LTC4079

17

4079f

For more information www.linear.com/LTC4079

Typical applicaTions

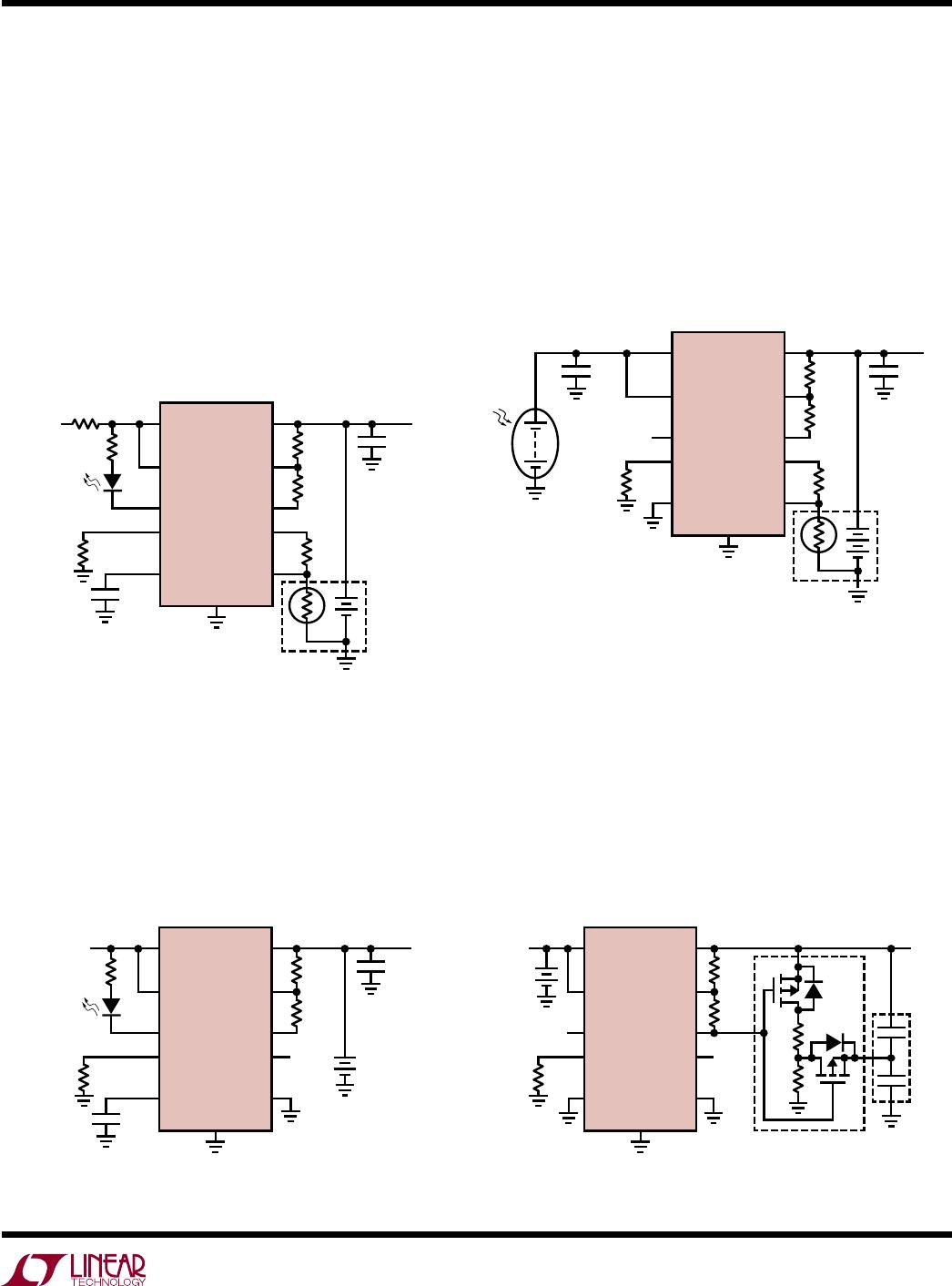

Li-Ion Charger with Timer Termination

In the Figure 8 configuration, the input source charges

the battery for 5½ hours and also supplies current to the

load. The maximum current provided by the charger (on

BAT pin) is limited to the charge current of 246mA set by

the 1.21k resistor on the PROG pin. A small resistor is

used in series with the input supply to reduce V

IN

-V

BAT

,

and thereby increase the available charge current during

thermal regulation. Once the battery is charged, it sup

-

plies power to the load until V

BAT

falls below the recharge

threshold, at which point a recharge cycle starts.

Figure 8. Li-Ion Charger with Timer Termination

BAT

FB

FBG

EN

NTCBIASPROG

NTC

GND

LTC4079

TIMER

1.54M

1.21k

25Ω, 2W

100nF

1µF

TO

LOAD

249k

10k

4079 F08

BATTERY

PACK

V

CHG

= 8.4V

I

CHG

= 246mA

CHRG

IN

24V

SUPPLY

+

T

10k

2-Cell NiMH Trickle Charger from Automotive Supply

with Timer Termination

Figure 9 shows a trickle charger for 2-cell, 2500mAh,

AA NiMH battery with timer termination after 31 hours.

Charge current drops when the battery voltage reaches

1.65V per cell.

