4

FN8168.6

December 15, 2011

Clock and Data Conventions

Data states on the SDA line can change only during SCL

LOW periods (t

LOW

). SDA state changes during SCL HIGH

are reserved for indicating start and stop conditions.

Start Condition

All commands to the X9258 are preceded by the start

condition, which is a HIGH to LOW transition of SDA while

SCL is HIGH (t

HIGH

). The X9258 continuously monitors the

SDA and SCL lines for the start condition and will not

respond to any command until this condition is met.

Stop Condition

All communications must be terminated by a stop condition,

which is a LOW to HIGH transition of SDA while SCL is

HIGH.

Acknowledge

Acknowledge is a software convention used to provide a

positive handshake between the master and slave devices

on the bus to indicate the successful receipt of data. The

transmitting device, either the master or the slave, will

release the SDA bus after transmitting 8 bits. The master

generates a ninth clock cycle and during this period the

receiver pulls the SDA line LOW to acknowledge that it

successfully received the 8 bits of data.

The X9258 will respond with an acknowledge after

recognition of a start condition and its slave address and

once again after successful receipt of the command byte. If

the command is followed by a data byte, the X9258 will

respond with a final acknowledge.

Array Description

The X9258 is comprised of four resistor arrays. Each array

contains 255 discrete resistive segments that are connected

in series. The physical ends of each array are equivalent to

the fixed terminals of a mechanical potentiometer (V

H

/R

H

and V

L

/R

L

inputs).

At both ends of each array and between each resistor

segment is a CMOS switch connected to the wiper (V

W

)

output. Within each individual array only one switch may be

turned on at a time. These switches are controlled by the

Wiper Counter Register (WCR). The 8 bits of the WCR are

decoded to select, and enable, one of 256 switches.

The WCR may be written directly, or it can be changed by

transferring the contents of one of four associated data

registers into the WCR. These data registers and the WCR

can be read and written by the host system.

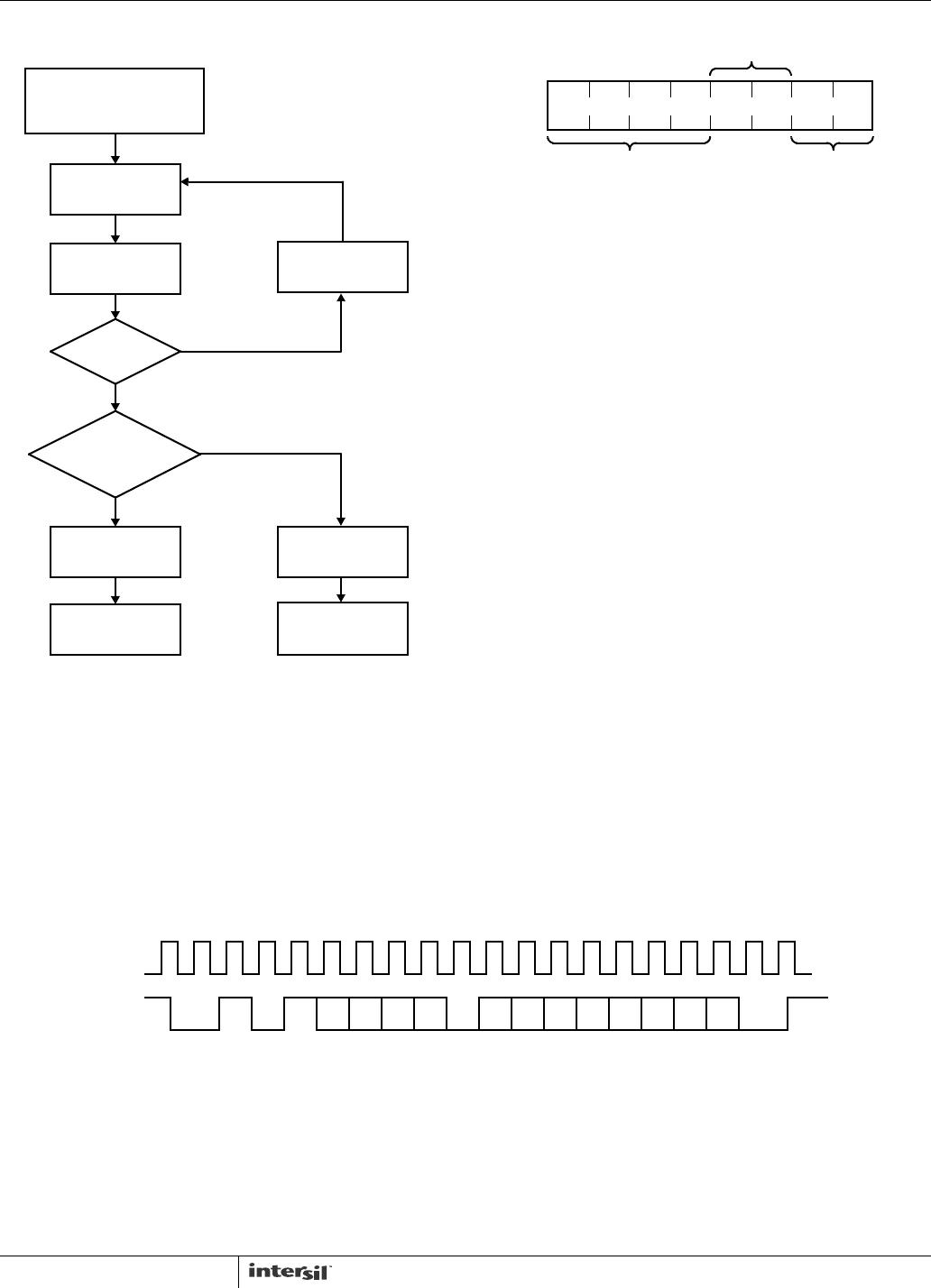

Device Addressing

Following a start condition the master must output the

address of the slave it is accessing. The most significant

4 bits of the slave address are the device type identifier

(refer to Figure 1). For the X9258 this is fixed as 0101[B].

The next 4 bits of the slave address are the device address.

The physical device address is defined by the state of the A0

thru A3 inputs. The X9258 compares the serial data stream

with the address input state; a successful compare of all

4 address bits is required for the X9258 to respond with an

acknowledge. The A

0

thru A

3

inputs can be actively driven

by CMOS input signals or tied to V

CC

or V

SS

.

Acknowledge Polling

The disabling of the inputs (during the internal nonvolatile

write operation), can be used to take advantage of the

typical 5ms nonvolatile write cycle time. Once the stop

condition is issued to indicate the end of the nonvolatile write

command, the X9258 initiates the internal write cycle. ACK

polling can be initiated immediately. This involves issuing the

start condition followed by the device slave address. If the

X9258 is still busy with the write operation, no ACK will be

returned. If the X9258 has completed the write operation an

ACK will be returned and the master can then proceed with

the next operation.

100

A3 A2 A1 A0

DEVICE TYPE

IDENTIFIER

DEVICE ADDRESS

1

FIGURE 1. SLAVE ADDRESS

X9258