AD811 Data Sheet

APPLICATIONS INFORMATION

GENERAL DESIGN CONSIDERATIONS

The AD811 is a current feedback amplifier optimized for use in

high performance video and data acquisition applications.

Because it uses a current feedback architecture, its closed-loop

−3 dB bandwidth is dependent on the magnitude of the

feedback resistor. The desired closed-loop gain and bandwidth

are obtained by varying the feedback resistor (R

FB

) to tune the

bandwidth and by varying the gain resistor (R

G

) to obtain the

correct gain. Table 3 contains recommended resistor values for

a variety of useful closed-loop gains and supply voltages.

Table 3. −3 dB Bandwidth vs. Closed-Loop Gain and

Resistance Values

V

S

= ±15 V

Closed-Loop Gain R

FB

R

G

−3 dB BW (MHz)

+1 750 Ω 140

+2 649 Ω 649 Ω 120

+10 511 Ω 56.2 Ω 100

−1

590 Ω 590 Ω 115

−10 511 Ω 51.1 Ω 95

V

S

= ±5 V

Closed-Loop Gain R

FB

R

G

−3 dB BW (MHz)

+1 619 Ω 80

+2 562 Ω 562 Ω 80

+10 442 Ω 48.7 Ω 65

−1

562 Ω 562 Ω 75

−10

442 Ω 44.2 Ω 65

V

S

= ±10 V

Closed-Loop Gain R

FB

R

G

−3 dB BW (MHz)

