X9317

8

FN8183.9

November 4, 2014

Submit Document Feedback

Pin Descriptions

R

H

and R

L

The high (R

H

) and low (R

L

) terminals of the X9317 are equivalent

to the fixed terminals of a mechanical potentiometer. The

terminology of R

L

and R

H

references the relative position of the

terminal in relation to wiper movement direction selected by the

U/D

input and not the voltage potential on the terminal.

R

W

R

W

is the wiper terminal and is equivalent to the movable

terminal of a mechanical potentiometer. The position of the

wiper within the array is determined by the control inputs. The

wiper terminal series resistance is typically 200Ω.

Up/Down (U/D)

The U/D input controls the direction of the wiper movement and

whether the counter is incremented or decremented.

Increment (INC)

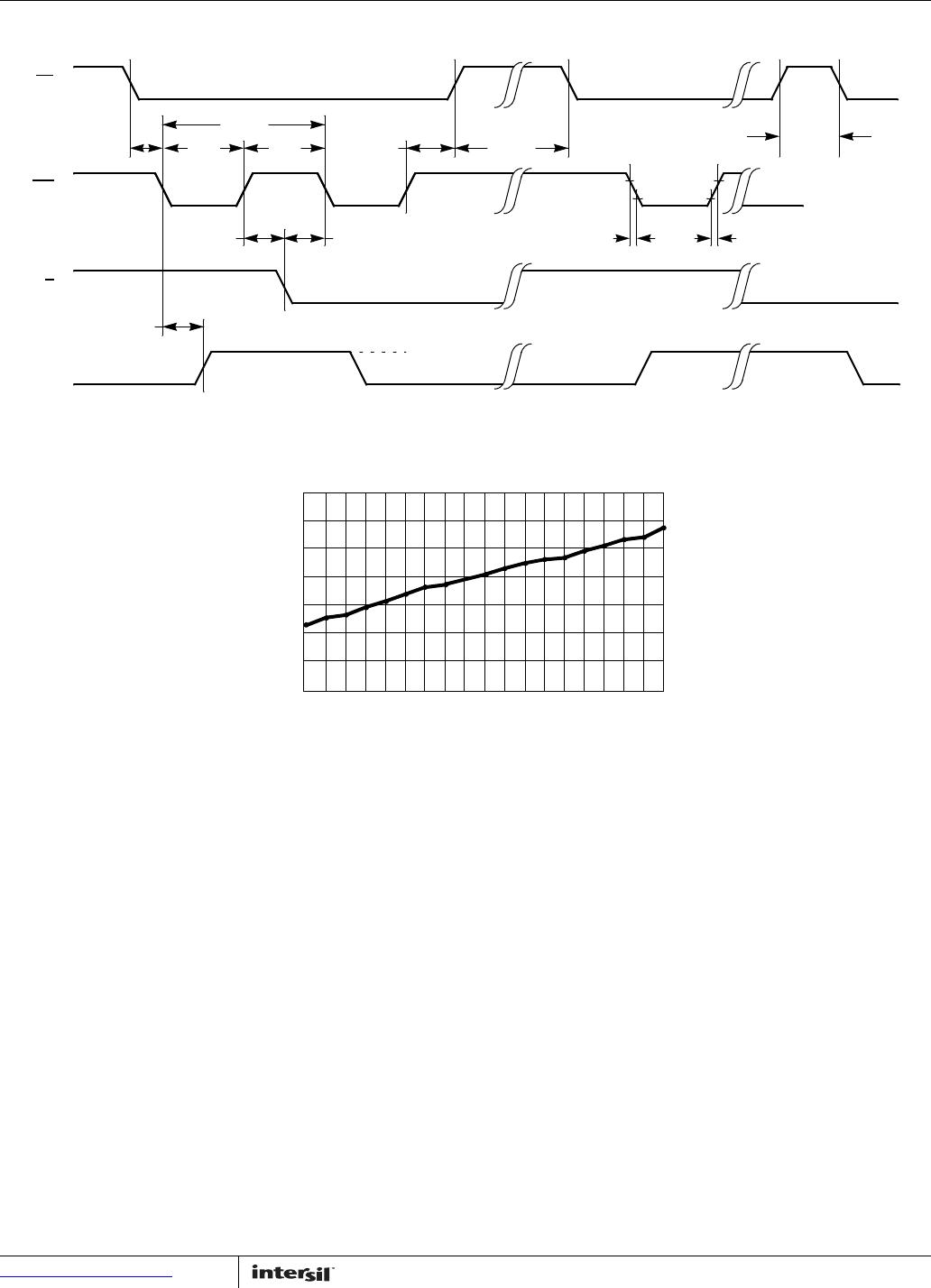

The INC input is negative-edge triggered. Toggling INC will move

the wiper and either increment or decrement the counter in the

direction indicated by the logic level on the U/D

input.

Chip Select (CS)

The device is selected when the CS input is LOW. The current

counter value is stored in nonvolatile memory when CS is

returned HIGH while the INC input is also HIGH. After the store

operation is complete, the X9317 will be placed in the low power

standby mode until the device is selected once again.

Principles of Operation

There are three sections of the X9317: the control section, the

nonvolatile memory, and the resistor array. The control section

operates just like an up/down counter. The output of this counter

is decoded to turn on a single electronic switch connecting a

point on the resistor array to the wiper output. The contents of the

counter can be stored in nonvolatile memory and retained for

future use. The resistor array is comprised of 99 individual

resistors connected in series. Electronic switches at either end of

the array and between each resistor provide an electrical

connection to the wiper pin, R

W

.

The wiper acts like its mechanical equivalent and does not move

beyond the first or last position. That is, the counter does not