Figure 9. NiMH Trickle Charger with Timer Termination

BAT

FB

FBG

EN

NTCBIASPROG

NTC

GND

LTC4079

TIMER

324k

3.01k

560nF

1µF

TO

LOAD

178k

4079 F09

2500mAh

2-CELL

NiMH

V

CHG

= 3.3V

I

CHG

= 99mA

CHRG

IN

12V

CAR BATTERY

+

Li-Ion Charging from a Solar Panel with Differential

Voltage Regulation, C/10 Termination

Figure 10 shows a simple charging solution from a solar

panel. Differential voltage regulation reduces charge current

to prevent the panel voltage from drooping below the

battery voltage when charging under low light conditions.

The LTC4079 does not require a Schottky diode in series

with the panel.

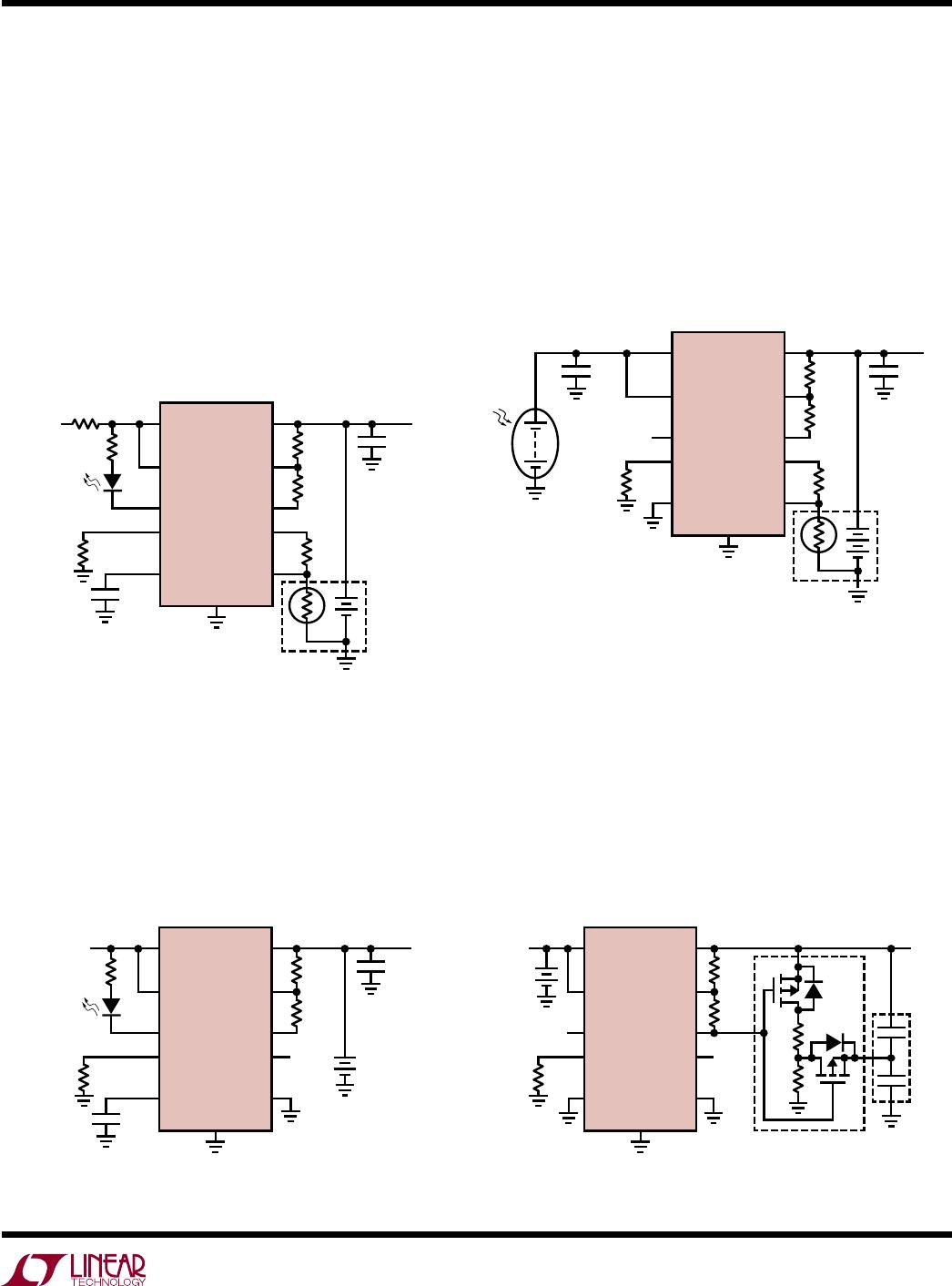

Supercapacitor Charger from 2-Cell Li-ion

Charging terminates when the stacked supercapacitor

voltage reaches the set charge voltage. A recharge cycle

begins automatically when the supercap voltage falls

below the recharge threshold. A resistor divider balancer

can optionally be switched in for balancing a stacked

supercapacitor during charging.

Figure 10. Li-Ion Charger with Differential Voltage Regulation

BAT

FB

FBG

EN

NTCBIASPROG

NTC

GND

LTC4079

TIMER

1.54M

1.21k

1µF1µF

TO

LOAD

249k

10k

4079 F10

BATTERY

PACK

V

CHG

= 8.4V

I

CHG

= 246mA

CHRG

IN

+

SOLAR

PANEL

+

–

T

10k

Figure 11. Supercap Charger with C/10 Termination

BAT

2-CELL

Li-Ion

FB

FBG

EN

NTCBIASPROG

NTC

GND

LTC4079

TIMER

1.02M

30.1k

C

SC

0.6F

HS206

TO

LOAD

309k

1k

1k

SUPERCAP BALANCER (OPTIONAL)

FDG6308P

4079 F11

V

CHG

= 5.0V

I

CHG

= 10mA

CHRG

IN

+