Full-Bridge PWM Motor Driver

A4973

8

Allegro MicroSystems, LLC

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

The current-sensing comparator functions down to ground

allowing the device to be used in microstepping, sinusoidal, and

other varying current-profile applications.

Thermal Considerations. For reliable operation it is

recommended that the maximum junction temperature be kept

below 110°C to 125°C. The junction temperature can be measured

best by attaching a thermocouple to the power tab/batwing of the

device and measuring the tab temperature, T

TAB

. The junction

temperature can then be approximated by using the formula:

T

J

T

TAB

+ I

2

LOAD

× R

DS(on)

x R

JT

The value for R

θJT

is given in the package thermal resistance table

for the appropriate package.

The power dissipation of the batwing packages can be improved

by 20% to 30% by adding a section of printed circuit board

copper (typically 6 to 18 square centimeters) connected to the

batwing terminals of the device.

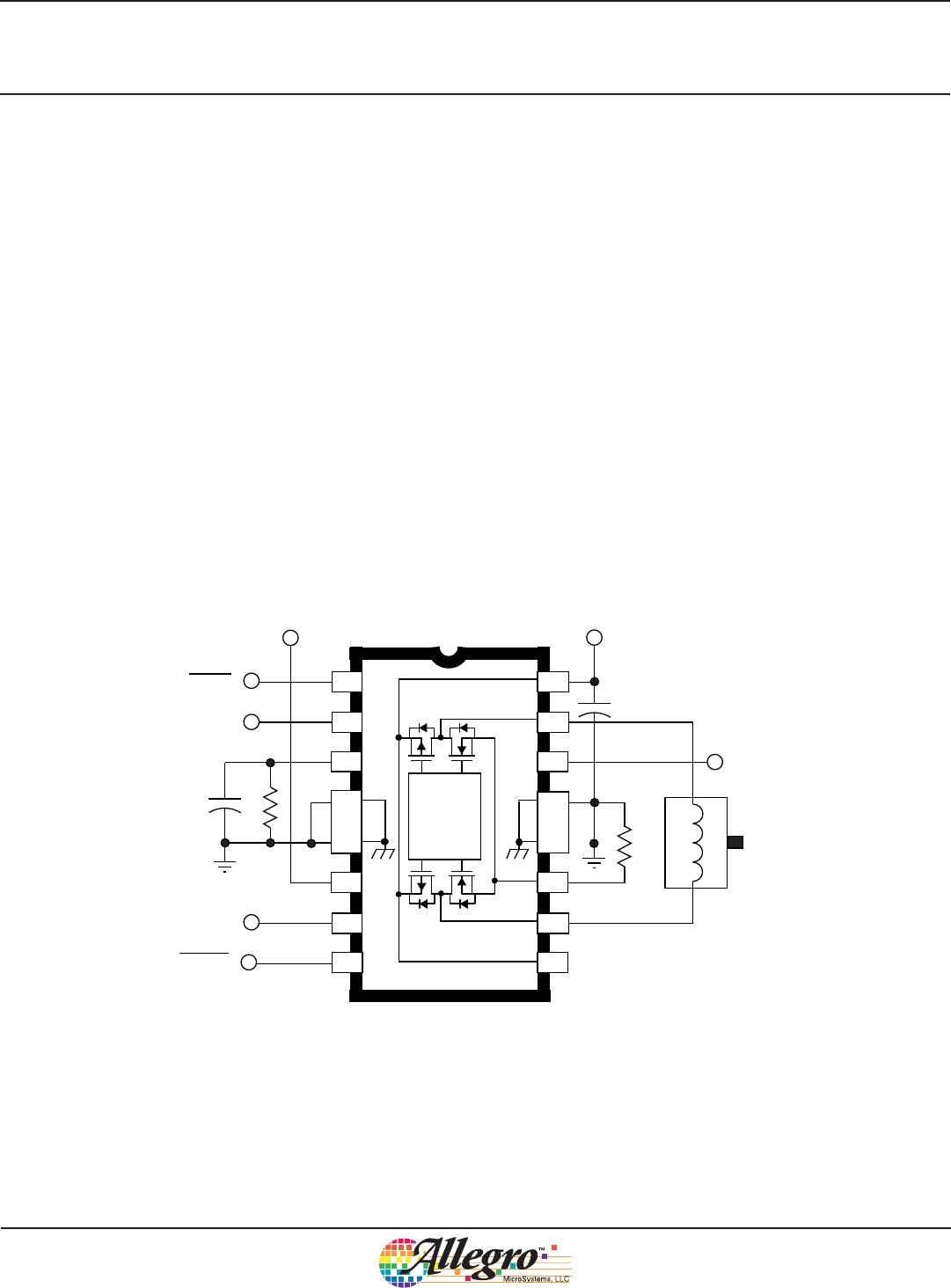

PCB Layout. The load supply terminal, V

BB

, should

be decoupled with an electrolytic capacitor (>47 μF is

recommended) placed as close to the device as is physically

practical. To minimize the effect of system ground I x R drops on

the logic and reference input signals, the system ground should

have a low-resistance return to the motor supply voltage. See also

the Current Sensing and Thermal Considerations sections, above.

Fixed Off-Time Selection. With increasing values of t

OFF,

switching losses will decrease, low-level load-current regulation

will improve, EMI will be reduced, the PWM frequency will

decrease, and ripple current will increase. The value of t

OFF

can

be chosen for optimization of these parameters. For applications

where audible noise is a concern, typical values of t

OFF

are chosen

to be in the range of 15 to 35 μs.

