4/9 No.EE21-KHDC000-02

KYOCERA CORPORATION

6. Requirement and measurement method

No Contents Requirement Measurement method and conditions

1

Appearance

No serious defect.

Microscope (10 magnifications).

2

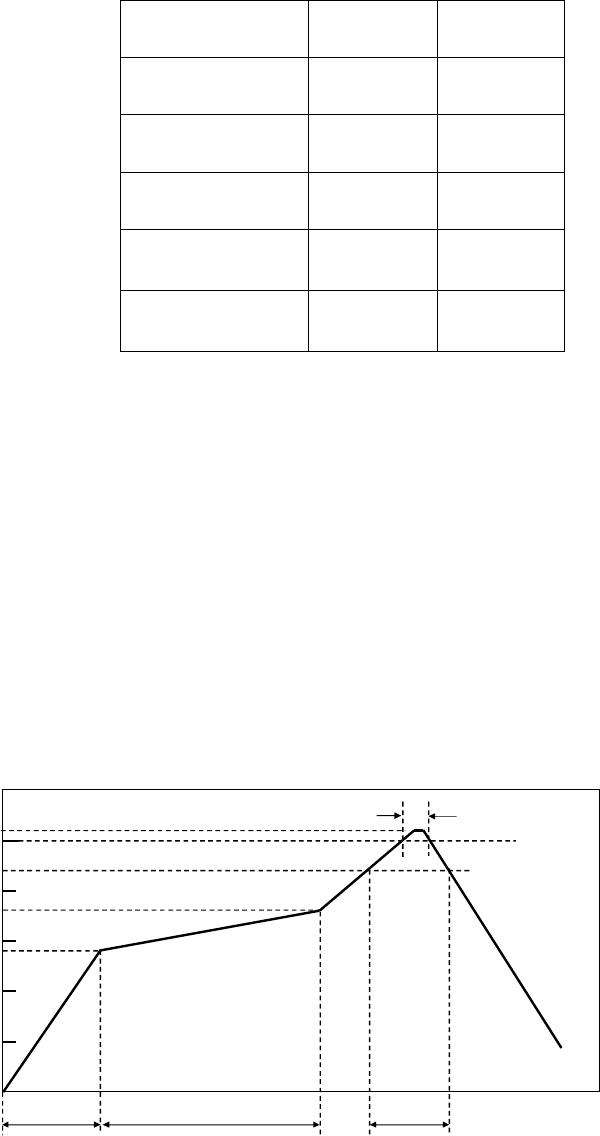

Dimensions

Figure – 1

Digital caliper and measurement

microscope.

Measured by HP4278A.

Capaci

-tance

Measured

frequency

voltage

22pF to

470pF

1MHz

+- 10kHz

47nF to

10uF

1kHz

+-10Hz

1V+- 0.2V

rms

3

Capacitance

3 – 2 item

4

Insulation

resistance

3 – 1 item

Measured by super meg ohmmeter

model SM – 9E (made by TOA).

1-3 or 2-3 (at figure – 1) measured.

To measure after charging with the rated

voltage for 1 minute at room temperature

and normal humidity.

5

Dielectric

strength

No problem observed.

To charge between 1 ( or 3 ) and 2 (at

figure – 1) with the 2.5 times high of the

rated voltage for 1 to 5 seconds.

6

Current

resistance

No problem observed.

Print rated current for 1 to 5 seconds

between 1-2 (at figure – 1).

7

Solderability

Coverage Min. 90 %

Each termination.

Completely coat parts with flux and

propanol solution and preheat for 1

minute at 120 to 150deg.. Afterwards, dip

parts into solder bath for 2+-0.5 seconds

at 230+-5deg..

Solder level checked by naked eye under

microscope.