OP275

–8–

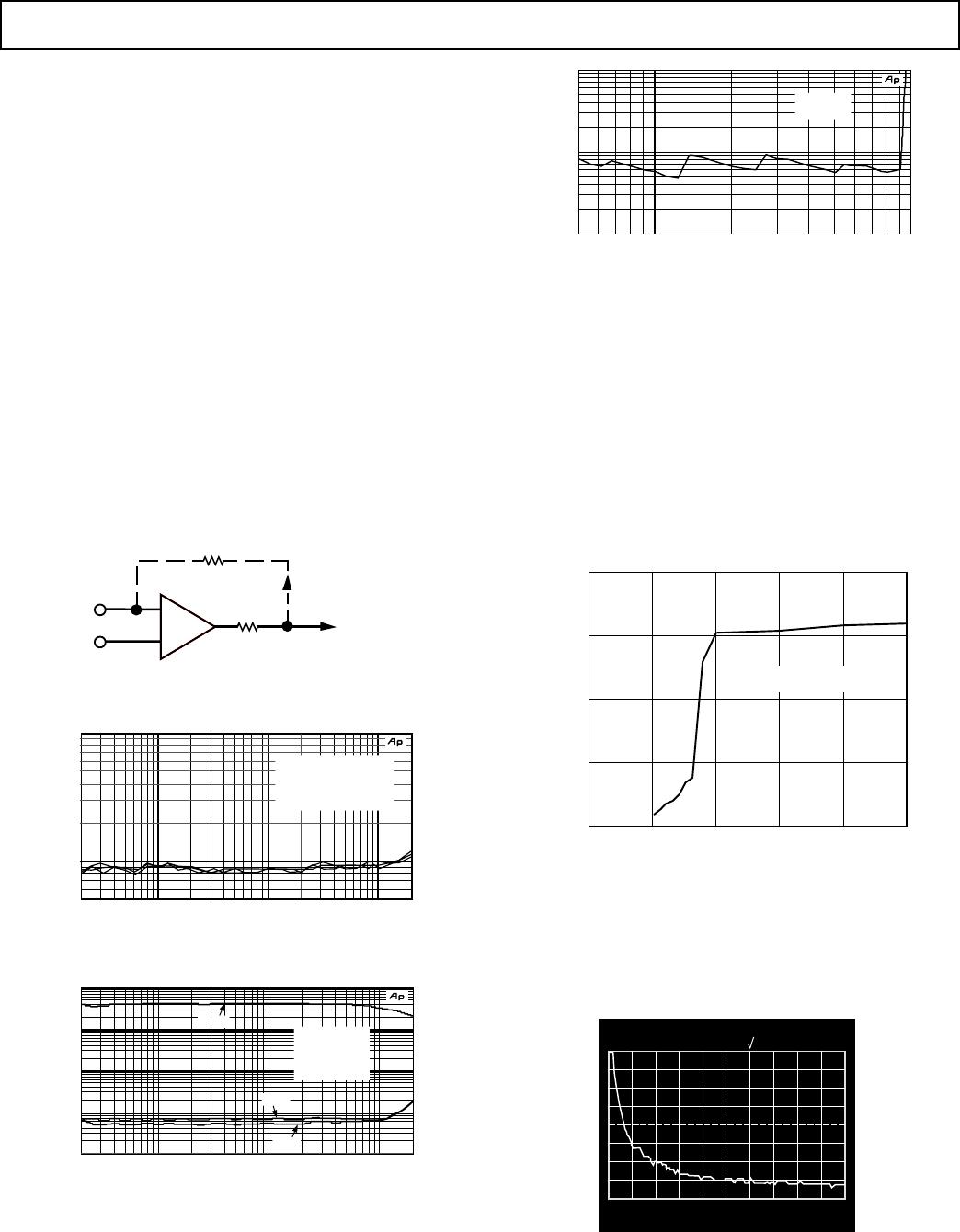

Noise Testing

For audio applications, the noise density is usually the most

important noise parameter. For characterization, the OP275 is

tested using an Audio Precision, System One. The input signal

to the Audio Precision must be amplied enough to measure it

accurately. For the OP275, the noise is gained by approximately

1020 using the circuit shown in Figure 7. Any readings on the

Audio Precision must then be divided by the gain. In imple-

menting this test xture, good supply bypassing is essential.

