341

©2008 Littelfuse, Inc.

Revised: July 9, 2008

Teccor

®

brand Thyristors

Specifications are subject to change without notice.

Please refer to http://www.littelfuse.com for current information.

341

©2008 Littelfuse, Inc.

Teccor

®

brand Thyristors

Specifications are subject to change without notice.

Please refer to http://www.littelfuse.com for current information.

HTxxx & HTMxxx & STxxx Series

Standard Bidirectional DIAC Trigger

DIACs

Physical Specifications

Terminal Finish

100% Matte-Tin Plated/ Pb-Free Solder

Dipped

Body Material

DO-214: UL recognized epoxy meeting

flammabilty classification 94V-0.

DO-35/MINIMELF: Glass case body

Lead Material

DO-214: Copper Alloy

DO-35/MINIMELF: Copper Clad Iron

Reliability/Environmental Tests

Test

Specifications and Conditions

High Temperature

Voltage Blocking

MIL-STD-750, M-1040, Cond A Applied

80% of Rated Min V

BO

(VAC-peak) @

125°C for 1008 hours

Temperature Cycling

MIL-STD-750, M-1051,

100 cycles; -40°C to +150°C;

15-min dwell-time

Temperature/

Humidity

EIA / JEDEC, JESD22-A101

1008 hours; 80% of Rated Min V

BO

(V

DC

):

85°C; 85%

rel humidity

High Temp Storage MIL-STD-750, M-1031,1008 hours; 150°C

Low-Temp Storage 1008 hours; -40°C

Thermal Shock

MIL-STD-750, M-1056

10 cycles; 0°C to 100°C; 5-min dwell

time at each temperature; 10 sec (max)

