12

Testing Digital Fiber Optic Links

The overall performance of a complete digital fiber optic

link can be determined by stimulating the transmitter

with a pseudo random bit sequence (PRBS) data source

while observing the response at the receiver’s output. A

PRBS data source is a shift register where data bits from

two or more shift register stages are combined using an

exclusive-or gate. When a clock signal is applied to the CLK

input of the shift register, and the output of the exclusive

OR gate is applied to the D

S

input of the shift register, the

PRBS generator produces a serial bit stream which appears

to be random, but is actually periodic and reproducible. If

the PRBS generator is constructed using a 23 bit long shift

register, the exclusive OR feedback can be configured so

that the shift register will be in one of 2

23

-1 possible states

at any given clock time. The 2

23

-1 PRBS data generator

appears to be a source of random serial data, but it is

actually the output of a shift register which is in one of

8,388,610 precisely repeatable states. PRBS generators

send an exactly repeating serial data pattern that can be

checked bit-by-bit to determine if the fiber optic link made

errors while transporting the data. A bit-error-ratio test set

is an instrument which contains a PRBS generator, a bit-by-

bit error detector, and an error counter. Bit-error-ratio test

sets measure the probability that the fiber optic link will

make an error. Probability of error is commonly expressed

as a bit-error-ratio or BER. The BER is simply the number of

errors which occurred divided by the number of bits trans-

mitted through the fiber optic link in some arbitrary time

interval.

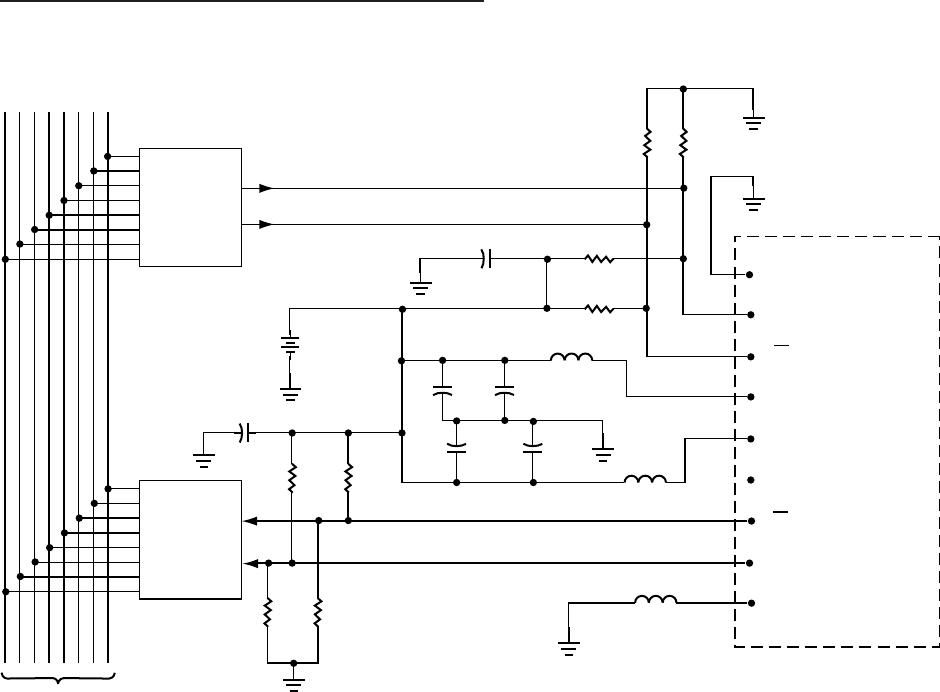

The +5 V ECL interface of the transceiver shown in Figure

8 is convenient for use with off-the-shelf VLSI chips like the

TAXIchip, but it is not compatible with the majority of the

test equipment used to measure the performance of fiber

optic links. Most bit error rate (BER) test sets have conven-

tional -5 V ECL inputs and outputs. The test fixture shown in

Figure 12 provides a convenient way to convert +5 V ECL to

-5 V ECL. This test fixture allows the transceiver in Figure 8

to be used with any BER test set (BER machine) with a con-

ventional -5V ECL interface. The test fixture in Figure 12

was used to collect the performance data shown in this

application note.

The waveforms shown in Figures 13 and 14 are known as

eye diagrams. These eye diagrams were measured by con-

necting a digitizing oscilloscope, with a 1 GHz bandwidth,

to the receiver’s +5 V ECL output. The Agilent 54100A

oscilloscope used for these measurements was triggered

from the PRBS generator’s clock. The lack of correla-

tion between the oscilloscope’s time base, and the PRBS

generator’s clock, assures that the oscilloscope will ran-

domly sample the PRBS data. The infinite persistence mode

of the Agilent 54100A Digitizing Oscilloscope was used,

and the electrical output of the receiver was measured

for roughly 1 hour, to determine the eye opening. As eye

opening, or eye width, increases, the probability that the

fiber optic link will make an error decreases. A wide eye

opening makes it easier to extract the clock signal which is

normally encoded with the data passing through the serial

communication channel. Fiber optic links are less likely to

make errors when the eye is wide open, because there is

more time for the clock to synchronously detect the data

while it is stable and unchanging.

The results shown in Figure 13 were obtained at room

temperature when 125 MBd PRBS data was transmitted

through a plastic fiber optic link. Figure 13 shows that the

eye opening is typically 5.52 ns when the recommended

transceiver in Figure 8 is used with 20 m of 1 mm plastic

fiber. Excellent performance can also be achieved by using

the transceiver in Figure 8 with Avago’s 200 µm HCS

TM

fiber.

Figure 14 indicates that the eye opening is typically 5.56 ns

wide when 125 MBd data is transmitted through 100 m of

200 µm HCS

TM

fiber.

A better method for measuring the performance of a

complete optical data link is to use a computer controlled

delay line and a BER test set. This technique uses a com-

puter to adjust the delay of the BER test set’s clock relative

to the PRBS data. At a data rate of 125 MBd the clock delay

was changed in 100 ps increments. The test system then

measures and stores the probability of error at each 100

ps delay step until the clock has been swept through the

entire 8.0 ns period of every 125 MBd symbol transmitted

through the fiber optic link. The results in Figure 15 were

obtained when the BER test set applied 2

23

-1 PRBS data

to the transmitter portion of the transceiver under evalu-

ation. Figure 15 shows that when using the transceiver

recommended in Figure 8 BER is typically ≤ 1 x 10

-10

for 5.8

ns of each pseudo random symbol transmitted through

a 20 m length of 1 mm plastic fiber. The optical power

applied to the receiver was Pr = -16.4 dBm average for the

measured results shown in Figure 15. Figure 16 shows the

performance that can be achieved at 125 MBd with 200

µm HCS

TM

fiber. Figure 16 shows that when using the trans-

ceiver recommended in Figure 8, BER will be typically ≤ 1 x

10

-10

for 5.3 ns of each pseudo random symbol transmitted

through a 100 m length of 200 µm HCS

TM

fiber. The optical

power applied to the receiver was Pr = -18.0 dBm average

for the measured results shown in Figure 16.