Technical Note

6/8

BD63843EFV, BD63847EFV

www.rohm.com

2012.02 - Rev.

© 2012 ROHM Co., Ltd. All rights reserved.

●Usage Notes

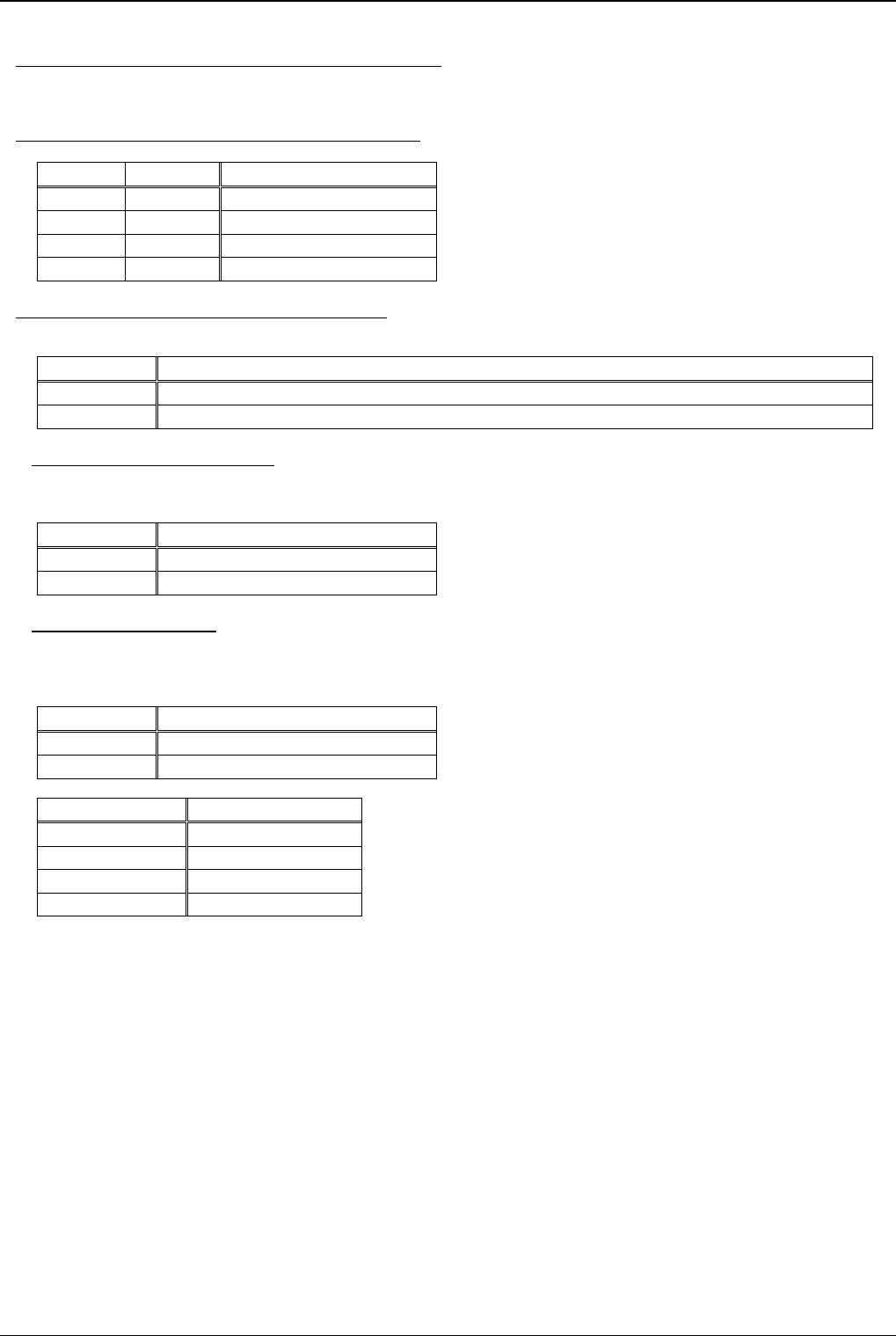

(1) Absolute maximum ratings

An excess in the absolute maximum ratings, such as supply voltage, temperature range of operating conditions, etc., can

break down the devices, thus making impossible to identify breaking mode, such as a short circuit or an open circuit. If

any over rated values will expect to exceed the absolute maximum ratings, consider adding circuit protection devices,

such as fuses.

(2) Connecting the power supply connector backward

Connecting of the power supply in reverse polarity can damage IC. Take precautions when connecting the power supply

lines. An external direction diode can be added.

(3) Power supply Lines

As return of current regenerated by back EMF of FET output happens, take steps such as putting capacitor between

power supply and GND as an electric pathway for the regenerated current. Be sure that there is no problem with each

property such as emptied capacity at lower temperature regarding electrolytic capacitor to decide capacity value. If the

connected power supply does not have sufficient current absorption capacity, regenerative current will cause the voltage

on the power supply line to rise, which combined with the product and its peripheral circuitry may exceed the absolute

maximum ratings. It is recommended to implement a physical safety measure such as the insertion of a voltage clamp

diode between the power supply and GND pins.

(4) GND Potential

The potential of GND pin must be minimum potential in all operating conditions.

(5) Metal on the backside (Define the side where product markings are printed as front)

The metal on the backside is shorted with the backside of IC chip therefore it should be connected to GND. Be aware that

there is a possibility of malfunction or destruction if it is shorted with any potential other than GND.

(6) Thermal design

Use a thermal design that allows for a sufficient margin in light of the power dissipation (Pd) in actual operating conditions.