wrap around when clocked to either extreme.

The electronic switches on the device operate in a “make before

break” mode when the wiper changes tap positions. If the wiper

is moved several positions, multiple taps are connected to the

wiper for t

IW

(INC to V

W

change). The R

TOTAL

value for the device

can temporarily be reduced by a significant amount if the wiper

is moved several positions.

When the device is powered-down, the last wiper position stored

will be maintained in the nonvolatile memory. When power is

restored, the contents of the memory are recalled and the wiper

is set to the value last stored.

Instructions and Programming

The INC, U/D and CS inputs control the movement of the wiper

along the resistor array. With CS

set LOW, the device is selected

and enabled to respond to the U/D and INC inputs. HIGH-to-LOW

transitions on INC will increment or decrement (depending on the

state of the U/D

input) a 7-bit counter. The output of this counter

is decoded to select one of one hundred wiper positions along

the resistive array.

The value of the counter is stored in nonvolatile memory

whenever CS

transitions HIGH while the INC input is also HIGH.

The system may select the X9317, move the wiper and deselect

the device without having to store the latest wiper position in

nonvolatile memory. After the wiper movement is performed as

previously described and once the new position is reached, the

system must keep INC LOW while taking CS HIGH. The new wiper

position will be maintained until changed by the system or until a

power-up/down cycle recalls the previously stored data.

This procedure allows the system to always power-up to a preset

value stored in nonvolatile memory; then during system

operation minor adjustments could be made. The adjustments

might be based on user preference, system parameter changes

due to temperature drift, etc.

The state of U/D

may be changed while CS remains LOW. This

allows the host system to enable the device and then move the

wiper up and down until the proper trim is attained.

