11

LTC4054-4.2/LTC4054X-4.2

405442xf

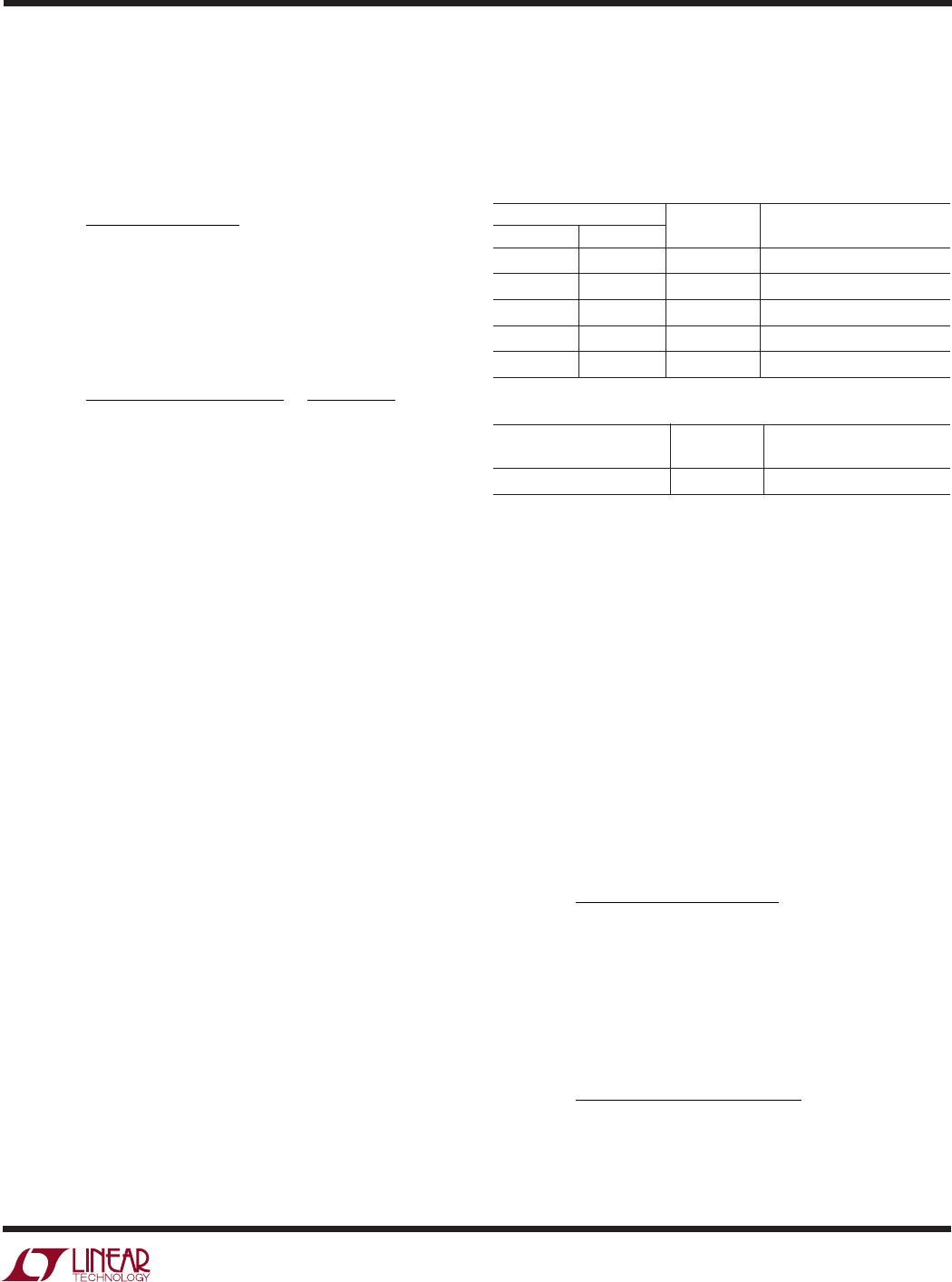

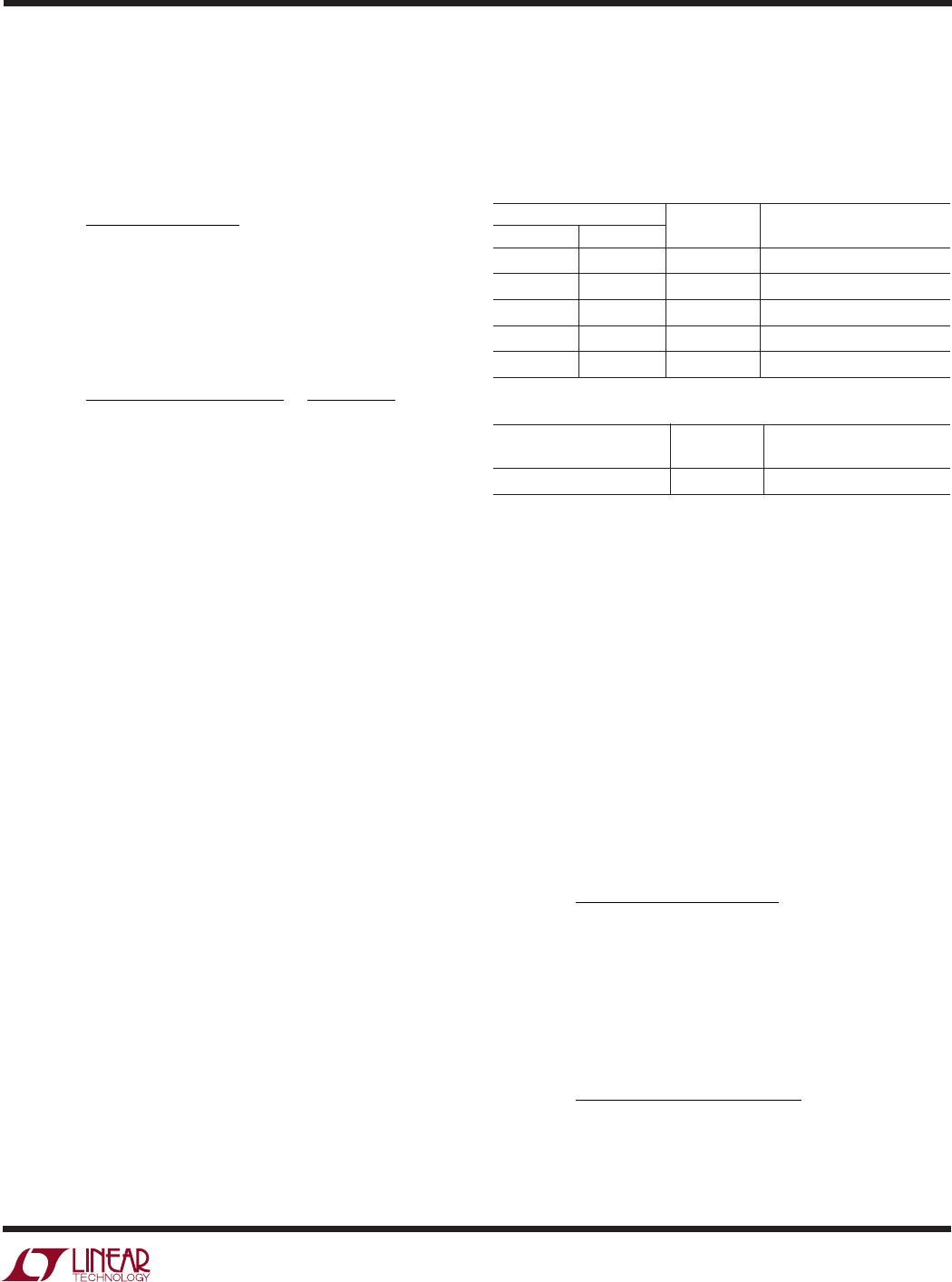

The following table lists thermal resistance for several

different board sizes and copper areas. All measurements

were taken in still air on 3/32" FR-4 board with the device

mounted on topside.

