8

Such a circuit oers several advantages. First the voltage

outputs of two diodes are added in series, increasing the

overall value of voltage sensitivity for the network (com-

pared to a single diode detector). Second, the RF imped-

ances of the two diodes are added in parallel, making

the job of reactive matching a bit easier. Such a circuit

can easily be realized using the two series diodes in the

HSMS-285C.

Flicker Noise

Reference to Figure 5 will show that there is a junc-

tion of metal, silicon, and passivation around the rim

of the Schottky contact. It is in this three-way junction

that icker noise

[5]

is generated. This noise can severely

reduce the sensitivity of a crystal video receiver utiliz-

ing a Schottky detector circuit if the video frequency is

below the noise corner. Flicker noise can be substantially

reduced by the elimination of passivation, but such

diodes cannot be mounted in non-hermetic packages.

p-type silicon Schottky diodes have the least icker noise

at a given value of external bias (compared to n-type

silicon or GaAs). At zero bias, such diodes can have

extremely low values of icker noise. For the HSMS-285x

series, the noise temperature ratio is given in Figure 14.

Any Schottky junction, be it an RF diode or the gate of

a MESFET, is relatively delicate and can be burned out

with excessive RF power. Many crystal video receivers

used in RFID (tag) applications nd themselves in poorly

controlled environments where high power sources may

be present. Examples are the areas around airport and

FAA radars, nearby ham radio operators, the vicinity of

a broadcast band transmitter, etc. In such environments,

the Schottky diodes of the receiver can be protected

by a device known as a limiter diode.

[6]

Formerly avail-

able only in radar warning receivers and other high cost

electronic warfare applications, these diodes have been

adapted to commercial and consumer circuits.

Avago oers a complete line of surface mountable

PIN limiter diodes. Most notably, our HSMP-4820 (SOT-

23) can act as a very fast (nanosecond) power-sensi-

tive switch when placed between the antenna and the

Schottky diode, shorting out the RF circuit temporar-

ily and reecting the excessive RF energy back out the

antenna.

