Panasonic Corporation 2013©

Panasonic Corporation Automation Controls Buisiness Division

industrial.panasonic.com/ac/e/

Notes on Using Narrow pitch Connectors

–

9–

ACCTB48E 201303-T

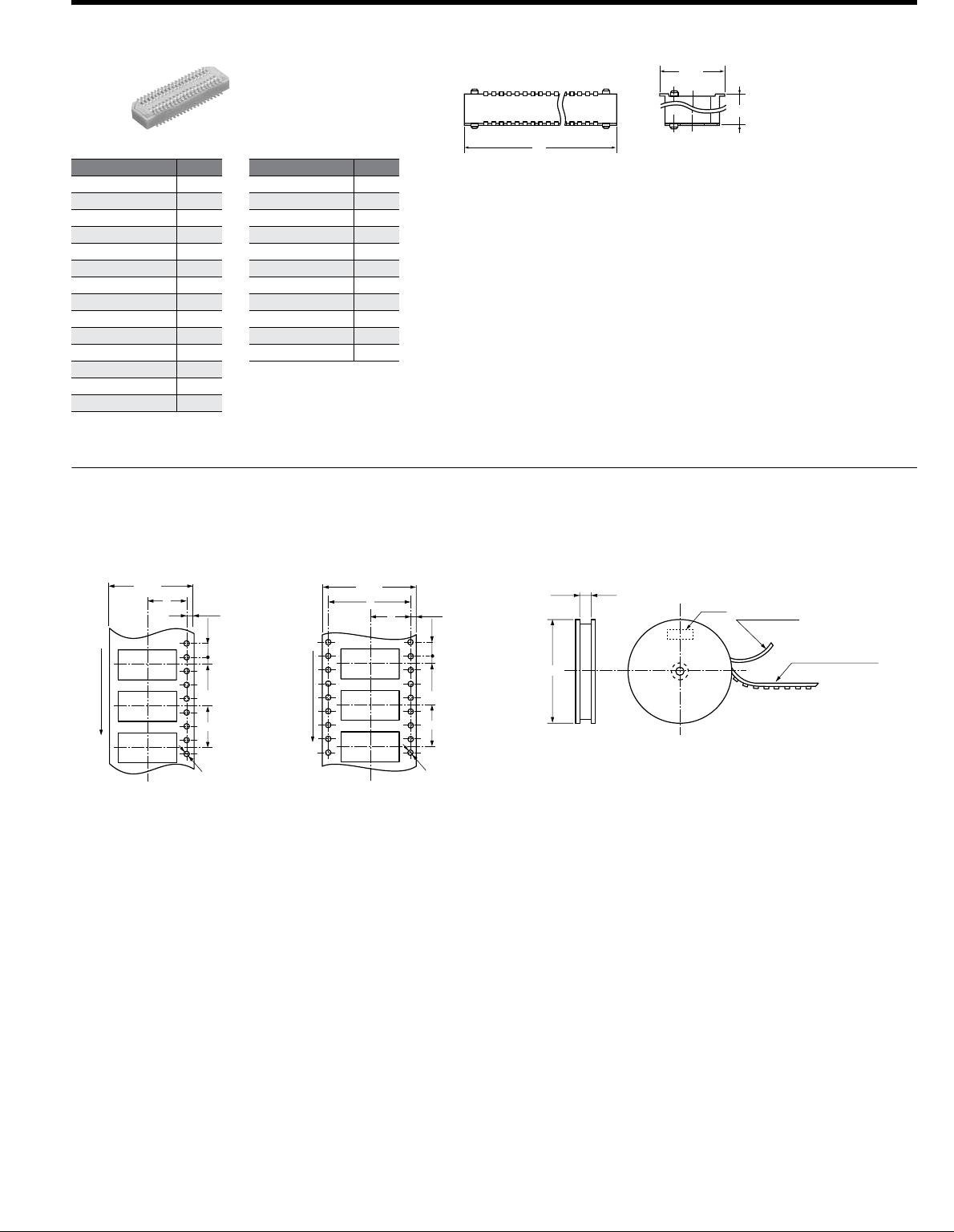

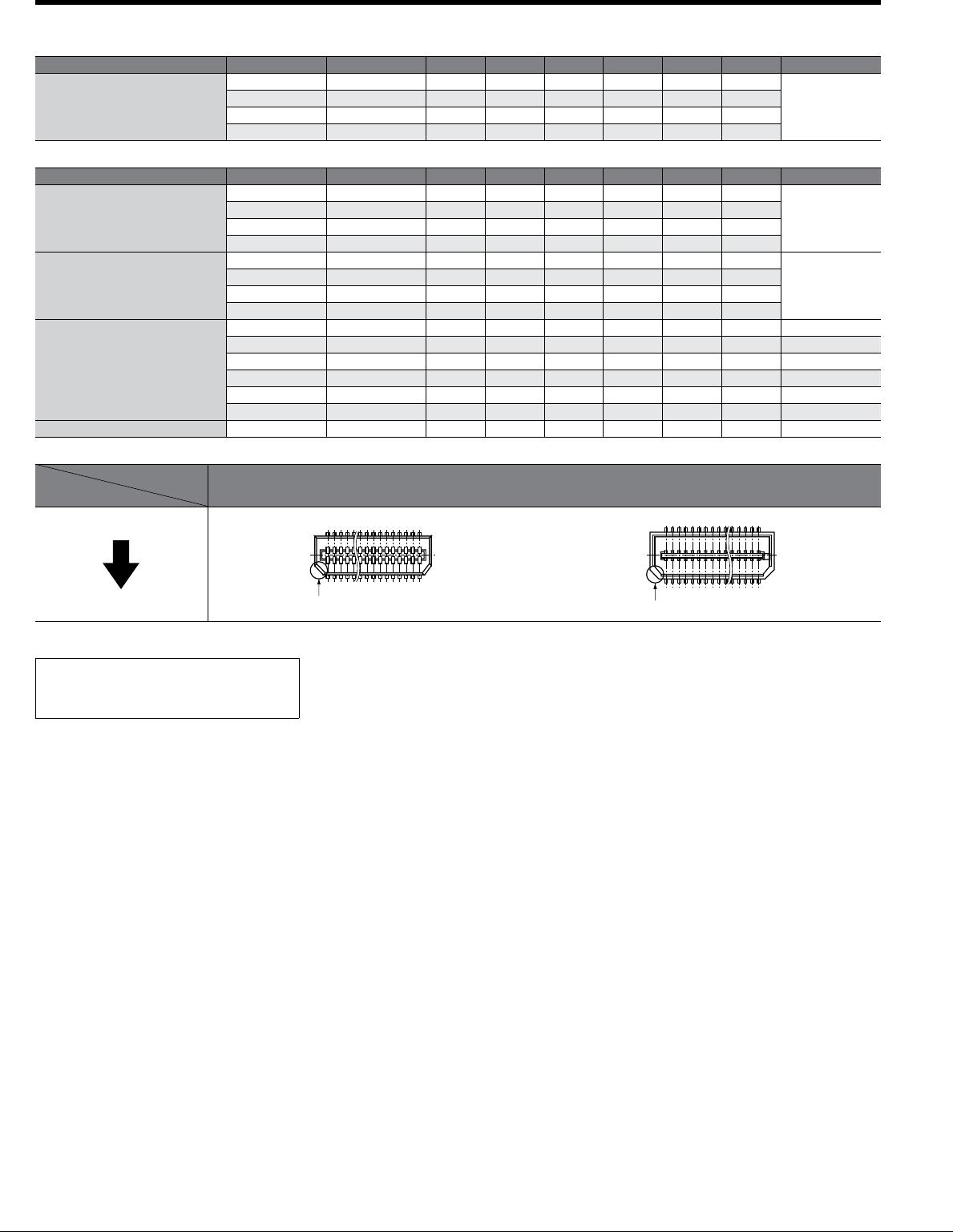

Regarding the design of devices and PC board patterns

Regarding the selection of the connector placement machine and the mounting

procedures

Notes on Using Narrow pitch Connectors

1) When connecting several connectors

together by stacking, make sure to

maintain proper accuracy in the design of

structure and mounting equipment so

that the connectors are not subjected to

twisting and torsional forces.

2) With mounting equipment, there may

be up to a ±0.2 to 0.3-mm error in

positioning. Be sure to design PC boards

and patterns while taking into

consideration the performance and

abilities of the required equipment.

3) Some connectors have tabs embossed

on the body to aid in positioning. When

using these connectors, make sure that

the PC board is designed with positioning

holes to match these tabs.

4) To ensure the required mechanical

strength when soldering the connector

terminals, make sure the PC board

meets recommended PC board pattern

design dimensions given.

5) For all connectors of the narrow pitch

series, to prevent the PC board from

coming off during vibrations or impacts,

and to prevent loads from falling directly

on the soldered portions, be sure to

design some means to fix the PC board

in place.

