Design and specifications are each subject to change without notice. Ask factory for the current technical specifications before purchase and/or use.

Should a safety concern arise regarding this product, please be sure to contact us immediately.

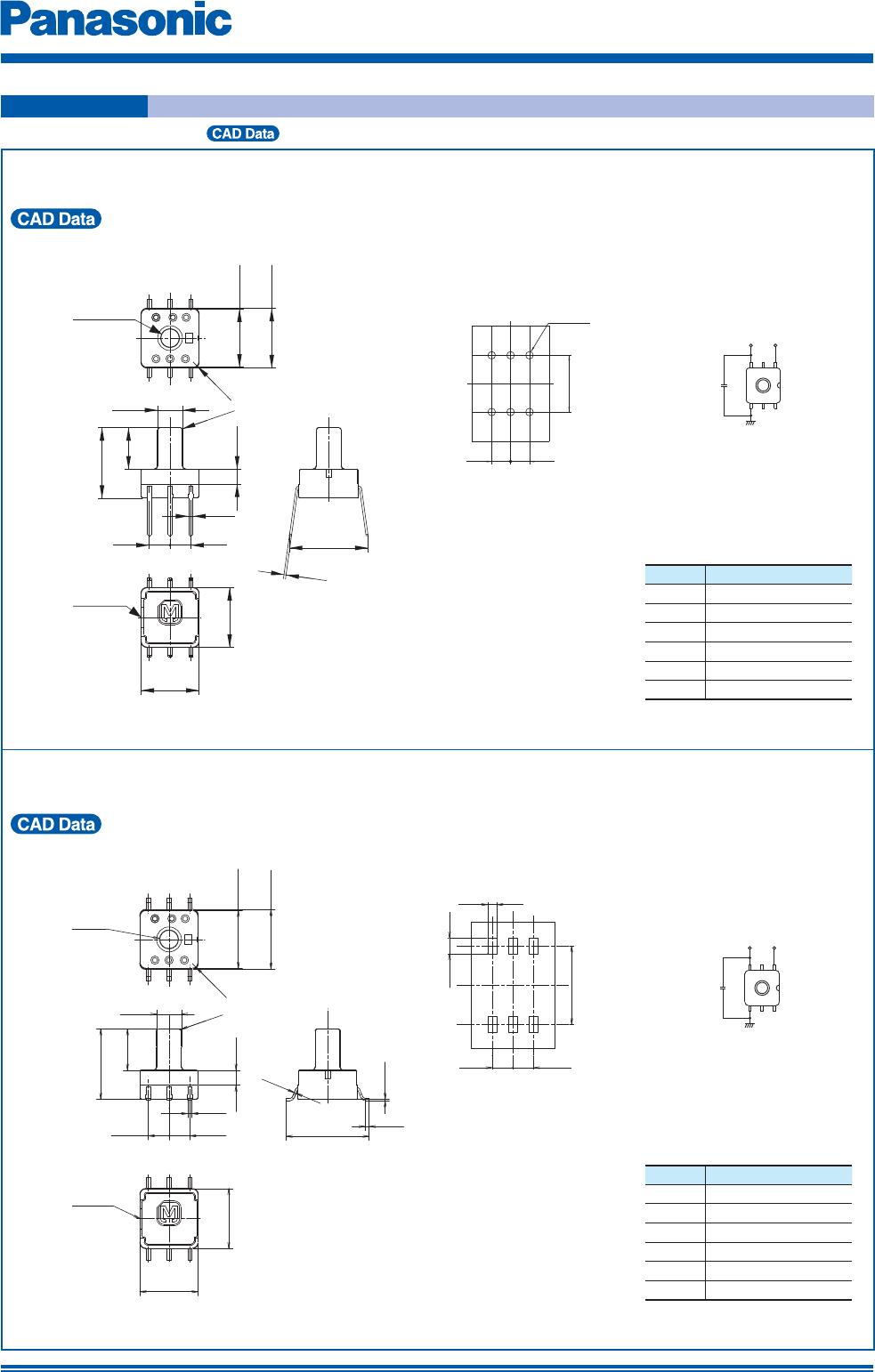

Pressure Sensor/PS-A (ADP5)

