Full-Bridge PWM Motor Driver

A4973

6

Allegro MicroSystems, LLC

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

The operation of the circuit is as follows: when the PWM latch is

reset by the current comparator, the voltage on the RC terminal

will begin to decay from approximately 0.60V

CC

. When the

voltage on the RC terminal reaches approximately 0.22V

CC

, the

PWM latch is set, thereby enabling the driver(s).

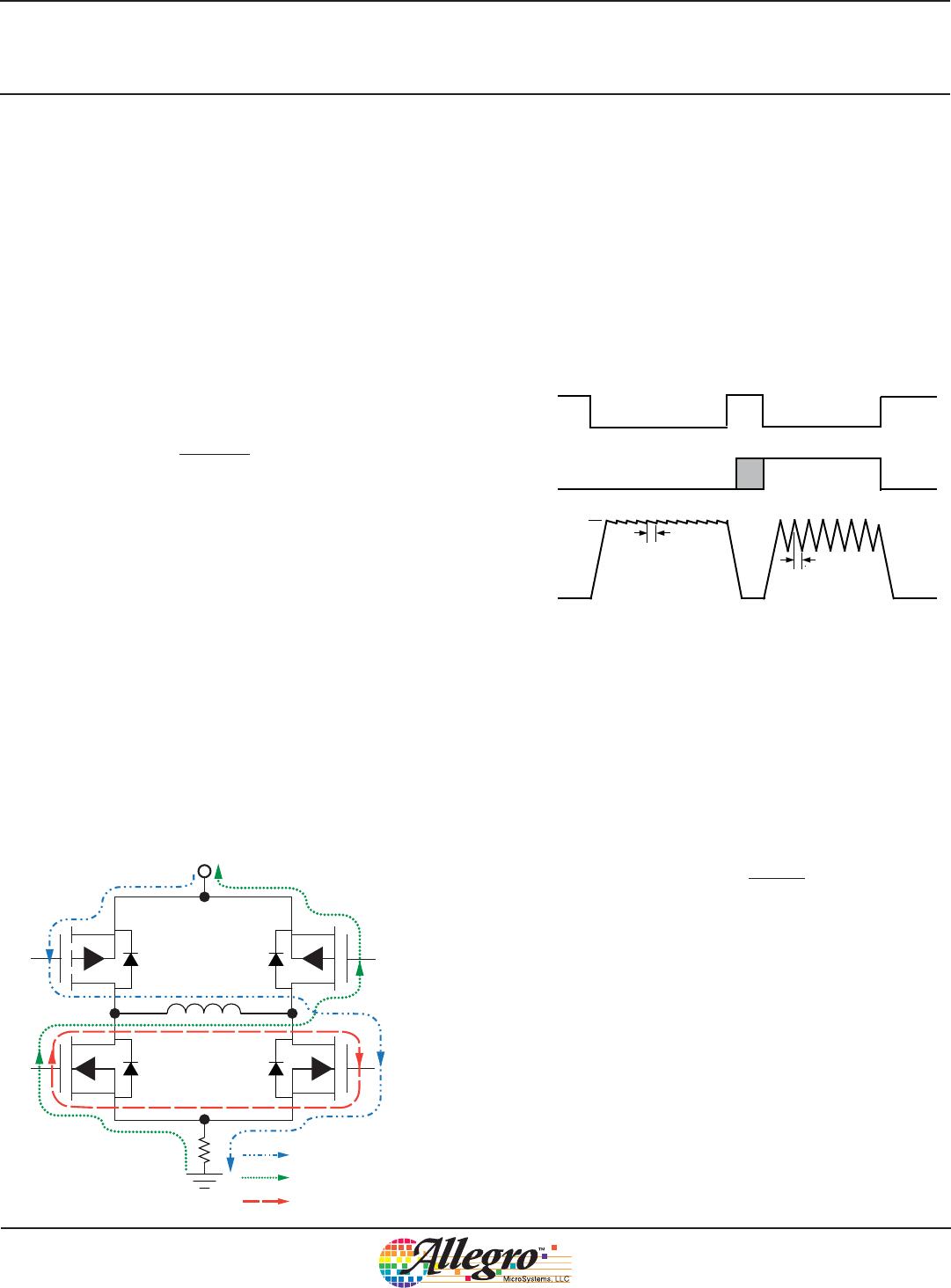

RC Blanking. In addition to determining the fixed off-time of

the PWM control circuit, the C

T

component sets the comparator

blanking time. This function blanks the output of the comparator

when the outputs are switched by the internal current-control

circuitry (or by the PHASE, BRAKE, or ENABLE inputs).

