Freescale reserves the right to change the detail specifications as may be required to permit

improvements in the design of its products.

Freescale Semiconductor Document Number: MPXC2011DT1

Data Sheet: Technical Data Rev. 11, 09/2015

© 2010, 2012, 2014, 2015 Freescale Semiconductor, Inc. All rights reserved.

MPXC2011DT1, 0 to 10 kPa,

Differential, Compensated Pressure

Sensor

Freescale Semiconductor has developed a high volume, miniature pressure

sensor package which is ideal as a sub-module component or a disposable unit.

The unique concept of the Chip Pak allows great flexibility in system design while

providing an economic solution for the designer. This new chip carrier package

uses Freescale Semiconductor's unique sensor die with its piezoresistive

technology, along with the added feature of on-chip, thin-film temperature

compensation and calibration.

Features

• Integrated temperature compensation and calibration

• Ratiometric to supply voltage

• Polysulfone case material (ISO 10993)

• Provided in easy-to-use tape and reel

Typical applications

• Respiratory diagnostics

• Air movement control

• Controllers

• Pressure switching

NOTE

The die and wire bonds are exposed on the front side of the chip

pak (pressure is applied to the backside of the device). Front

side die and wire protection must be provided in the customer's

housing. Use caution when handling the devices during all

processes.

Ordering Information

Device Name Shipping Package

Pressure Type

Device Marking

Gauge Differential Absolute

MPXC2011DTI

Tape and Reel 98ASB13355C •

XXXX = Device code

XXX = Trace code

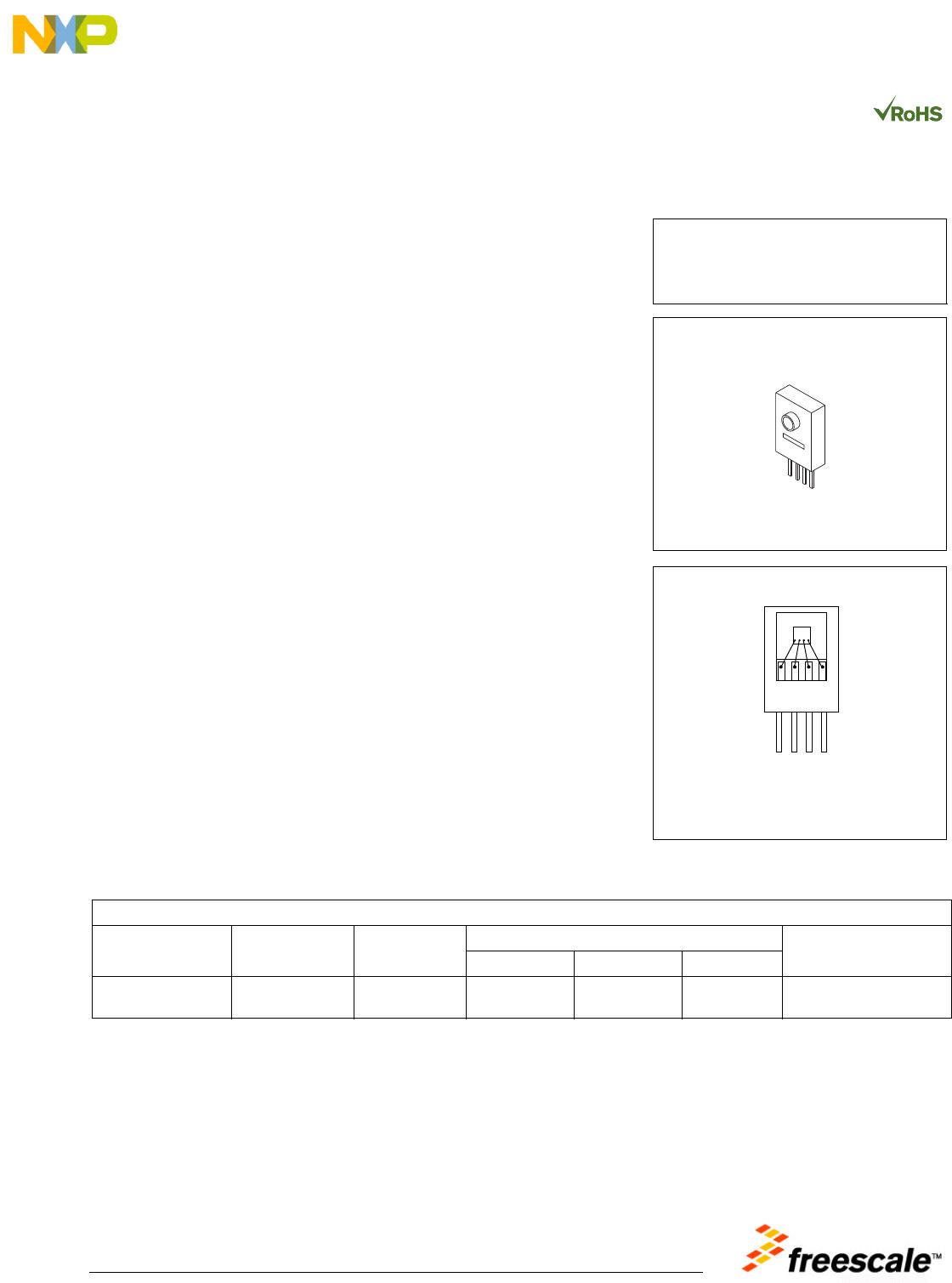

1234

GND

+V

OUT

+V

S

–V

OUT

MPXC2011DT1

Chip Pak package

Back view

MPXC2011DT1

Case 98ASB13355C

Front view

Pinout