Stepper Motor Applications. The MODE terminal can be

used to optimize the performance of the device in microstepping/

sinusoidal stepper-motor drive applications. When the load

current is increasing, slow decay mode is used to limit the

switching losses in the device and iron losses in the motor. This

also improves the maximum rate at which the load current can

increase (as compared to fast decay) due to the slow rate of decay

during t

OFF

. When the load current is decreasing, fast-decay mode

is used to regulate the load current to the desired level. This

prevents tailing of the current profile caused by the back-EMF

voltage of the stepper motor.

In stepper-motor applications applying a constant current to

the load, slow-decay mode PWM is typically used to limit the

switching losses in the device and iron losses in the motor.

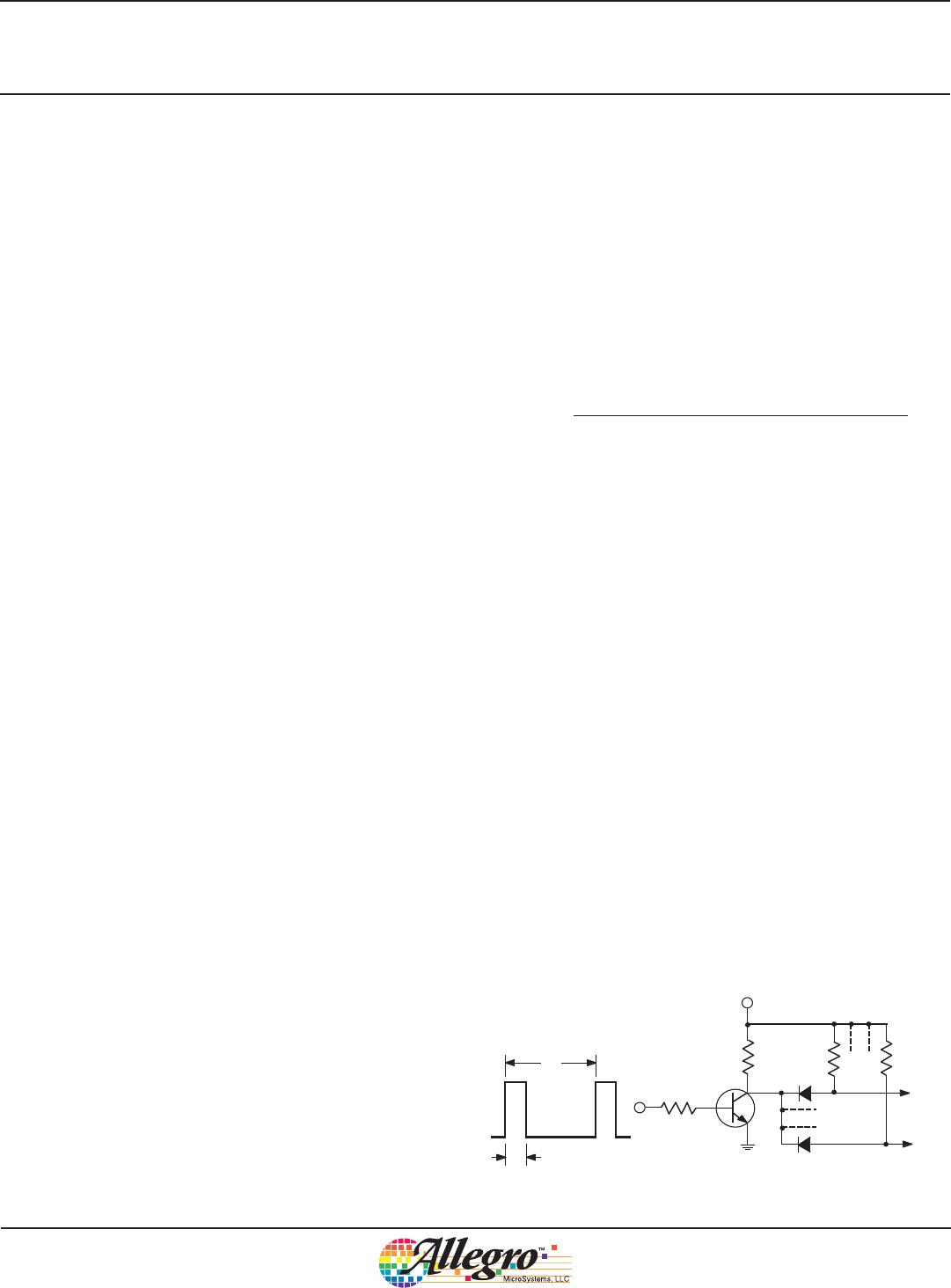

DC Motor Applications. In closed-loop systems, the

speed of a dc motor can be controlled by PWM of the PHASE

or ENABLE inputs, or by varying the reference input voltage

(REF). In digital systems (microprocessor controlled), PWM of

the PHASE or ENABLE input is used typically thus avoiding

the need to generate a variable analog voltage reference. In this

case, a dc voltage on the REF input is used typically to limit the

maximum load current.

In dc servo applications, which require accurate positioning

at low or zero speed, PWM of the PHASE input is selected

typically. This simplifies the servo control loop because the

transfer function between the duty cycle on the PHASE input and

the average voltage applied to the motor is more linear than in the

case of ENABLE PWM control (which produces a discontinuous

current at low current levels).

With bidirectional dc servo motors, the PHASE terminal can be

used for mechanical direction control. Similar to when braking

the motor dynamically, abrupt changes in the direction of a

rotating motor produces a current generated by the back-EMF.

The current generated will depend on the mode of operation. If

the internal current control circuitry is not being used, then the

maximum load current generated can be approximated by I

LOAD

=

(V

BEMF

+ V

BB

)/R

LOAD

where V

BEMF

is proportional to the motor’s

speed. If the internal slow current-decay control circuitry is used,

then the maximum load current generated can be approximated

by I

LOAD

= V

BEMF

/R

LOAD

. For both cases care must be taken to