The comparator output is blanked to prevent false over-current

detections due to reverse recovery currents of the clamp diodes,

and/or switching transients related to distributed capacitance in

the load.

During internal PWM operation, at the end of the t

OFF

time, the

comparator’s output is blanked and C

T

begins to be charged

from approximately 0.22V

CC

by an internal current source of

approximately 1 mA. The comparator output remains blanked

until the voltage on C

T

reaches approximately 0.60V

CC

.

When a transition of the PHASE input occurs, C

T

is discharged

to near ground during the crossover delay time (the crossover

delay time is present to prevent simultaneous conduction of

the source and sink drivers). After the crossover delay, C

T

is

charged by an internal current source of approximately 1 mA.

The comparator output remains blanked until the voltage on C

T

reaches approximately 0.60V

CC

.

When the device is disabled, via the ENABLE input, C

T

is

discharged to near ground. When the device is re-enabled, C

T

is

charged by an internal current source of approximately 1 mA.

The comparator output remains blanked until the voltage on C

T

reaches approximately 0.60V

CC

.

For 3.3 V operation, the minimum recommended value

for C

T

is 680 pF ± 5 %. For 5.0 V operation, the minimum

recommended value for C

T

is 470 pF ± 5%. These values

ensure that the blanking time is sufficient to avoid false trips

of the comparator under normal operating conditions. For

optimal regulation of the load current, the above values for C

T

are recommended and the value of R

T

can be sized to determine

t

OFF

. For more information regarding load current regulation, see

below.

LOAD CURRENT REGULATION

WITH INTERNAL PWM

CURRENT-CONTROL CIRCUITRY

When the device is operating in slow current-decay mode,

there is a limit to the lowest level that the PWM current-

control circuitry can regulate load current. The limitation is the

minimum duty cycle, which is a function of the user-selected

value of t

OFF

and the minimum on-time pulse t

ON(min)

max that

occurs each time the PWM latch is reset. If the motor is not

rotating (as in the case of a stepper motor in hold/detent mode, a

brush dc motor when stalled, or at startup), the worst case value

of current regulation can be approximated by:

{ [ V

BB

– (2 × I × R

DS

) ] × t

ON(min)

max } – [1.05 (I × R

DS

+ V

F

) × t

OFF

]

1.05 × (t

ON(min)

max + t

OFF

) × R

LOAD

I

AVE

where t

OFF

= R

T

x C

T

, R

LOAD

is the series resistance of the load,

V

BB

is the motor supply voltage and t

ON(min)

max is specified in

the Electrical Characteristics table. When the motor is rotating,

the back EMF generated will influence the above relationship.

For brush dc motor applications, the current regulation is

improved. For stepper motor applications, when the motor is

rotating, the effect is more complex. A discussion of this subject

is included in the section on stepper motors below.

The following procedure can be used to evaluate the worst-case

slow current-decay internal PWM load current regulation in the

system:

1. Set V

REF

to 0 volts. With the load connected and the PWM

current control operating in slow current-decay mode, use an

oscilloscope to measure the time the output is low (sink on) for

the output that is chopping. This is the typical minimum on time

(t

ON(min)

typ) for the device.

2. The C

T

then should be increased until the measured value

of t

ON(min)

is equal to t

ON(min)

max as specified in the electrical

characteristics table.

3. When the new value of C

T

has been set, the value of R

T

should

be decreased so the value for t

OFF

= R

T

x C

T

(with the artificially

increased value of C

T

) is equal to the nominal design value.

4. The worst-case load-current regulation then can be measured

in the system under operating conditions.