transfer time between temperature

Autoclave

EIA / JEDEC, JESD22-A102 168 hours

(121°C at 2 ATMs) and 100% R/H

Resistance to

Solder Heat

MIL-STD-750 Method 2031

Solderability ANSI/J-STD-002, category 3, Test A

Lead Bend

MIL-STD-750, M-2036 Cond E

Burn-in 1 firing per 1/2 cycle, 168 hours

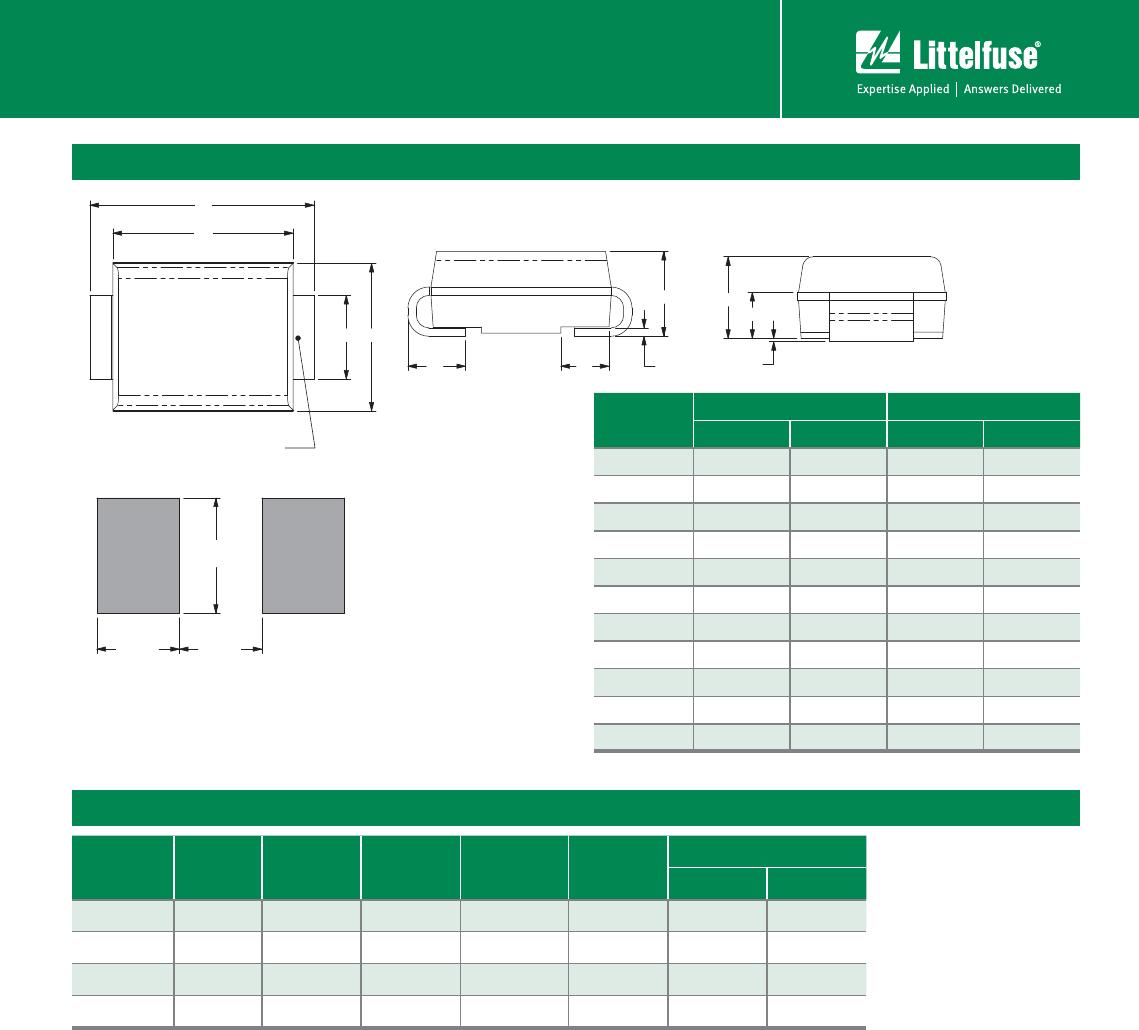

Dimensions – MINIMELF / SOD-80 (MM Package)

