2008-2015 Microchip Technology Inc. DS80000425P-page 9

PIC18F24K20/25K20/44K20/45K20

30. Module: ECCP

ECCP – In Full-Bridge mode when PR2 =

CCPR1L and DC1B[1:0] <>‘00’ and the direction

is changed, then the dead time before the modu-

lated output starts is compromised. The modulated

signal improperly starts immediately with the direc-

tion change and stays on for T

OSC *TMR2

Prescale * DC1B[1:0].

Work around

Avoid changing direction when the duty cycle is

within three Least Significant steps of 100% duty

cycle. Instead, clear the DC1B[1:0] bits before the

direction change and then set them to the desired

value after the direction change is complete.

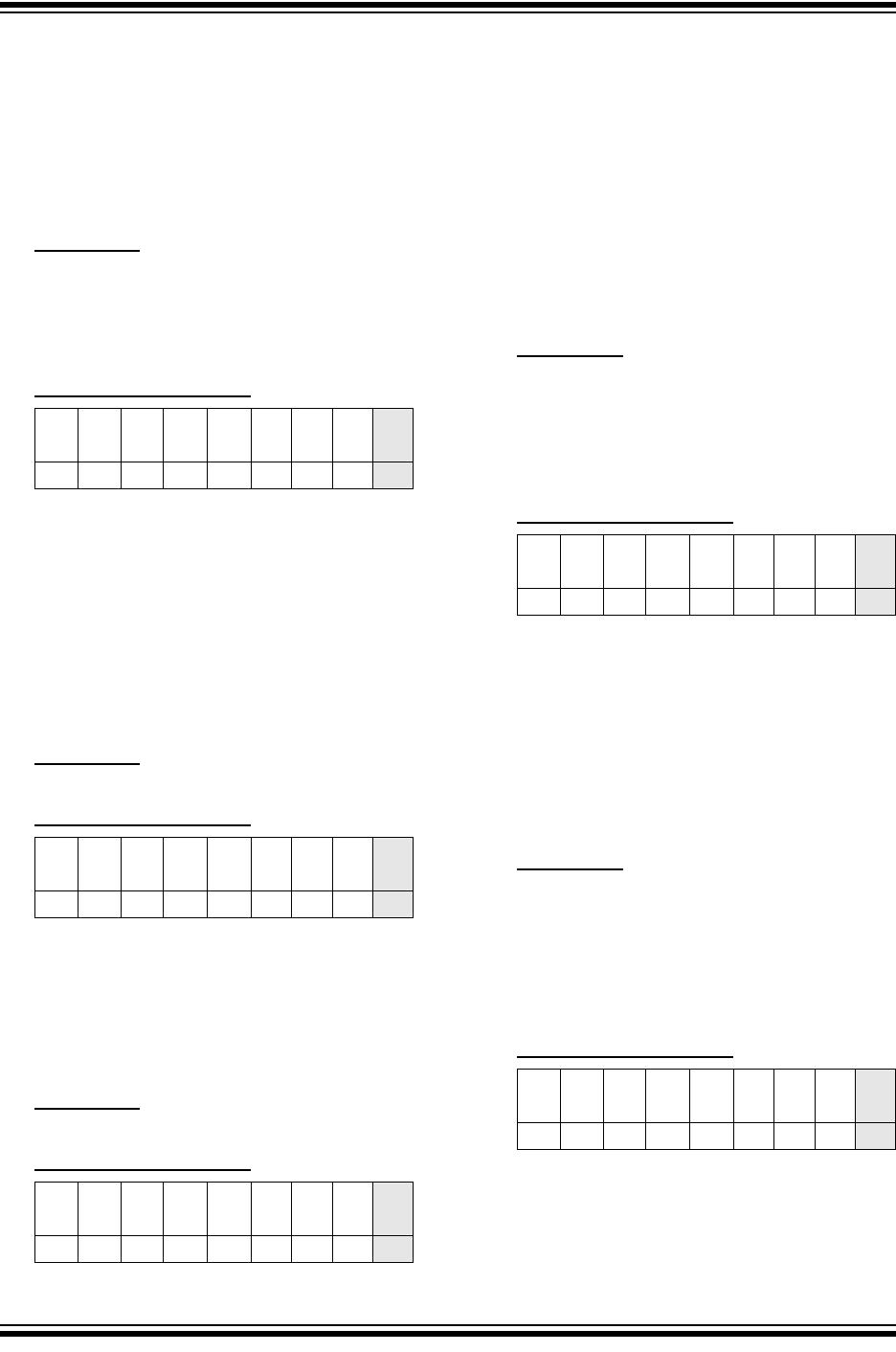

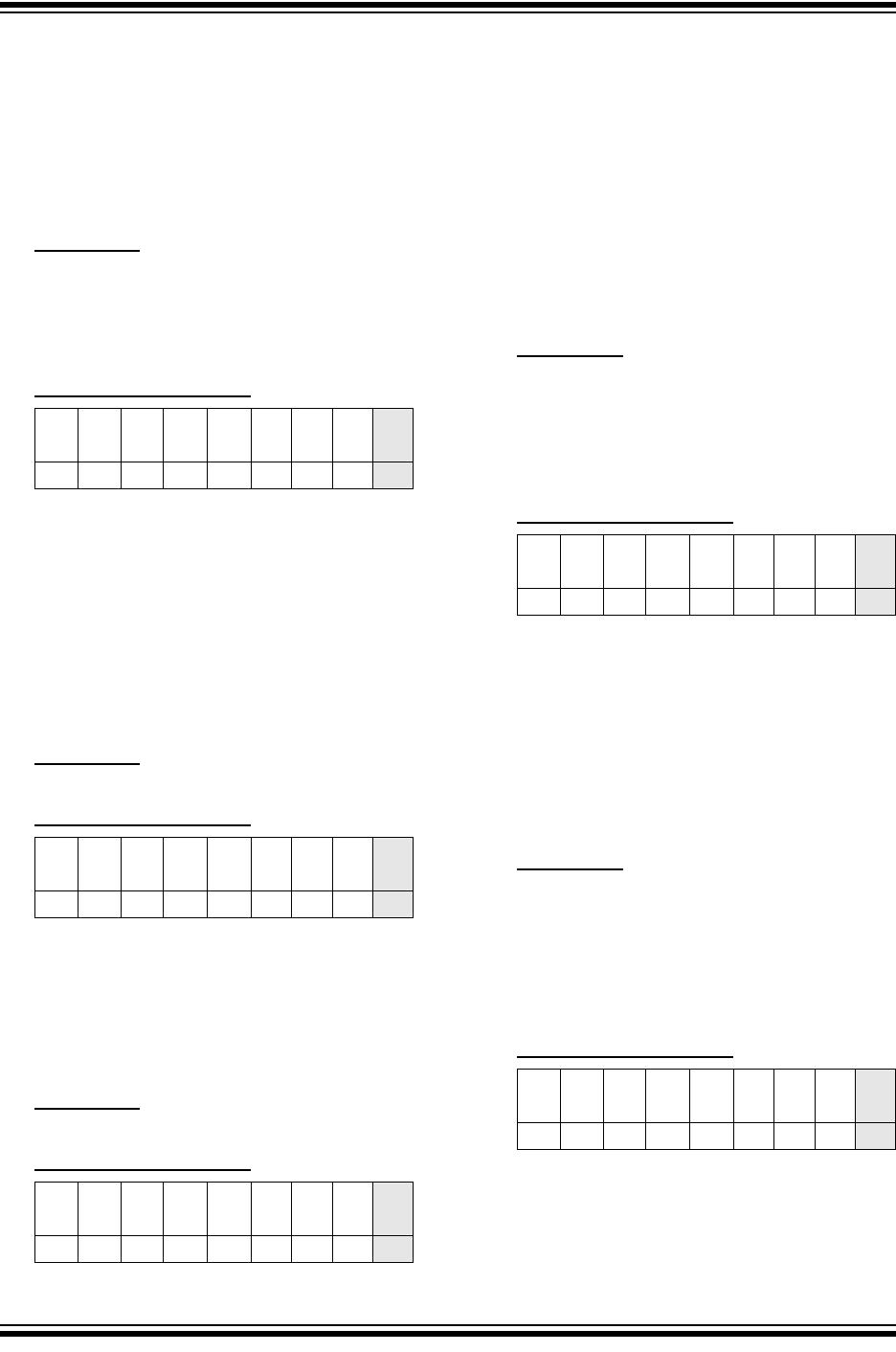

Affected Silicon Revisions

31. Module: MSSP SPI

When the SPI clock is configured for Timer2/2

(SSPCON1<3:0> = 0011) and the CKE bit of the

SSPSTAT register is ‘1’, then when SSPBUF is

written, the SCK output is improperly immediately

driven to the non-Idle state together with the MSb

value of the SSPBUF. The duration at which SDO

and SCK remain at these levels may be shorter

than a full half-bit period. The remaining bits in the

byte are output properly.

Work around

None.

Affected Silicon Revisions

32. Module: MSSP SPI

In SPI Master mode, when the CKE bit of the

SSPSTAT register is cleared and the SMP bit of

the SSPSTAT register is set, then the last bit of the

incoming data stream (bit 0) at the SDI pin will not

be sampled properly.

Work around

None.

Affected Silicon Revisions

33. Module: MSSP SPI

In SPI Master mode, if the SSPBUF register is

written while a byte is actively being transmitted,

an extra clock pulse will be improperly generated