This IC exposes the metal on the backside of package. Note that this part is assumed to use after providing heat

dissipation treatment to improve heat dissipation efficiency. Try to occupy as wide as possible with heat dissipation

pattern not only on the board surface but also the backside.

(7) Inter-pin shorts and mounting errors

When attaching to a printed circuit board, pay close attention to the direction of the IC and displacement. Improper

attachment may lead to destruction of the IC. There is also possibility of destruction from short circuits which can be

caused by foreign matter entering between outputs or an output and the power supply or GND.

(8) Operation in a strong electric field

Use caution when using the IC in the presence of a strong electromagnetic field as doing so may cause the IC to

malfunction.

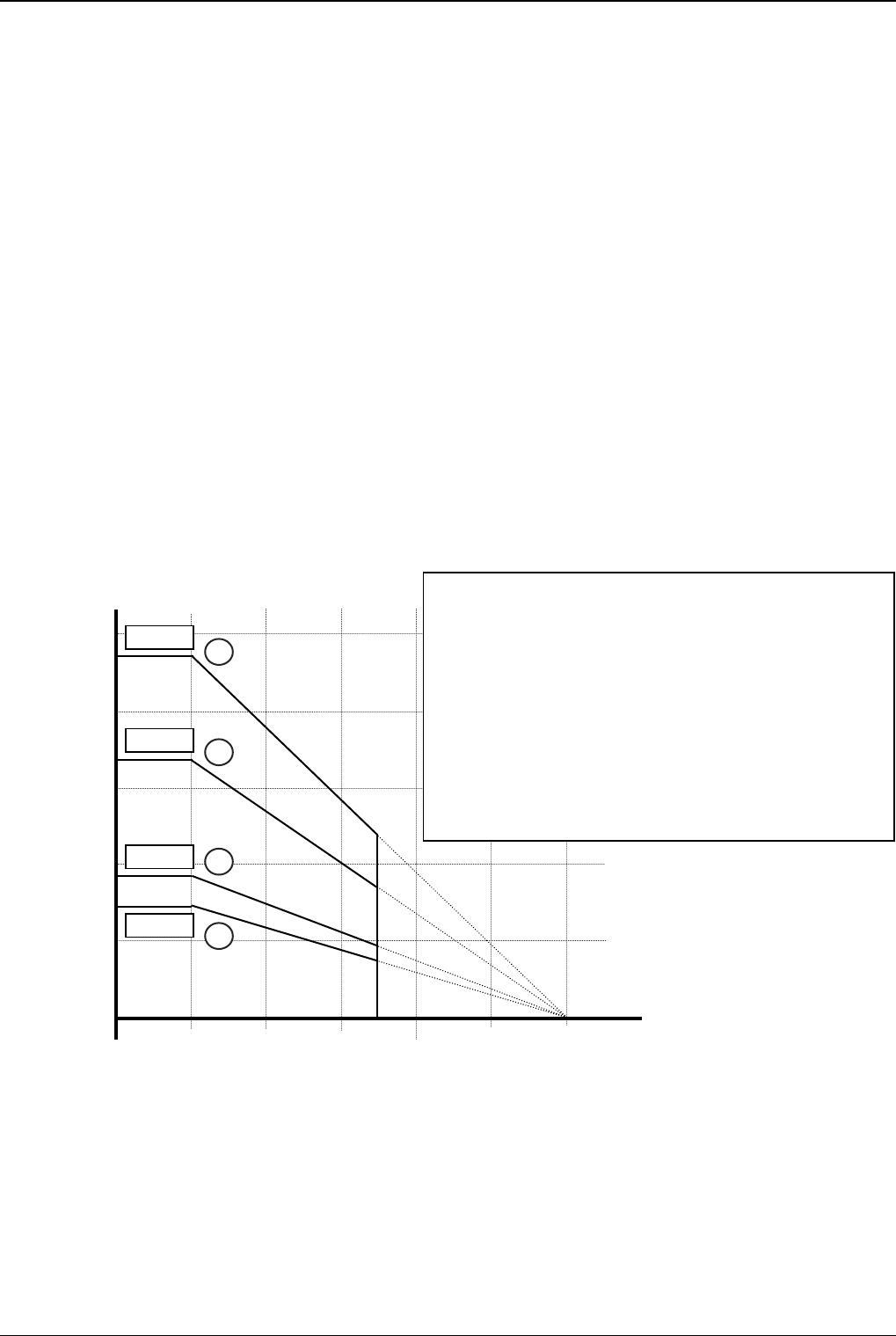

(9) ASO

When using the IC, set the output transistor so that it does not exceed absolute maximum ratings or ASO.

(10) Thermal shutdown circuit

The IC has a built-in thermal shutdown circuit (TSD circuit). If the chip temperature becomes Tjmax=150°C, and higher,

coil output to the motor will be open. The TSD circuit is designed only to shut the IC off to prevent runaway thermal

operation. It is not designed to protect or indemnify peripheral equipment. Do not use the TSD function to protect

peripheral equipment.

TSD on temperature [°C] (Typ.) Hysteresis temperature [°C] (Typ.)

175 25

(11) Inspection of the application board

During inspection of the application board, if a capacitor is connected to a pin with low impedance there is a possibility

that it could cause stress to the IC, therefore an electrical discharge should be performed after each process. Also, as a

measure again electrostatic discharge, it should be earthed during the assembly process and special care should be

taken during transport or storage. Furthermore, when connecting to the jig during the inspection process, the power

supply should first be turned off and then removed before the inspection.