A

B

OP275

909

100

OP37

909

100

909

100

OP37

4.42k

490

OUTPUT

Figure 7. Noise Test Fixture

Input Overcurrent Protection

The maximum input differential voltage that can be applied

to the OP275 is determined by a pair of internal Zener diodes

connected across its inputs. They limit the maximum differential

input voltage to ±7.5 V. This is to prevent emitter-base junction

breakdown from occurring in the input stage of the OP275 when

very large differential voltages are applied. However, to preserve

the OP275’s low input noise voltage, internal resistances in series

with the inputs were not used to limit the current in the clamp

diodes. In small signal applications, this is not an issue; however,

in applications where large differential voltages can be inadvert-

ently applied to the device, large transient currents can ow

through these diodes. Although these diodes have been designed

to carry a current of ±5 mA, external resistors as shown in Figure 8

should be used in the event that the OP275’s differential voltage

were to exceed ±7.5 V.

OP275

1.4k

1.4k

–

+

2

3

6

Figure 8. Input Overcurrent Protection

Output Voltage Phase Reversal

Since the OP275’s input stage combines bipolar transistors for

low noise and p-channel JFETs for high speed performance, the

output voltage of the OP275 may exhibit phase reversal if either

of its inputs exceeds its negative common-mode input voltage.

This might occur in very severe industrial applications where

a sensor or system fault might apply very large voltages on the

inputs of the OP275. Even though the input voltage range of the

OP275 is ±10.5 V, an input voltage of approximately –13.5 V will

cause output voltage phase reversal. In inverting amplier con-

gurations, the OP275’s internal 7.5 V input clamping diodes will

prevent phase reversal; however, they will not prevent this effect

from occurring in noninverting applications. For these applications,

the x is a simple one and is illustrated in Figure 9. A 3.92 k

resistor in series with the noninverting input of the OP275 cures

the problem.

R

FB

*

V

IN

R

S

3.92k

V

OUT

R

L

2k

*

R

FB

IS OPTIONAL

–

+

Figure 9. Output Voltage Phase Reversal Fix

Overload or Overdrive Recovery

Overload or overdrive recovery time of an operational amplier

is the time required for the output voltage to recover to a rated

output voltage from a saturated condition. This recovery time

is important in applications where the amplier must recover

quickly after a large abnormal transient event. The circuit shown

in Figure 10 was used to evaluate the OP275’s overload recovery

time. The OP275 takes approximately 1.2 ms to recover to V

OUT

=

+10 V and approximately 1.5 µs to recover to V

OUT

= –10 V.

V

IN

V

OUT

R

L

2.43k

A1 = 1/2 OP275

R2

10k

R1

1k

4V p-p

@100Hz

1

2

3

A1

R

S

909k

–

+

Figure 10. Overload Recovery Time Test Circuit

Measuring Settling Time

The design of OP275 combines a high slew rate and a wide gain

bandwidth product to produce a fast settling (t

S

< 1 µs) amplier

for 8- and 12-bit applications. The test circuit designed to mea-

sure the settling time of the OP275 is shown in Figure 11. This

test method has advantages over false-sum node techniques in

that the actual output of the amplier is measured, instead of an

error voltage at the sum node. Common-mode settling effects are

exercised in this circuit in addition to the slew rate and band-

width effects measured by the false-sum node method. Of course,

a reasonably at-top pulse is required as the stimulus.

The output waveform of the OP275 under test is clamped by

Schottky diodes and buffered by the JFET source follower.

The signal is amplied by a factor of 10 by the OP260 and

then Schottky-clamped at the output to prevent overloading the

oscilloscope’s input amplier. The OP41 is congured as a fast

integrator, which provides overall dc offset nulling.

High Speed Operation

As with most high speed ampliers, care should be taken with

supply decoupling, lead dress, and component placement.

Recommended circuit congurations for inverting and nonin-

verting applications are shown in Figures 12 and 13.

REV. C