at the end of the transmission. Further writes to the

SSPBUF register will be inhibited although 8 or 9

clock pulses will be generated for each attempted

write. The WCON bit of the SSPCON register is

properly set indicating that a write collision

occurred. However, the write collision condition

can only be cleared by resetting the MSSP

module. Clear the MSSP by clearing the SSPEN

bit of the SSPCON1 register.

Work around

Use the SSPIF bit of the PIR1 register or the BF bit

of the SSPSTAT register to determine that the

transmission is complete before writing the

SSPBUF register. In the event that a write collision

does occur, use the slave select feature to

resynchronize the slave clock.

Affected Silicon Revisions

34. Module: MSSP I

2

C

In Master I

2

C Receive mode if a Stop condition

occurs in the middle of an address or data

reception, then the SCL clock stream will continue

endlessly and the RCEN bit of the SSPCON2

register will remain set improperly. If a Start

condition occurs after the improper Stop condition

then nine additional clocks will be generated

followed by the RCEN bit going low.

Work around

Use low-impedance pull-ups on the SDA line to

reduce the possibility of noise glitches which may

trigger an improper Stop event. Use a time-out

event timer to detect the unexpected Stop

condition and resulting stuck RCEN bit. Clear the

stuck RCEN bit by clearing the SSPEN bit of

SSPCON1.

Affected Silicon Revisions

0xA

0xC

0xE

0x11

0x16

0x18

0x19

0x1B

0x1C

XXXXXXXXX

0xA

0xC

0xE

0x11

0x16

0x18

0x19

0x1B

0x1C

XXXXXXXXX

0xA

0xC

0xE

0x11

0x16

0x18

0x19

0x1B

0x1C

XXXXXXXXX

0xA

0xC

0xE

0x11

0x16

0x18

0x19

0x1B

0x1C

XXXXXXXXX

0xA

0xC

0xE

0x11

0x16

0x18

0x19

0x1B

0x1C

XXXXXXXXX