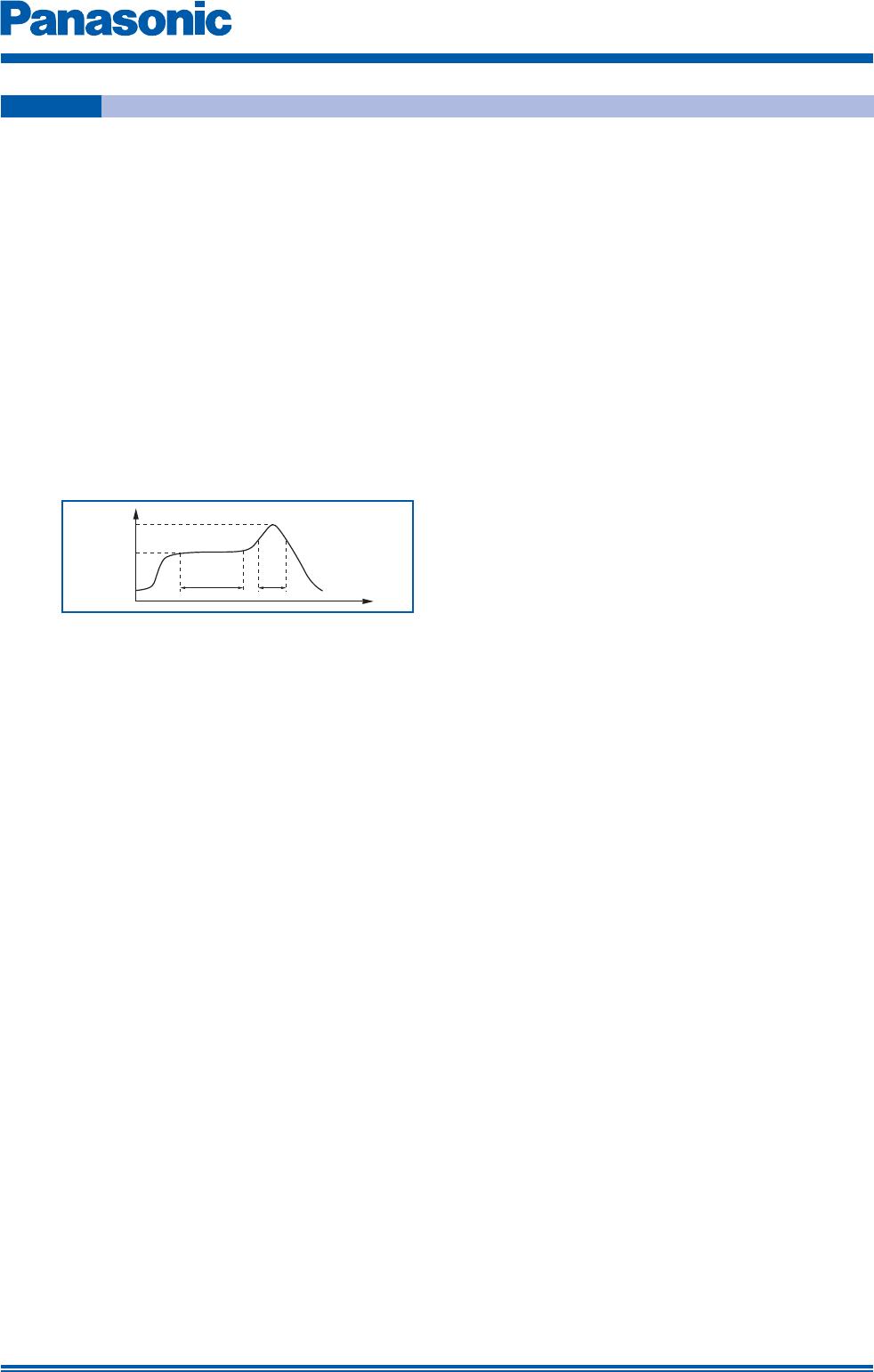

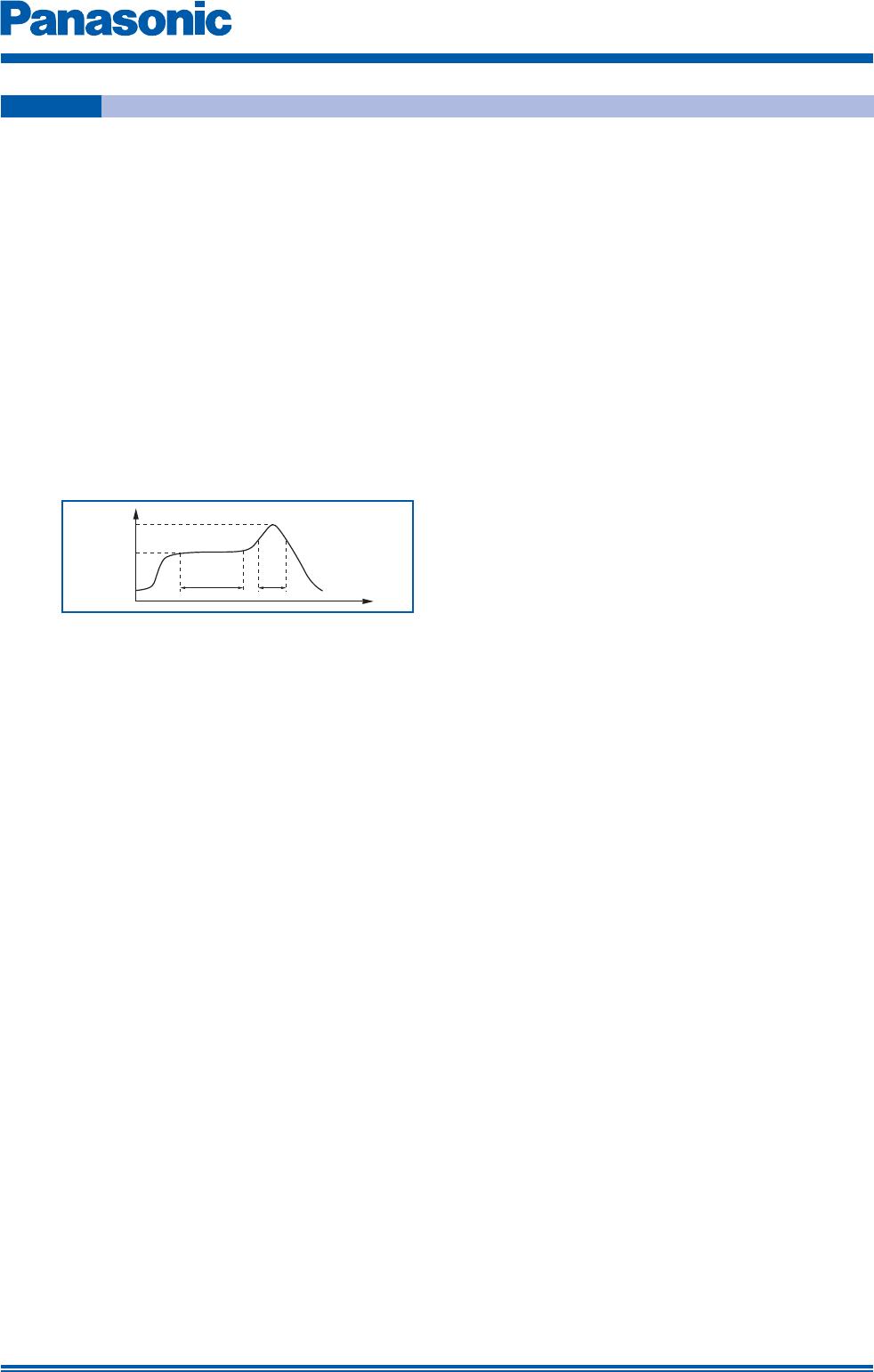

Preheating

With in 60 sec.

With in

10 sec.

230 °C

150 °C

446 °F

302 °F

Main heating

Temperature

Time

NOTES

■ Mounting

Use the land of the printed-circuit board on which the sensor is

securely fixed.

■ Soldering

Avoid the external thermal influence as the product has a limited

thermal capacity due to its compact structure. Heat deformation

may damage the sensor or deteriorate its performance. Use the

non-corrosive rosin flux. Prevent the flux from entering into the

inside of the product as the sensor is exposed to the atmosphere.

1) Manual soldering

• Raise the temperature of the soldering tip between 260 and

300 °C

500 and 572 °F (30 W) and solder within 5 seconds.

• The sensor output may vary if the load is applied on the

terminal during soldering.

• Keep the soldering tip clean.

2) DIP soldering (DIP Terminal)

• Keep the temperature of the DIP solder tank below 260 °C

572 °F and solder within 5 seconds.