Assembly Instructions

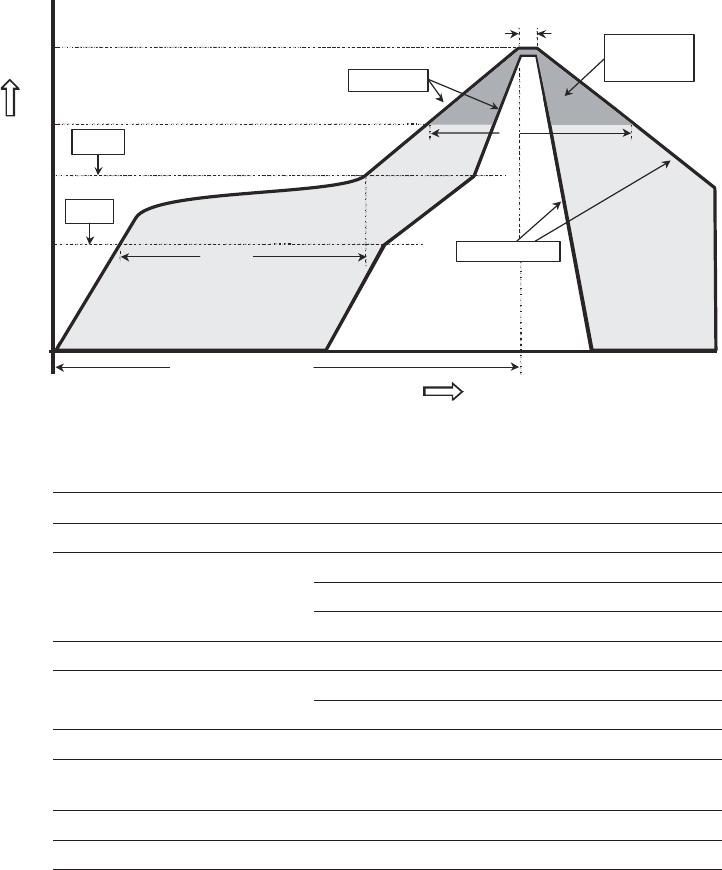

SOT-323 PCB Footprint

A recommended PCB pad layout for the miniature SOT-

323 (SC-70) package is shown in Figure 15 (dimensions

are in inches). This layout provides ample allowance for

package placement by automated assembly equipment

without adding parasitics that could impair the perfor-

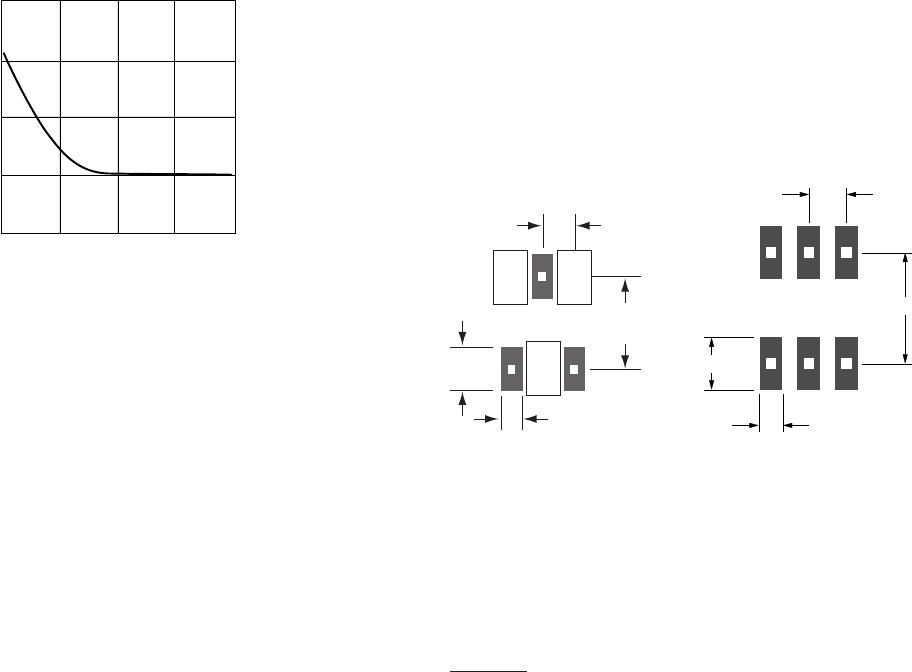

mance. Figure 16 shows the pad layout for the six-lead

SOT-363.

[4]

Avago Application Note 956-4, Schottky Diode Voltage Doubler.

[5]

Avago Application Note 965-3, Flicker Noise in Schottky Diodes.

[6]

Avago Application Note 1050, Low Cost, Surface Mount Power Limiters.

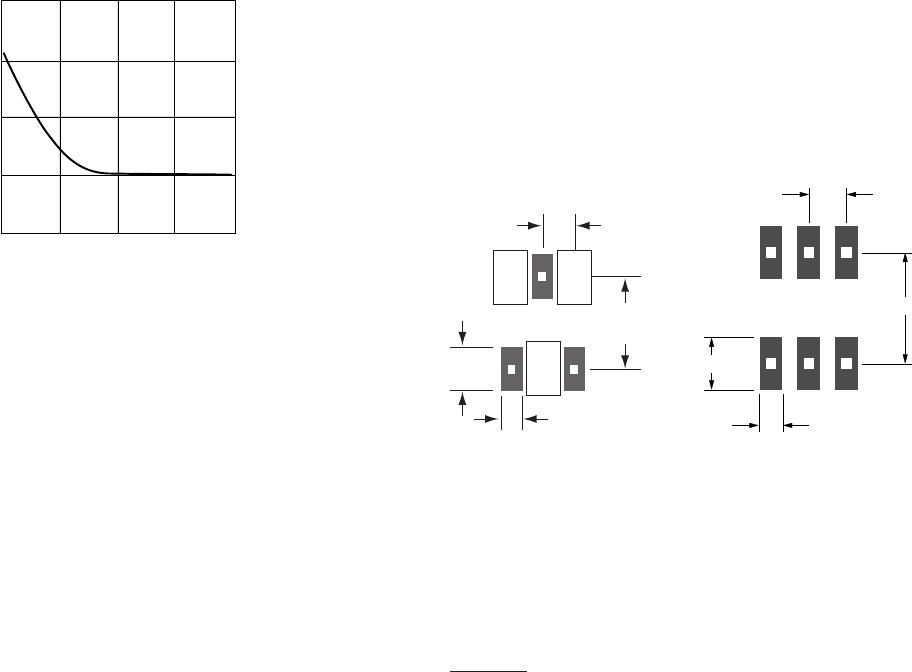

NOISE TEMPERATURE RATIO (dB)

FREQUENCY (Hz)

15

10

5

0

-5

10 100 1000 10000 100000

Diode Burnout

Figure 14. Typical Noise Temperature Ratio.

Noise temperature ratio is the quotient of the diode’s

noise power (expressed in dBV/Hz) divided by the noise

power of an ideal resistor of resistance R = R

V

.

For an ideal resistor R, at 300°K, the noise voltage can be

computed from

v = 1.287 X 10

-10

√R volts/Hz

which can be expressed as

20 log

10

v dBV/Hz

Thus, for a diode with R

V

= 9 KΩ, the noise voltage is

12.2 nV/Hz or -158 dBV/Hz. On the graph of Figure 14, -

158 dBV/Hz would replace the zero on the vertical scale

to convert the chart to one of absolute noise voltage vs.

frequency.

0.026

0.039

0.079

0.022

Dimensions in inches

Figure 15. Recommended PCB

Pad Layout for Avago’s SC70

3L/SOT-323 Products.

Figure 16. Recommended PCB Pad

Layout for Avago's SC70 6L/SOT-363

Products.