SpecNo.JELF243B-9118B-01 P.8 / 11

MURATA MFG.CO., LTD

Reference

Onl

8.3 Limitation of Applications

Please contact us before using our products for the applications listed below which require especially high

reliability for the prevention of defects which might directly cause damage to the third party's life, body or

property.

(1) Aircraft equipment (6) Transportation equipment (trains, ships, etc.)

(2) Aerospace equipment

(7) Traffic signal equipment

(3) Undersea equipment

(8) Disaster prevention / crime prevention equipment

(4) Power plant control equipment

(9) Data-processing equipment

(5) Medical equipment

(10) Applications of similar complexity and /or reliability

requirements to the applications listed in the above

9. Notice

Products can only be soldered with reflow.

This product is designed for solder mounting.

Please consult us in advance for applying other mounting method such as conductive adhesive.

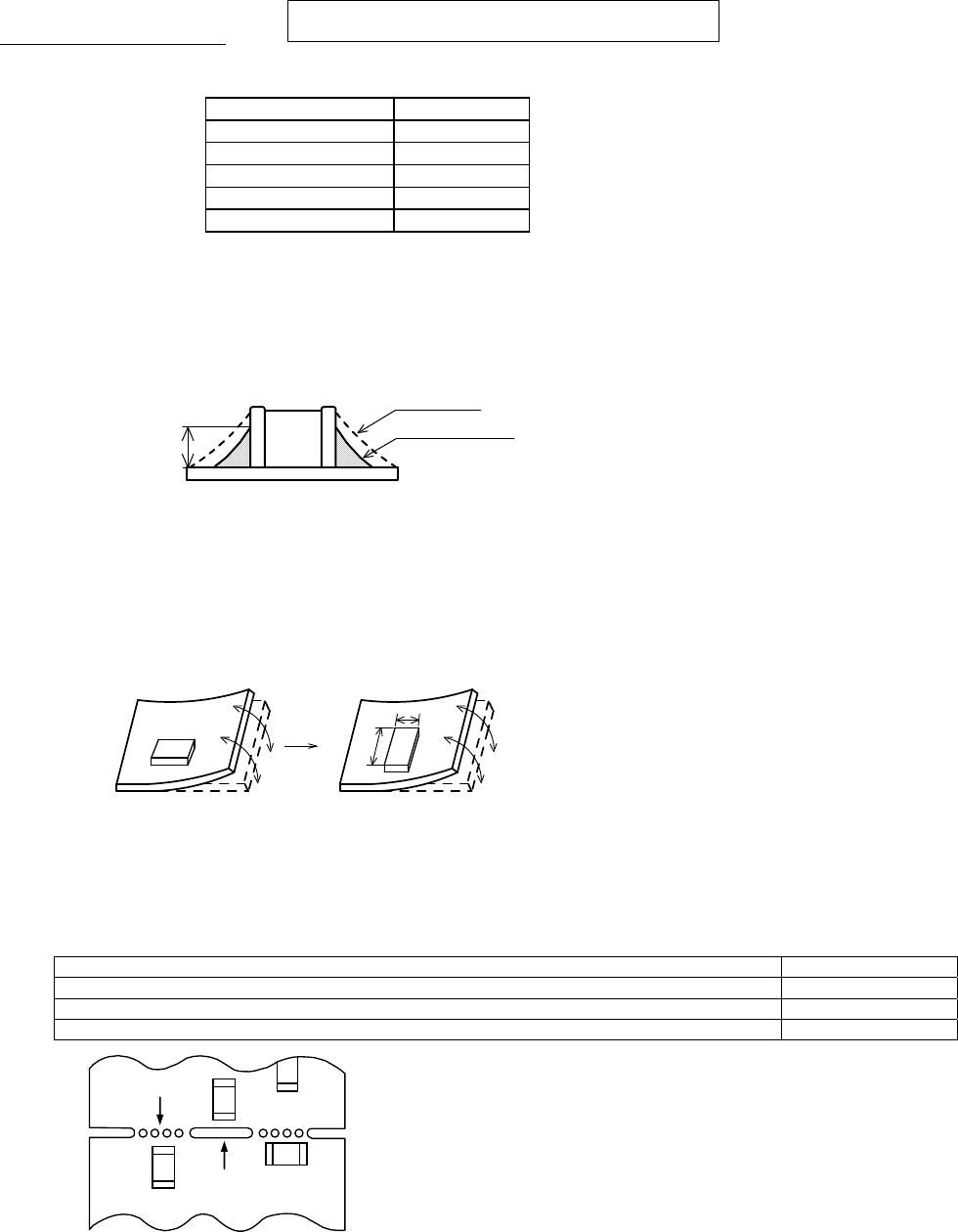

9.1 Land pattern designing

a 0.5

b 1.2

c 0.65

(in mm)

9.2 Flux, Solder

・Use rosin-based flux.

Don’t use highly acidic flux with halide content exceeding 0.2(wt)% (chlorine conversion value).

Don’t use water-soluble flux.

・Use Sn-3.0Ag-0.5Cu solder.

・Standard thickness of solder paste : 100μm to 150μm.

9.3 Reflow soldering conditions

・Inductance value may be changed a little due to the amount of solder.

So, the chip coil shall be soldered by reflow so that the solder volume can be controlled.

・Pre-heating should be in such a way that the temperature difference between solder and

product surface is limited to 150°C max. Cooling into solvent after soldering also should be in

such a way that the temperature difference is limited to 100°C max.

Insufficient pre-heating may cause cracks on the product, resulting in the deterioration of products quality.

・Standard soldering profile and the limit soldering profile is as follows.

The excessive limit soldering conditions may cause leaching of the electrode and / or resulting

in the deterioration of product quality.

・Reflow soldering profile

Standard Profile Limit Profile

Pre-heating 150°C~180°C 、90s±30s

Heating above 220°C、30s~60s above 230°C、60s max.

Peak temperature 245°C±3°C 260°C,10s

Cycle of reflow 2 times 2 times

a

b

Chip Coil

Land

Solder Resist

c

Limit Profile

Standard Profile

90s±30s

230℃

260℃

245℃±3℃

220℃

30s~60s

60s max.

180

150

Temp.

(s)

(℃)

Time.