A

C

C

D

B

.002 E-F

E

F

Dimensions

Inches Millimeters

Min Typ Max Min Typ Max

A 0.125 0.134 0.142 3.18 3.40 3.61

B 0.066 0.068 0.070 1.68 1.73 1.78

C 0.012 0.018 0.020 0.30 0.46 0.51

D — 0.063 — — 1.60 —

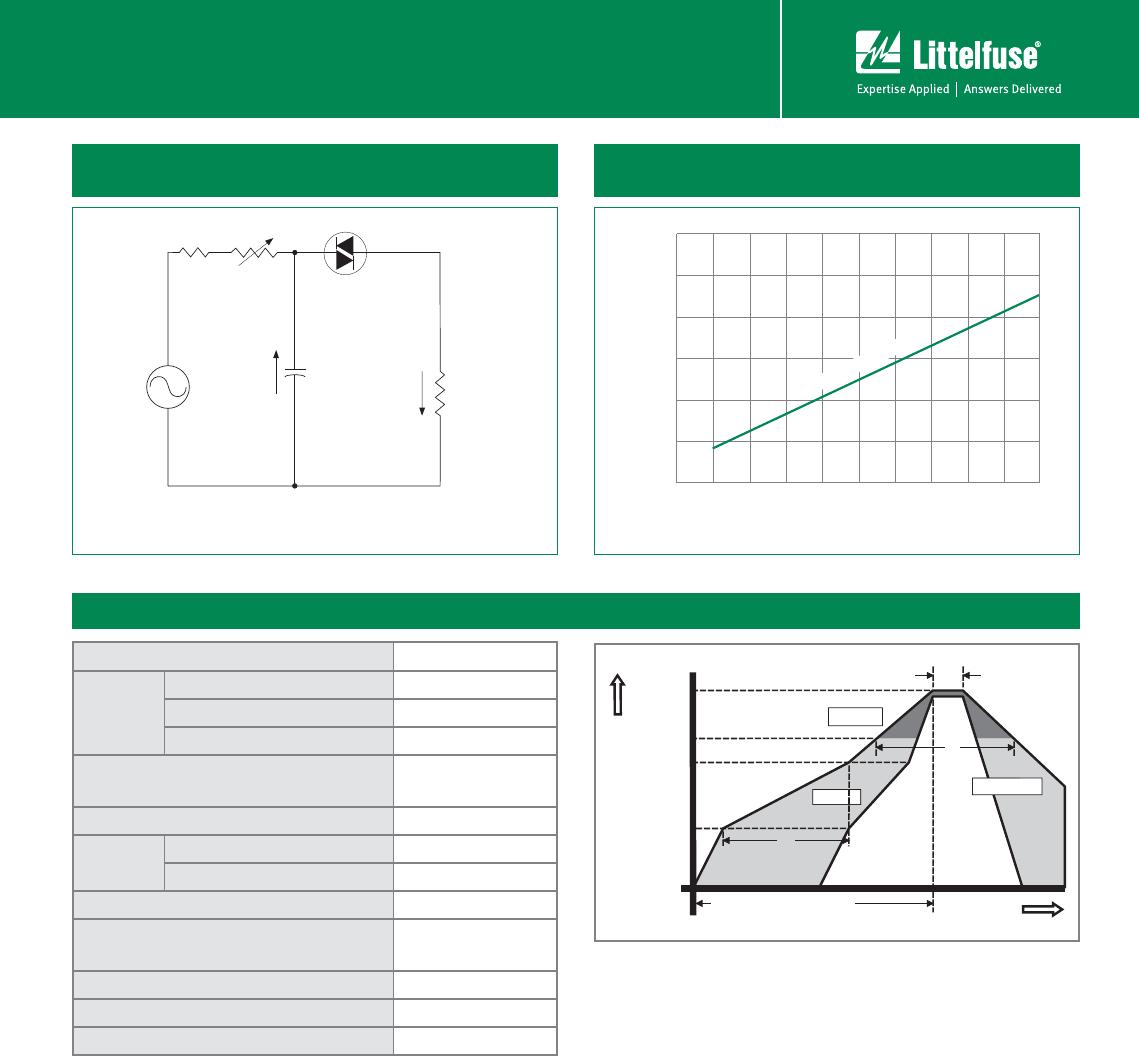

Design Considerations

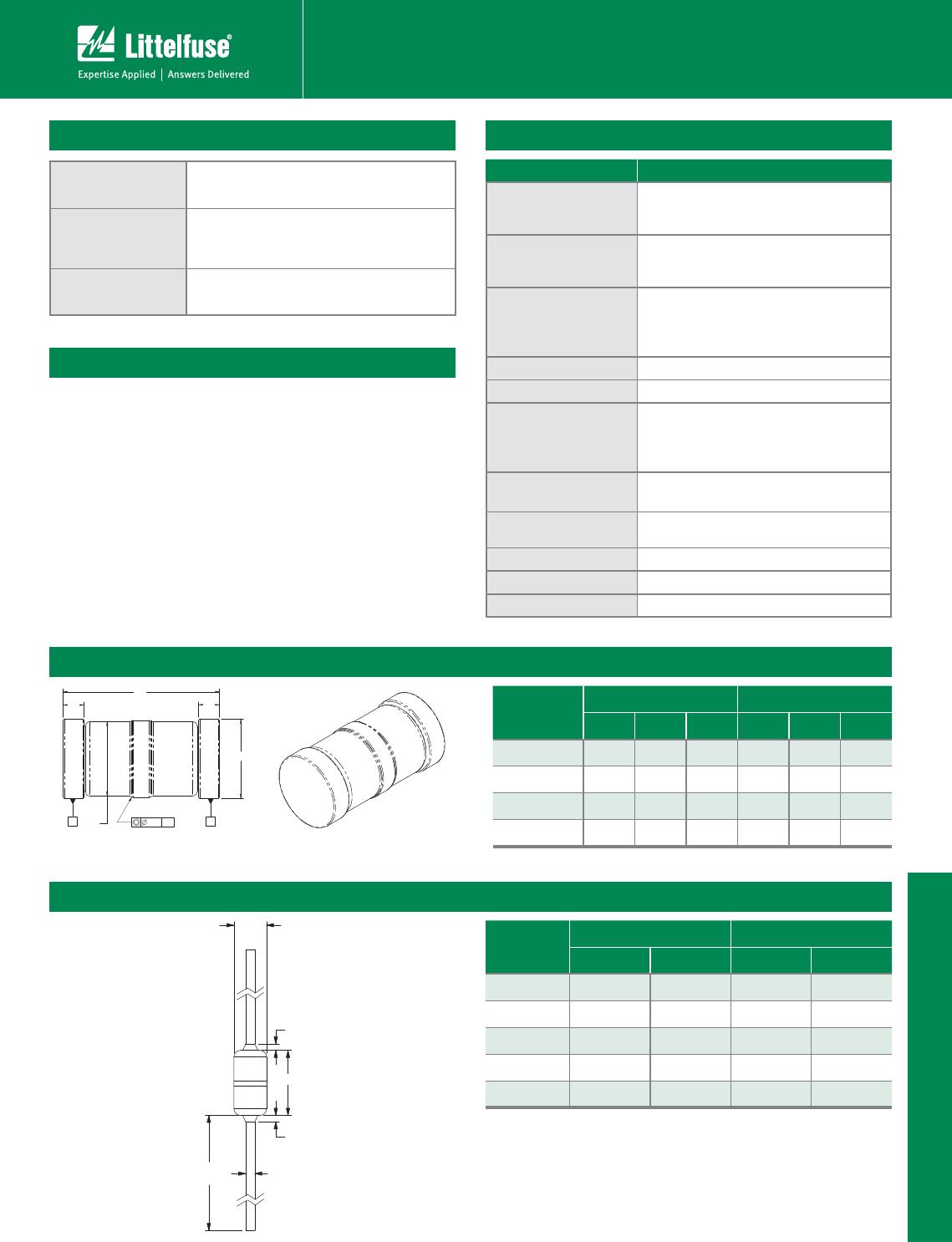

Dimensions – DO-35 (Y Package)

C

B

B

A

E

TYP.

D (TYP.)

Dimension

Inches Millimeters

Min Max Min Max

A (Note 1) 0.060 0.090 1.530 2.280

B

(Note 2) 0.015 0.381

C

(Note 1) 0.135 0.165 3.430 4.190

D 0.018 0.022 0.458 0.558

E 1.000 25.400

Notes:

1. Package contour optional within dimensions A and C. Slugs, if any, shall be included

within this cylinger but shall not be subject to

the minimum limit of Dimention A.

2. Lead diameter is not controlled in this zone to allow for flash, lead finish build-up and

minor irregularities other than slugs.

Careful selection of the correct device for the application’s

operating parameters and environment will go a long

way toward extending the operating life of the Thyristor.

Overheating and surge currents are the main killers of

DIACs. Correct mounting, soldering, and forming of the

leads also help protect against component damage.