Spec No. JELF243B-0019K-01 P.8/9

MURATA MFG.CO., LTD

Reference

Only

11.5 Solder Volume

・Solder shall be used not to be exceeded the upper limits as shown below.

・Accordingly increasing the solder volume, the mechanical stress to Chip is also increased.

Exceeding solder volume may cause the failure of mechanical or electrical performance.

1/3T≦t≦T

T: thickness of electrode

11.6 Product’s location

The following shall be considered when designing and laying out P.C.B.'s.

(1) P.C.B. shall be designed so that products are not subject to the mechanical stress due to warping the board.

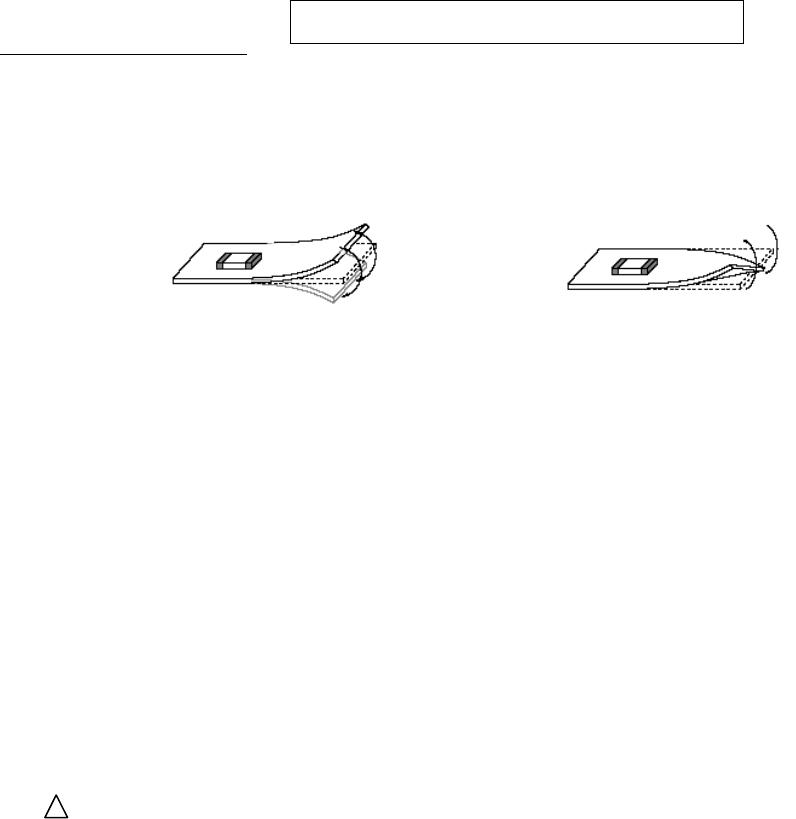

[Products direction]

Products shall be located in the sideways

direction (Length: a‹b) to the mechanical

stress.

(2) Products location on P.C.B. separation

Products (A, B, C, D) shall be located carefully so

that products are not subject to the mechanical

stress due to warping the board.

Because they may be subjected the mechanical

stress in order of ACBD.

11.7 Cleaning Conditions

Products shall be cleaned on the following conditions.

(1) Cleaning temperature shall be limited to 60°C max. (40°C max for IPA.)

(2) Ultrasonic cleaning shall comply with the following conditions with avoiding the resonance

phenomenon at the mounted products and P.C.B.

Power : 20 W / l max. Frequency : 28kHz to 40kHz Time : 5 min max.

(3) Cleaner

1. Alcohol type cleaner

Isopropyl alcohol (IPA)

2. Aqueous agent

PINE ALPHA ST-100S

(4) There shall be no residual flux and residual cleaner after cleaning. In the case of using aqueous agent,

products shall be dried completely after rinse with de-ionized water in order to remove the cleaner.

(5) Other cleaning Please contact us.

11.8 Resin coating

The inductance value may change and/or it may affect on the product's performance due to high

cure-stress of resin to be used for coating/molding products. So please pay your careful attention when you

select resin.

In prior to use, please make the reliability evaluation with the product mounted in your application set.

11.9 Caution for use

There is possibility that the inductance value change due to magnetism. Don‘t use a magnet or a pair of

tweezers with magnetism when chip coil are handled. (The tip of the tweezers should be molded with resin or

pottery.)

11.10 Magnetic Saturation

When the excessive current over rated current is applied, the inductance value may change due to

magnetism.

Seam

Slit

A

D

B

C

b

a

Length:a‹b

〈

Poor example

〉

〈

Good example

〉

b

a

Upper Limit

Recommendable

t