LT3080

10

3080fc

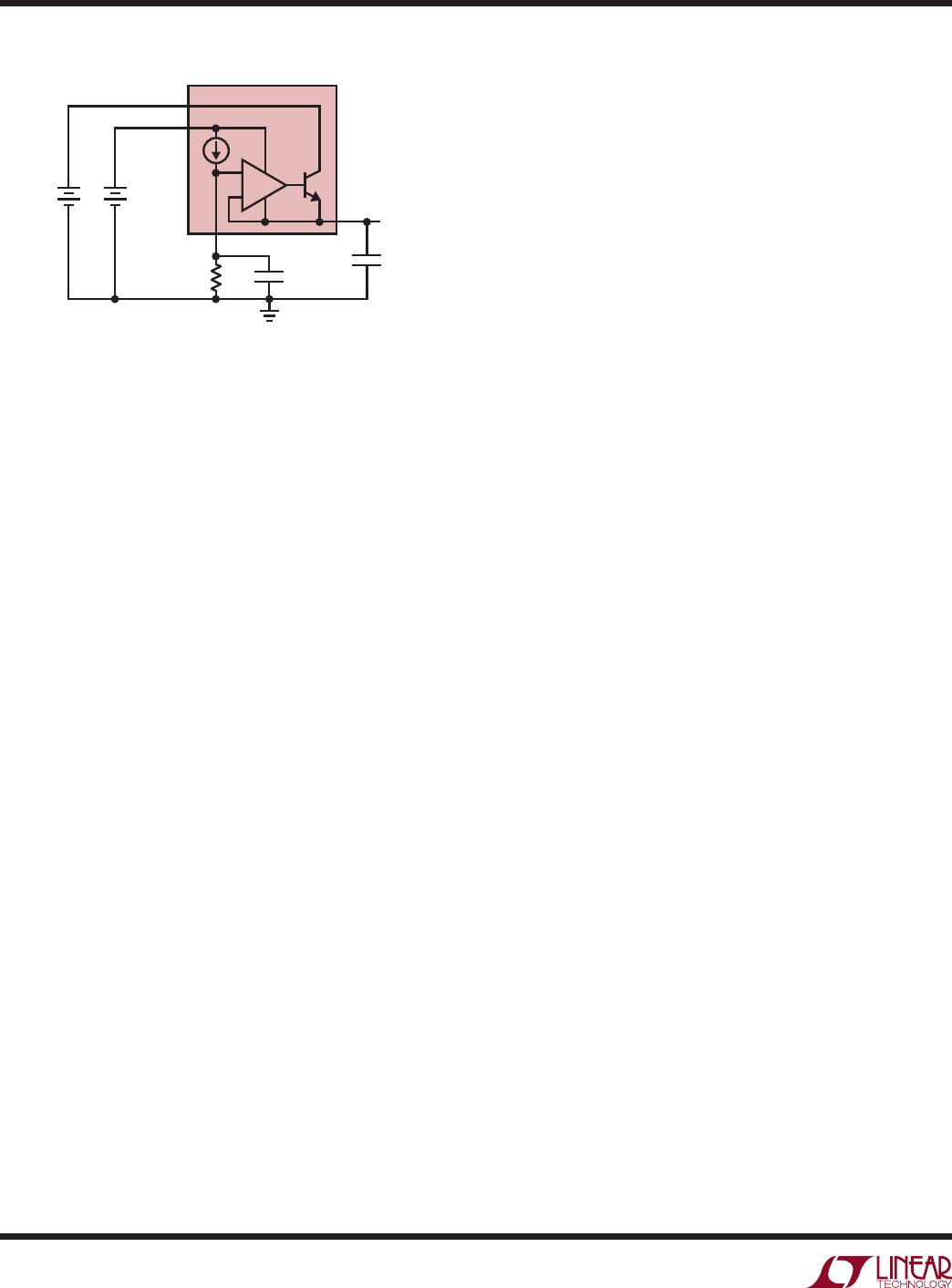

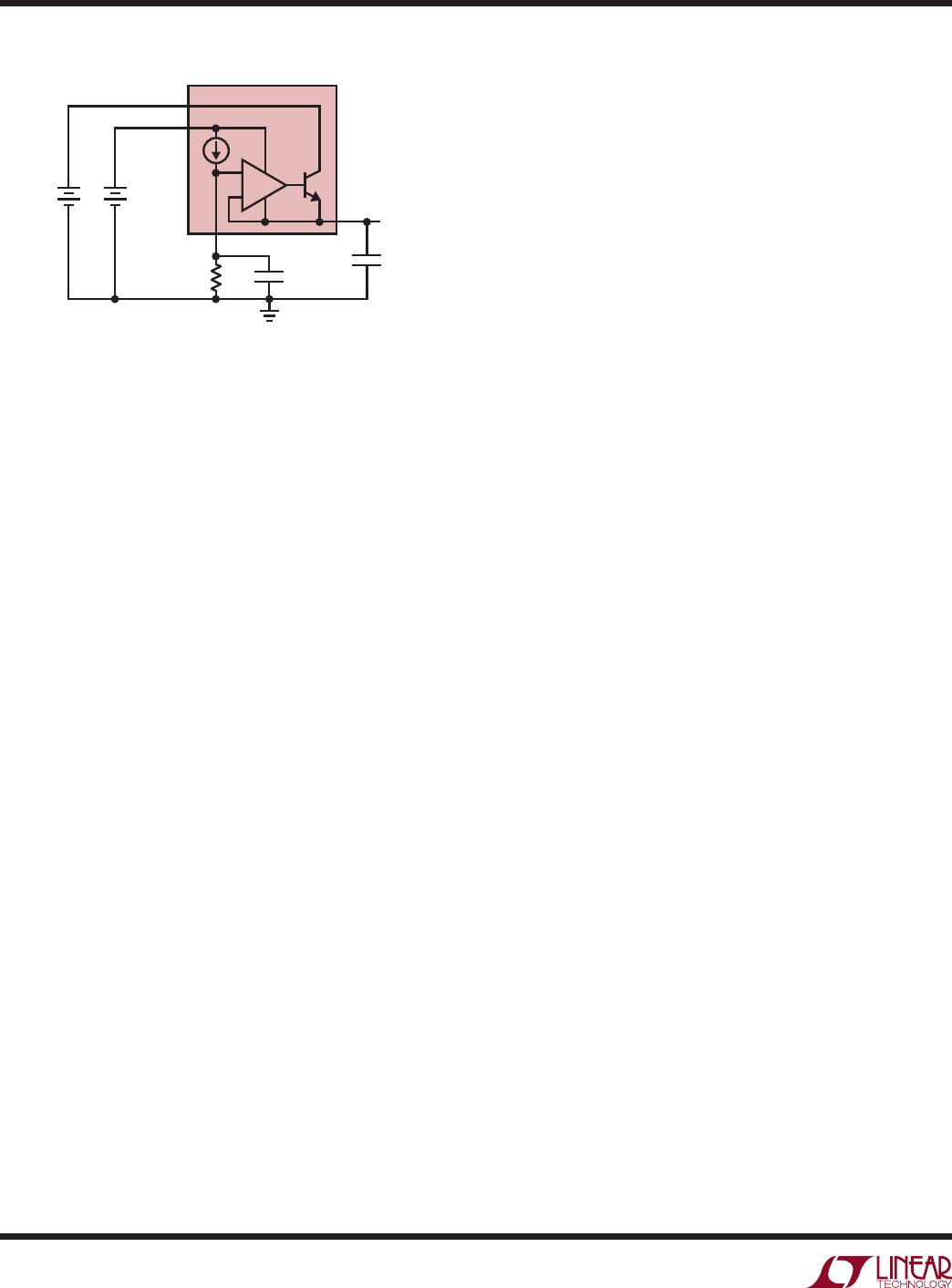

Figure 1. Basic Adjustable Regulator

+

–

LT3080

IN

V

CONTROL

V

CONTROL

OUT

3080 F01

SET

C

OUT

R

SET

V

OUT

C

SET

+

V

IN

+

Output Voltage

The LT3080 generates a 10µA reference current that flows

out of the SET pin. Connecting a resistor from SET to

ground generates a voltage that becomes the reference

point for the error amplifier (see Figure 1). The reference

voltage is a straight

multiplication of the SET pin current

and the value of the resistor. Any voltage can be generated

and there is no minimum output voltage for the regulator.

A minimum load current of 1mA is required to maintain

regulation regardless of output voltage. For true zero

voltage output operation, this 1mA load current must be

returned to a negative supply voltage.

With the low level current used to generate the reference

voltage, leakage paths to or from the SET pin can create

errors in the reference and output voltages. High quality

insulation should be used (e.g., Teflon, Kel-F); cleaning

of all insulating surfaces to remove fluxes and other resi-

dues will probably be required. Surface coating may be

necessary to provide a moisture barrier in high humidity

environments.

Board leakage can be minimized by encircling the SET

pin and circuitry with a guard ring operated at a potential

close to itself; the guard ring should be tied to the OUT

pin. Guarding both sides of the circuit board is required.

Bulk leakage reduction depends on the guard ring width.

Ten nanoamperes of leakage into or out of the SET pin and

associated circuitry creates a 0.1% error in the reference

voltage. Leakages of this magnitude, coupled with other

sources of leakage, can cause significant offset voltage

and reference drift, especially over the possible operating

temperature range.

If guardring techniques are used, this bootstraps any

stray capacitance at the SET pin. Since the SET pin is

a high impedance node, unwanted signals may couple

into the SET pin and cause erratic behavior. This will

