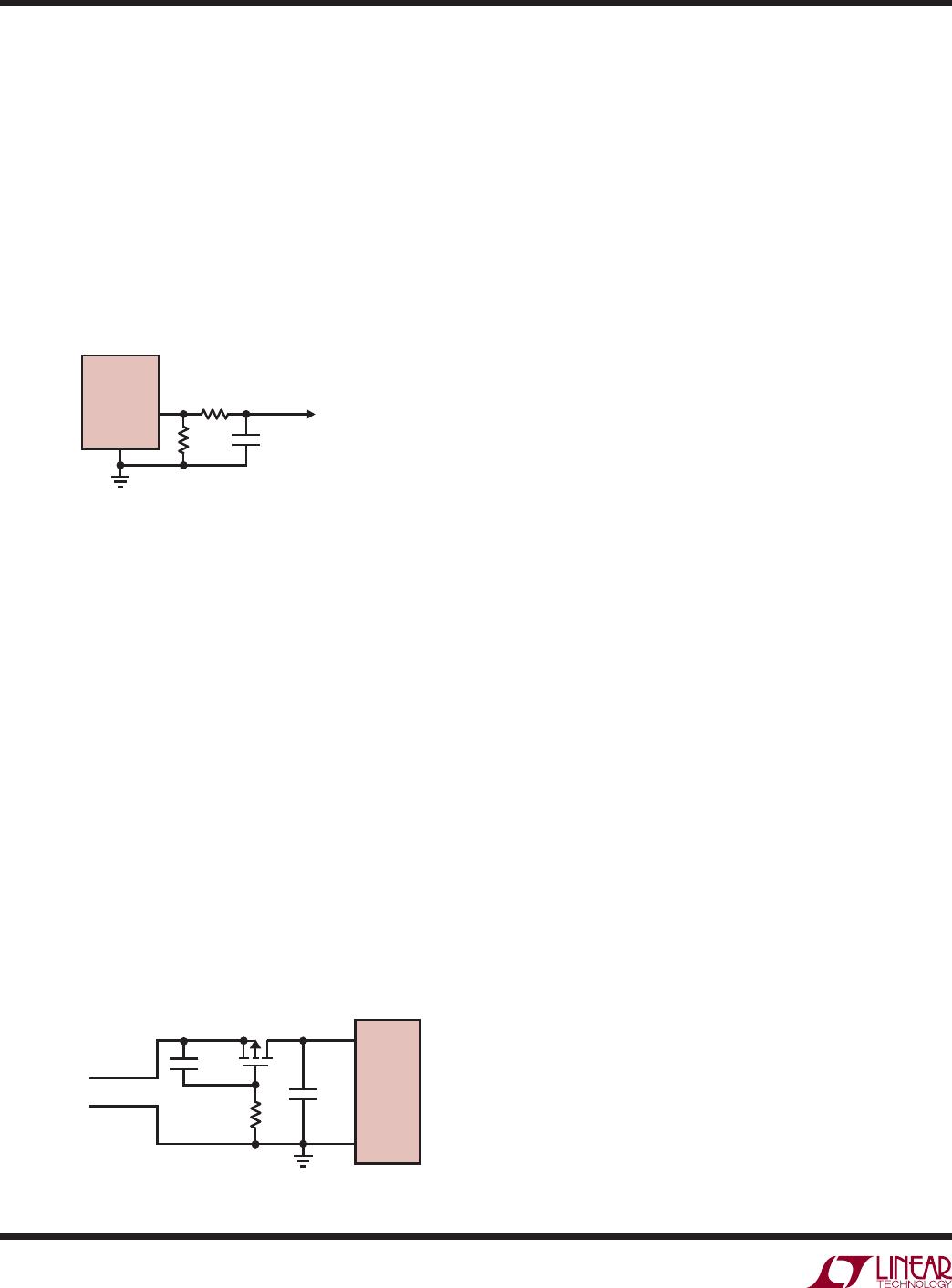

USB Inrush Limiting

When a USB cable is plugged into a portable product,

the inductance of the cable and the high-Q ceramic input

capacitor form an L-C resonant circuit. If there is not

much impedance in the cable, it is possible for the voltage

at the input of the product to reach as high as twice the

USB voltage (~10V) before it settles out. In fact, due to

the high voltage coeffi cient of many ceramic capacitors

(a nonlinearity), the voltage may even exceed twice the

USB voltage. To prevent excessive voltage from damaging

the LTC3559/LTC3559-1 during a hot insertion, the soft

connect circuit in Figure 7 can be employed.

In the circuit of Figure 7, capacitor C1 holds MP1 off when

the cable is fi rst connected. Eventually C1 begins to charge

up to the USB voltage applying increasing gate support

to MP1. The long time constant of R1 and C1 prevents

Figure 7. USB Soft Connect Circuit

R1

40k

5V USB

INPUT

3559 F07

C1

100nF

C2

10μF

MP1

Si2333

USB CABLE

V

CC

GND

LTC3559/

LTC3559-1