Applications Information

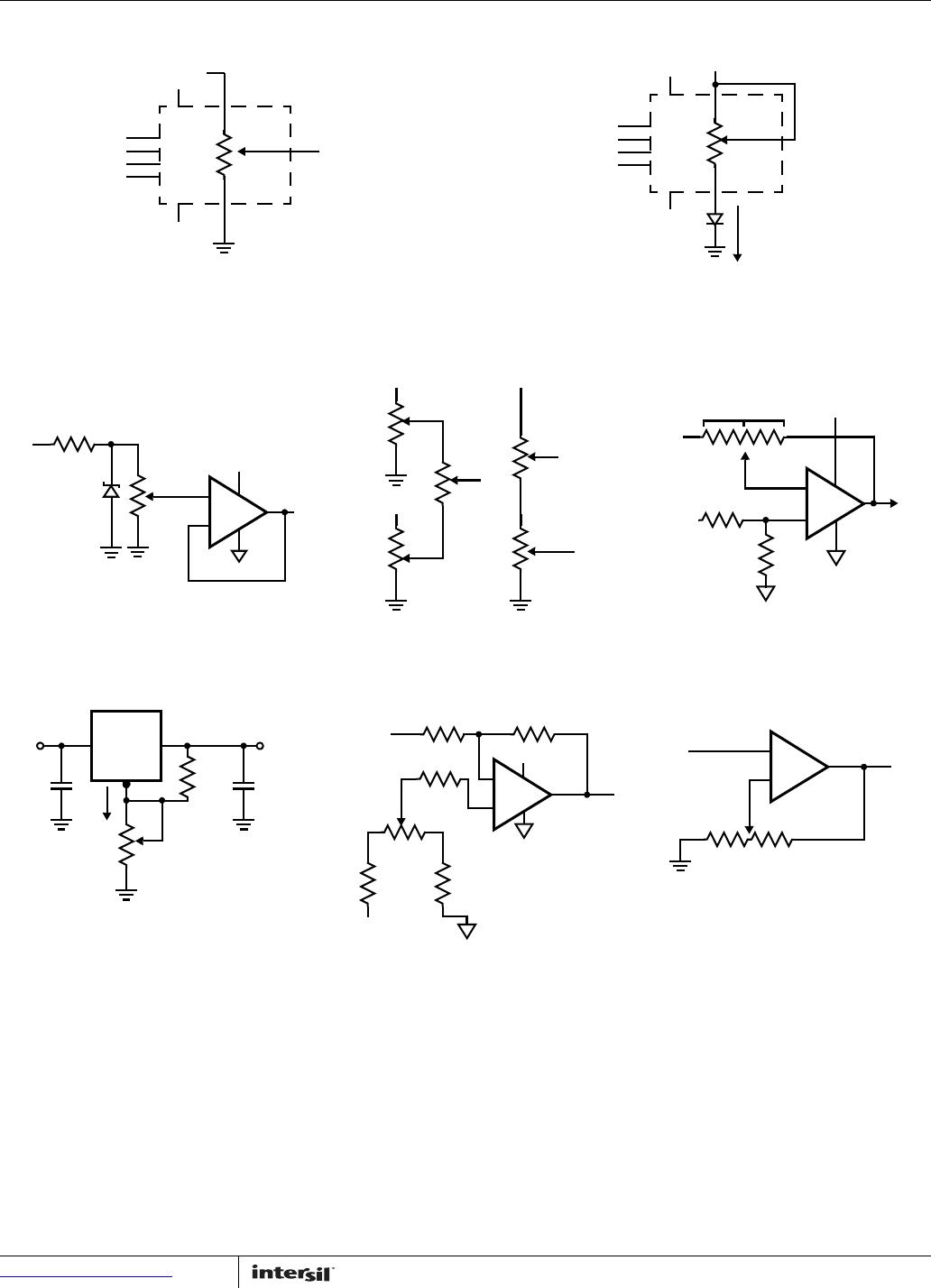

Electronic digitally controlled (XDCP) potentiometers provide

three powerful application advantages:

1. The variability and reliability of a solid-state potentiometer,

2. The flexibility of computer-based digital controls, and

3. The retentivity of nonvolatile memory used for the storage of

multiple potentiometer settings or data.