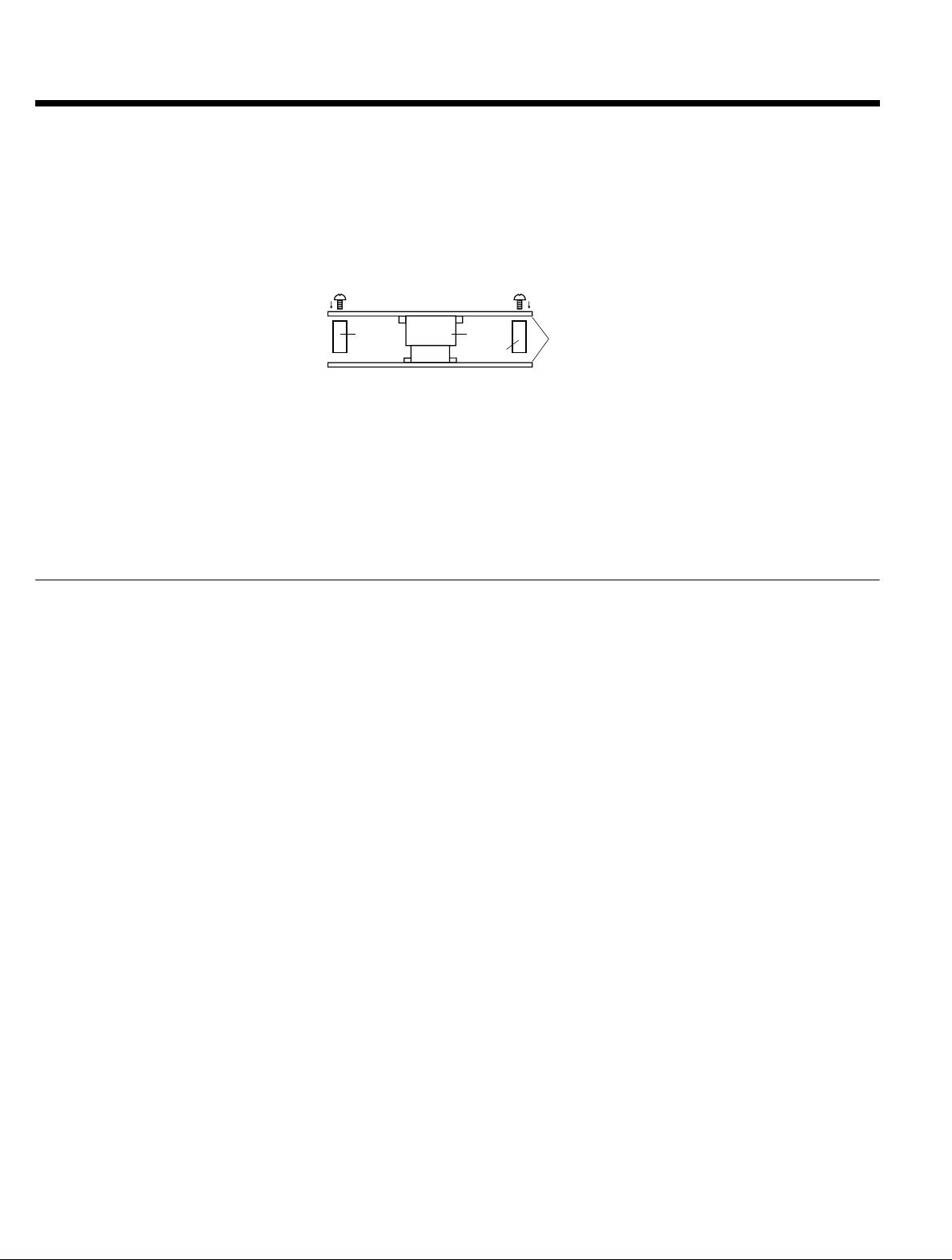

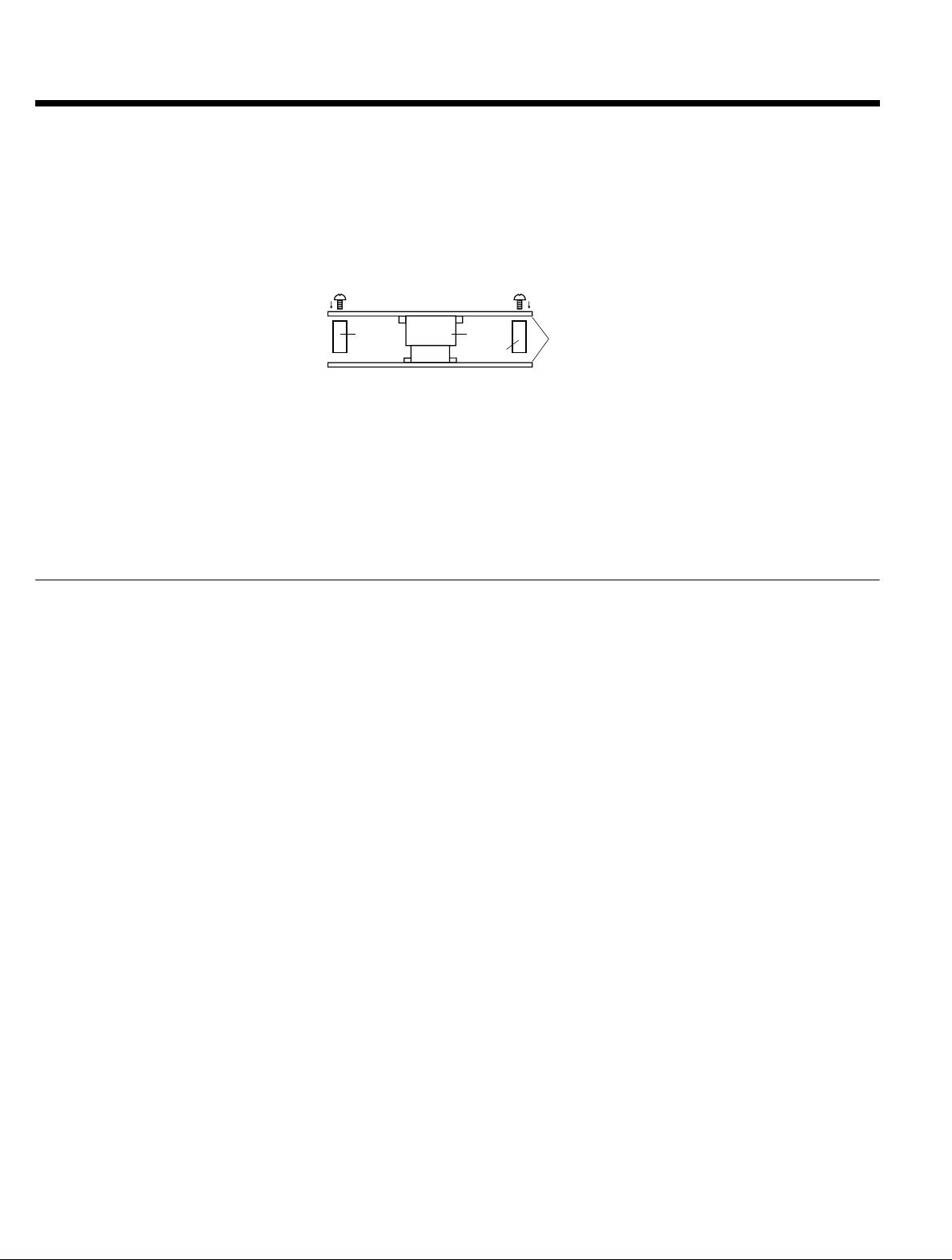

Example) Secure in place with screws

When connecting PC boards, take

appropriate measures to prevent the

connector from coming off.

6) Notes when using a FPC.

(1) When the connector is soldered to an

FPC board, during its insertion and

removal procedures, forces may be

applied to the terminals and cause the

soldering to come off. It is recommended

to use a reinforcement board on the

backside of the FPC board to which the

connector is being connected. Please

make the reinforcement board

dimensions bigger than the outer limits of

the recommended PC board pattern

(should be approximately 1 mm greater

than the outer limit).

Material should be glass epoxy or

polyimide, and the thickness should be

between 0.2 and 0.3 mm.

(2) Collisions, impacts, or turning of FPC

boards, may apply forces on the

connector and cause it to come loose.

Therefore, make to design retaining

plates or screws that will fix the connector

in place.

7) The narrow pitch connector series is

designed to be compact and thin.

Although ease of handling has been

taken into account, take care when

mating the connectors, as displacement

or angled mating could damage or

deform the connector.

Connector

Spacer

Spacer

PC board

Screw

1) Select the placement machine taking

into consideration the connector height,

required positioning accuracy, and

packaging conditions.

2) Be aware that if the catching force of

the placement machine is too great, it

may deform the shape of the connector

body or connector terminals.

3) Be aware that during mounting,

external forces may be applied to the

connector contact surfaces and terminals

and cause deformations.

4) Depending on the size of the

connector being used, self alignment

may not be possible. In such cases, be

sure to carefully position the terminal with

the PC board pattern.

5) The positioning bosses give an

approximate alignment for positioning on

the PC board. For accurate positioning of

the connector when mounting it to the PC

board, we recommend using an

automatic positioning machine.

6) Excessive mounter chucking force may

deform the molded or metal part of the

connector. Consult us in advance if

chucking is to be applied.