• To avoid heat deformation, do not perform DIP soldering

when mounting on the circuit board which has a small

thermal capacity.

3) Reflow soldering (SMD Terminal)

• The recommended reflow temperature profile conditions are

given below.

• We recommend the screen solder printing method as the

method of cream.

• Please refer to the recommended PC board specification

diagram for the PC board foot pattern.

• Self alignment may not always work as expected, therefore,

please carefully the position of the terminals and pattern.

• The temperature of the profile is assumed to be a value

measured with the printed wiring board of the terminal

neighborhood.

• Please evaluate solderbility under the actual mounting

conditions since welding and deformation of the pressure

inlet port may occur due to heat stress depending on

equipments or conditions.

4) Rework soldering

• Complete rework at a time.

• Use a flattened soldering tip when performing rework on the

solder bridge. Do not add the flux.

• Keep the soldering tip below the temperature described in

the specifications.

5) Avoid drop and rough handling as excessive force may deform

the terminal and damage soldering characteristics.

6) Keep the circuit board warpage within 0.05 mm of the full width

of the sensor.

7) After soldering, do not apply stress on the soldered part when

cutting or bending the circuit board.

8) Prevent human hands or metal pieces from contacting with the

sensor terminal. Such contact may cause anomalous outlets as

the terminal is exposed to the atmosphere.

9) After soldering, prevent chemical agents from adhering to the

sensor when applying coating to avoid insulation deterioration of

the circuit board.

10

) Please consult us concerning leadfree soldering.

■ Wire connection

1) Correctly wire as in the connection diagram. Reverse connection

may damage the product and degrade the performance.

2) Do not use idle terminals to prevent damages to the sensor.

■ Cleaning

• Prevent cleaning liquid from entering the inside of the product

as the sensor is exposed to the atmosphere.

• Do not perform ultrasonic cleaning in order to prevent damages

to the product.

■ Environment

1) Avoid use and storage in the corrosive gas (organic solvent,

sulfurous acid and hydrogen sulfide gases) which negatively

affects the product.

2) Install the capacitor on the power supply terminal of the sensor

and stabilize supply voltage to maintain a superimposed noise

resistance. Recommended installation is to arrange 0.1 F and

1,000 pF in parallel. Before use, check the noise resistance and

select/add the optimal capacitor.

3) Use surge absorbers as applying the external surge voltage may

damage the internal circuit.

4) Malfunction may occur near electric noises from static electricity,

lightning, broadcast or amateur radio stations and mobile phones.

5) Avoid use in a place where these products come in contact with

water as the sensor does not have a splash-proof construction.

6) Avoid use in an environment where these products cause dew

condensation. When water attached to the sensor chip freezes,

the sensor output may be fluctuated or damaged.

7) Due to the structure of the pressure sensor chip, the output

varies under light. Do not expose the sensor chip to light when

applying a voltage by using a transparent tube.

8) Do not apply high-frequency oscillation, such as ultrasonic

waves, to the product.

■ Quality check under actual use conditions

These specifications are for individual components. Before use,

carefully check the performance and quality under actual use

conditions to enhance stability.

■ Other precautions

1) The wrong mounting method and the pressure range may invite

the risk of accidents.

2) Only applicable pressure medium is dry air. Avoid use in the

corrosive gas (organic solvent, sulfurous acid and hydrogen

sulfide gases) or other mediums containing moisture or foreign

substances. Such mediums may damage or break the product.

3) The pressure sensor chip is located inside the pressure

introduction port. Do not insert foreign substances, such as

wires, into the port as those substances may damage the chip

and close the port. Do not block the atmosphere introduction

port.

4) Use electric power within the rated power range. Use beyond

the range may damage the product.

5) Follow below instructions as static electricity may damage the

product:

(1) For Storage, short the circuit between terminals by using

conductive substances or wrap the whole chip with

aluminum foil. For storage and transportation, avoid plastic

containers which are easily electrified.

(2) Before use, connect electrified materials on desk and

operators to the ground in order to safely discharge static

electricity.

6) Carefully select and fix tubes, introduction pipes and products

based on the working voltage. Please contact us for any inquires.

7) After mounding the pressure sensor, prevent the potting agent

from entering the pressure and the atmosphere introduction ports

when coating the circuit board. Use the elastic resin as the heated

resin may expand, contract and apply pressure to the sensor. After

coating, carefully check if the sensor can be used.

Aug. 201500