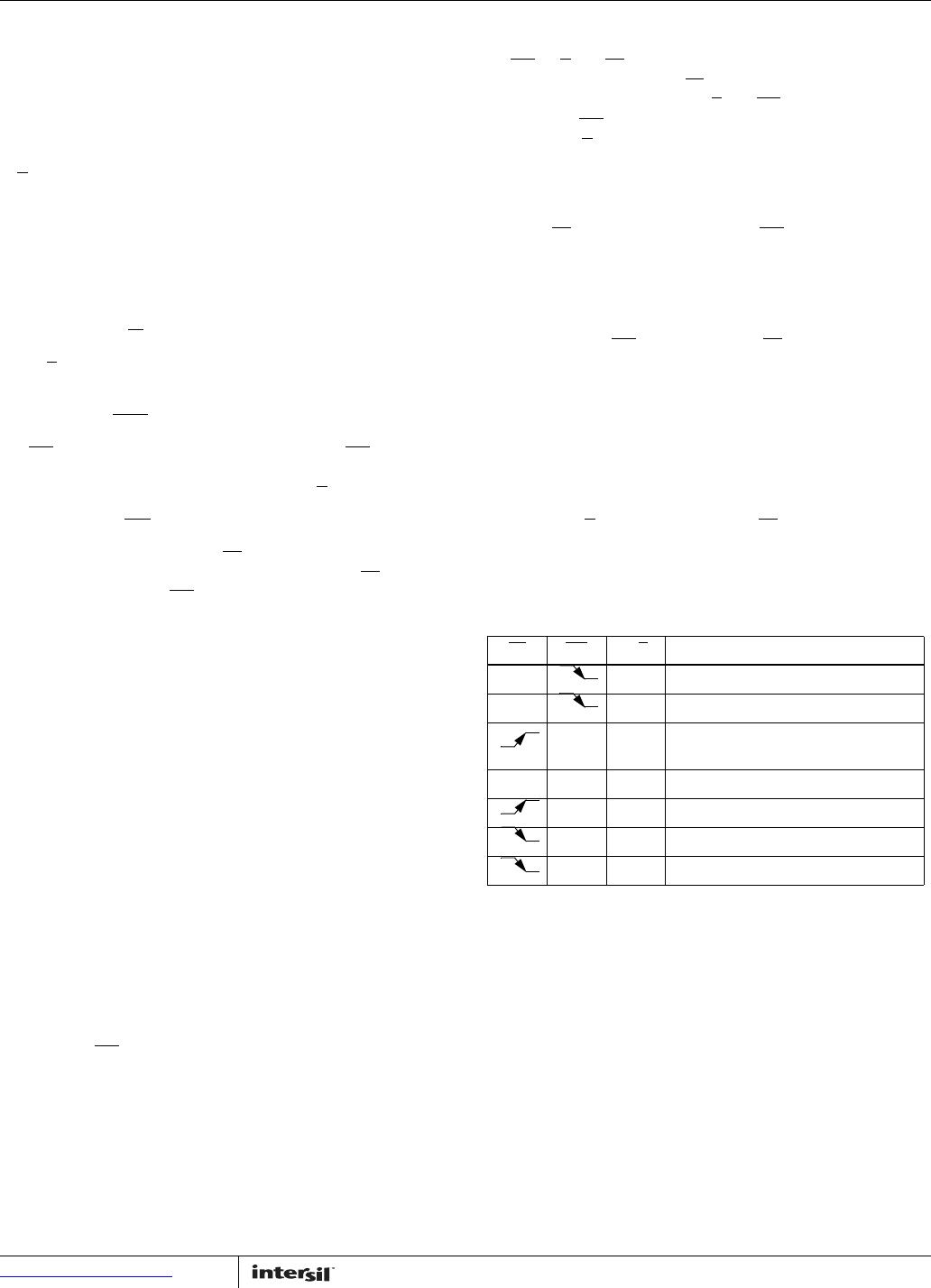

Mode Selection

CS INC U/D MODE

LHWiper up

L L Wiper down

H X Store wiper position to nonvolatile

memory

HXXStandby

L X No store, return to standby

L H Wiper up (not recommended)

L L Wiper down (not recommended)