be most noticeable when operating with minimum

output capacitors at full load current. The easiest way

to remedy this is to bypass the SET pin with a small

amount of capacitance from SET to ground, 10pF to

20pF is sufficient.

Stability and Output Capacitance

The LT3080 requires an output capacitor for stability. It

is designed to be stable with most low ESR capacitors

(typically ceramic, tantalum or low ESR electrolytic).

A minimum output capacitor of 2.2µF with an ESR of 0.5Ω

or less is recommended to prevent oscillations.

Larger

values of output capacitance decrease peak

deviations

and provide improved transient response for larger load

current changes. Bypass capacitors, used to decouple

individual components powered by the LT3080, increase

the effective output capacitor value.

For improvement in transient performance, place a capaci-

tor across the voltage setting resistor. Capacitors up to

1µF can be used. This bypass capacitor reduces system

noise as well, but start-up time is proportional to the time

constant of the voltage setting resistor (R

SET

in Figure 1)

and SET pin bypass capacitor.

Extra consideration must be given to the use of ceramic

capacitors. Ceramic capacitors are manufactured with a

variety of dielectrics, each with different behavior across

temperature and applied voltage. The most common

dielectrics used are specified with EIA temperature char-

acteristic codes of Z5U, Y5V, X5R and X7R. The Z5U and

Y5V dielectrics are good for providing high capacitances

in a small package, but they tend to have strong volt-

age and temperature coefficients as shown in Figures 2

and 3. When used with a 5V regulator, a 16V 10µF Y5V

capacitor can exhibit an effective value as low as 1µF to

2µF for the DC bias voltage applied and over the operating

temperature range. The X5R and X7R dielectrics result in

more stable characteristics and are more suitable for use

as the output capacitor. The X7R type has better stability

across temperature, while the X5R is less expensive and is

applicaTions inForMaTion