+1 649 Ω 105

+2 590 Ω 590 Ω 105

+10 499 Ω 49.9 Ω 80

−1 590 Ω 590 Ω 105

−10 499 Ω 49.9 Ω 80

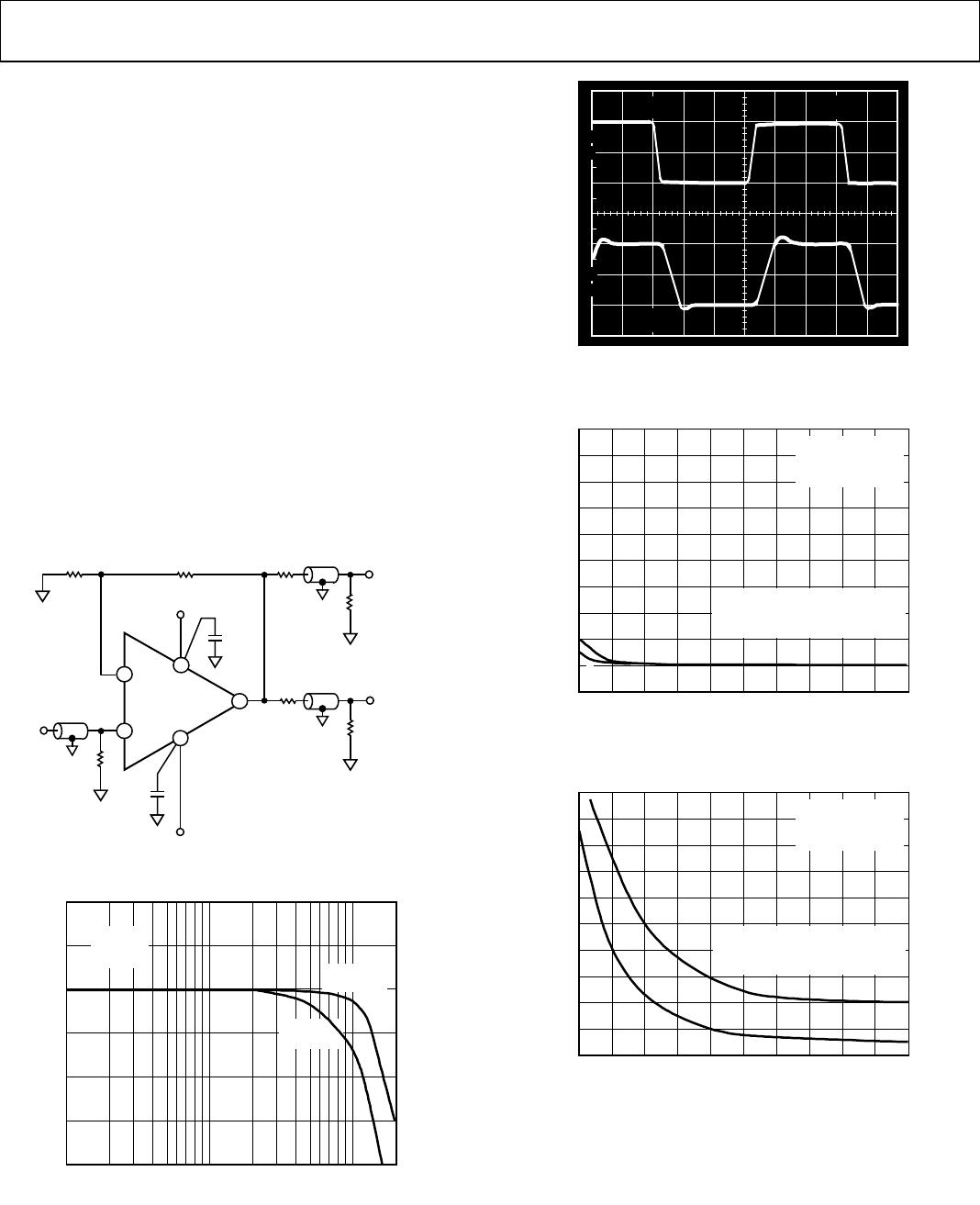

Figure 17 and Figure 18 illustrate the relationship between the

feedback resistor and the frequency and time domain response

characteristics for a closed-loop gain of +2. (The response at

other gains is similar.)

The 3 dB bandwidth is somewhat dependent on the power

supply voltage. As the supply voltage is decreased, for example,

the magnitude of the internal junction capacitances is increased,

causing a reduction in closed-loop bandwidth. To compensate

for this, smaller values of feedback resistor are used at lower

supply voltages.

ACHIEVING THE FLATTEST GAIN RESPONSE AT

HIGH FREQUENCY

Achieving and maintaining gain flatness of better than 0.1 dB at

frequencies above 10 MHz requires careful consideration of

several issues.

Choice of Feedback and Gain Resistors

Because of the previously mentioned relationship between the

3 dB bandwidth and the feedback resistor, the fine scale gain

flatness varies, to some extent, with feedback resistor tolerance.

Therefore, it is recommended that resistors with a 1% tolerance

be used if it is desired to maintain flatness over a wide range of

production lots. In addition, resistors of different construction

have different associated parasitic capacitance and inductance.

Metal film resistors were used for the bulk of the character-

ization for this data sheet. It is possible that values other than

those indicated are optimal for other resistor types.

Printed Circuit Board Layout Considerations

As is expected for a wideband amplifier, PC board parasitics can

affect the overall closed-loop performance. Of concern are stray

capacitances at the output and the inverting input nodes. If a

ground plane is used on the same side of the board as the signal

traces, a space (3/16" is plenty) should be left around the signal

lines to minimize coupling. Additionally, signal lines connecting

the feedback and gain resistors should be short enough so that

their associated inductance does not cause high frequency gain

errors. Line lengths less than 1/4" are recommended.

Quality of Coaxial Cable

Optimum flatness when driving a coax cable is possible only

when the driven cable is terminated at each end with a resistor

matching its characteristic impedance. If the coax is ideal, then

the resulting flatness is not affected by the length of the cable.

While outstanding results can be achieved using inexpensive

cables, note that some variation in flatness due to varying cable

lengths may occur.

Power Supply Bypassing

Adequate power supply bypassing can be critical when optimiz-

ing the performance of a high frequency circuit. Inductance in

the power supply leads can form resonant circuits that produce

peaking in the amplifier’s response. In addition, if large current

transients must be delivered to the load, then bypass capacitors

(typically greater than 1 µF) are required to provide the best

settling time and lowest distortion. Although the recommended

0.1 µF power supply bypass capacitors are sufficient in many

applications, more elaborate bypassing (such as using two

paralleled capacitors) may be required in some cases.

Rev. G | Page 12 of 20