Table 1. Measured Thermal Resistance (2-Layer Board*)

COPPER AREA BOARD THERMAL RESISTANCE

TOPSIDE BACKSIDE AREA JUNCTION-TO-AMBIENT

2500mm

2

2500mm

2

2500mm

2

125°C/W

1000mm

2

2500mm

2

2500mm

2

125°C/W

225mm

2

2500mm

2

2500mm

2

130°C/W

100mm

2

2500mm

2

2500mm

2

135°C/W

50mm

2

2500mm

2

2500mm

2

150°C/W

Table 2. Measured Thermal Resistance (4-Layer Board**)

COPPER AREA BOARD THERMAL RESISTANCE

(EACH SIDE) AREA JUNCTION-TO-AMBIENT

2500mm

2***

2500mm

2

80°C/W

Increasing Thermal Regulation Current

Reducing the voltage drop across the internal MOSFET

can significantly decrease the power dissipation in the IC.

This has the effect of increasing the current delivered to

the battery during thermal regulation. One method is by

dissipating some of the power through an external compo-

nent, such as a resistor or diode.

Example: An LTC4054 operating from a 5V wall adapter is

programmed to supply 800mA full-scale current to a

discharged Li-Ion battery with a voltage of 3.75V. Assum-

ing θ

JA

is 125°C/W, the approximate charge current at an

ambient temperature of 25°C is:

I

CC

VVCW

mA

BAT

=

°°

°

=

120 25

5 3 75 125

608

–

(–. )• /

By dropping voltage across a resistor in series with a 5V

wall adapter (shown in Figure 3), the on-chip power

dissipation can be decreased, thus increasing the ther-

mally regulated charge current

I

CC

VIR V

BAT

S BAT CC BAT JA

=

°°120 25–

(– – )•θ

APPLICATIO S I FOR ATIO

WUUU

The LTC4054 can be used above 45°C ambient, but the

charge current will be reduced from 400mA. The approxi-

mate current at a given ambient temperature can be

approximated by:

I

CT

VV

BAT

A

CC BAT JA

=

°

()

120 –

–•θ

Using the previous example with an ambient temperature

of 60°C, the charge current will be reduced to approxi-

mately:

I

CC

VV CW

C

CA

ImA

BAT

BAT

=

°°

()

°

=

°

°

=

120 60

5 3 75 150

60

187 5

320

–

–. • /

./

Moreover, when thermal feedback reduces the charge

current, the voltage at the PROG pin is also reduced

proportionally as discussed in the Operation section.

It is important to remember that LTC4054 applications do

not need to be designed for worst-case thermal conditions

since the IC will automatically reduce power dissipation

when the junction temperature reaches approximately

120°C.

Thermal Considerations

Because of the small size of the ThinSOT package, it is very

important to use a good thermal PC board layout to

maximize the available charge current. The thermal path

for the heat generated by the IC is from the die to the

copper lead frame, through the package leads, (especially

the ground lead) to the PC board copper. The PC board

copper is the heat sink. The footprint copper pads should

be as wide as possible and expand out to larger copper

areas to spread and dissipate the heat to the surrounding

ambient. Feedthrough vias to inner or backside copper

layers are also useful in improving the overall thermal

performance of the charger. Other heat sources on the

board, not related to the charger, must also be considered

when designing a PC board layout because they will affect

overall temperature rise and the maximum charge current.

*Each layer uses one ounce copper

*Top and bottom layers use two ounce copper, inner layers use one ounce copper.

**10,000mm

2

total copper area