11

LTC1479

OPERATION

U

This scheme allows capacitors and MOSFET switches of

differing sizes and current ratings to be used in the same

system without circuit modifications.

After the transition period has passed, the V

GS

of both

MOSFETs in the selected switch pair rises to approxi-

mately 6V. The gate drive is set at 6V to provide ample

overdrive for logic level MOSFET switches without ex-

ceeding their maximum V

GS

rating.

Internal Power Supplies

Two internal supplies provide power for the control logic

and power source monitoring functions. The V

CCP

logic

supply is approximately 5V and provides power for the

majority of the internal logic circuitry. The V

CC

supply is

approximately 3.60V and provides power for the V

GG

switching regulator control circuitry and the gate drivers.

The V

CC

supply has an undervoltage lockout circuit which

minimizes power consumption in the event of a total loss

of system power; i.e., when all available power sources fall

below approximately 4.5V.

DCIN Voltage Monitoring

The DCIN input is continuously monitored via a two

resistor ladder connected between the DCIN pin and the

DCDIV input. The input threshold is 1.215V (rising edge)

with approximately –35mV hysteresis. The use of a defini-

tive voltage threshold ensures that the DC supply is not

only connected but “healthy” before being attached to the

DC/DC converter input.

Battery Voltage Monitoring

The LTC1479 has the ability to independently monitor both

battery packs. (Because of this, one battery pack may be

discharged as the other is being charged.)

A low-battery detector signals when the selected battery

pack has dropped to the level where a shutdown sequence

should be initiated or the other battery pack engaged.

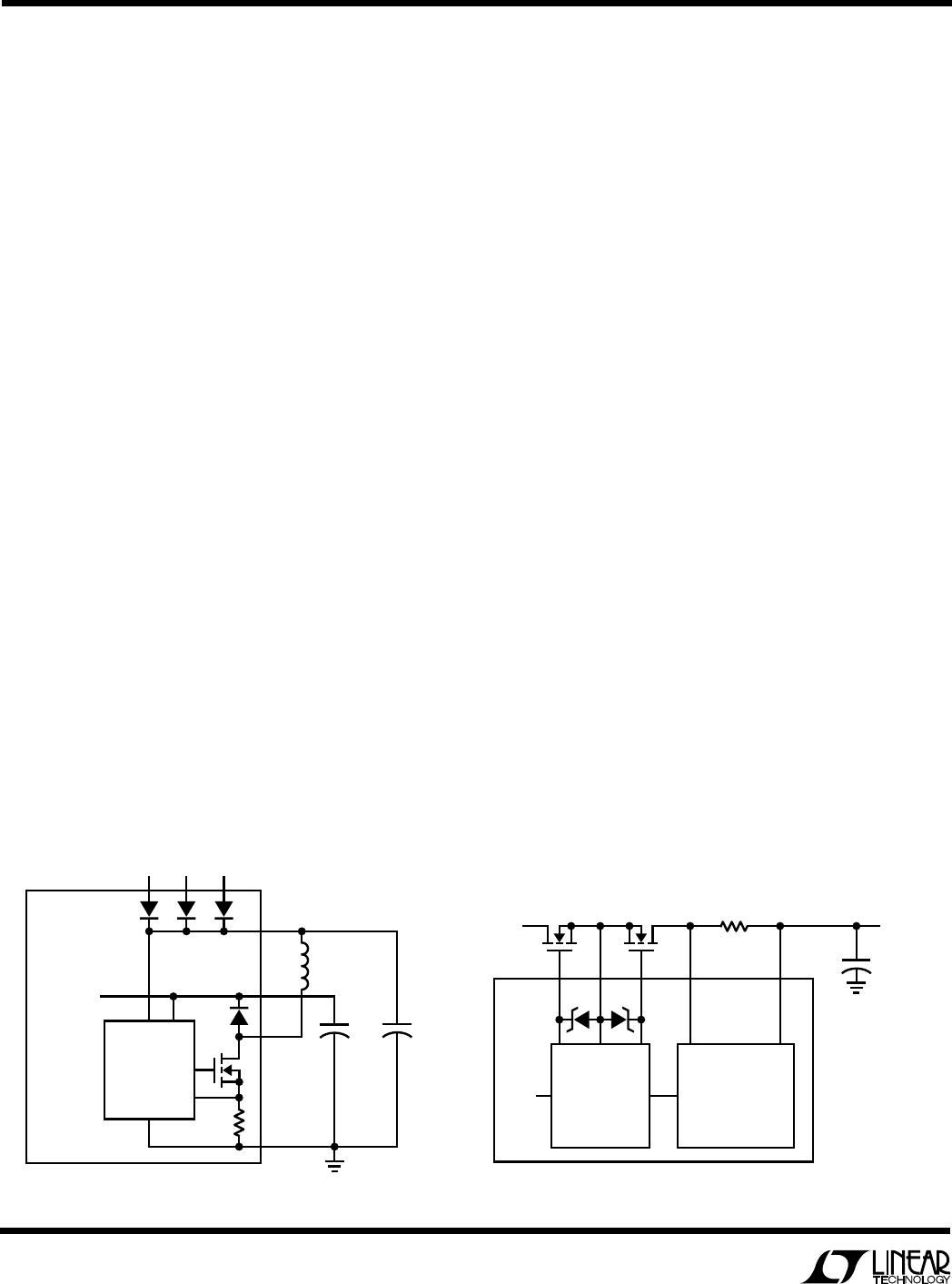

Battery Charging Management Functions

The LTC1479 directly interfaces with LT1510/LT1511

battery charger circuits. Two gate drive circuits control

the two back-to-back N-channel switch pairs, SW G and

SW H, under logic (CHGSEL) control to connect the

output of the charger to the selected battery pack. Break-

before-make action ensures that current does not pass

from one battery pack to the other during switch-over of

the charger output. The CHGSEL input also simulta-

neously switches the positive terminal of the selected

battery pack to the top of the voltage feedback resistor

ladder in the charger system through the CHGMON pin.

Backup Supply Interface

Power for the LTC1479 is obtained from the backup

supply when power is unavailable from the three main

sources of power.

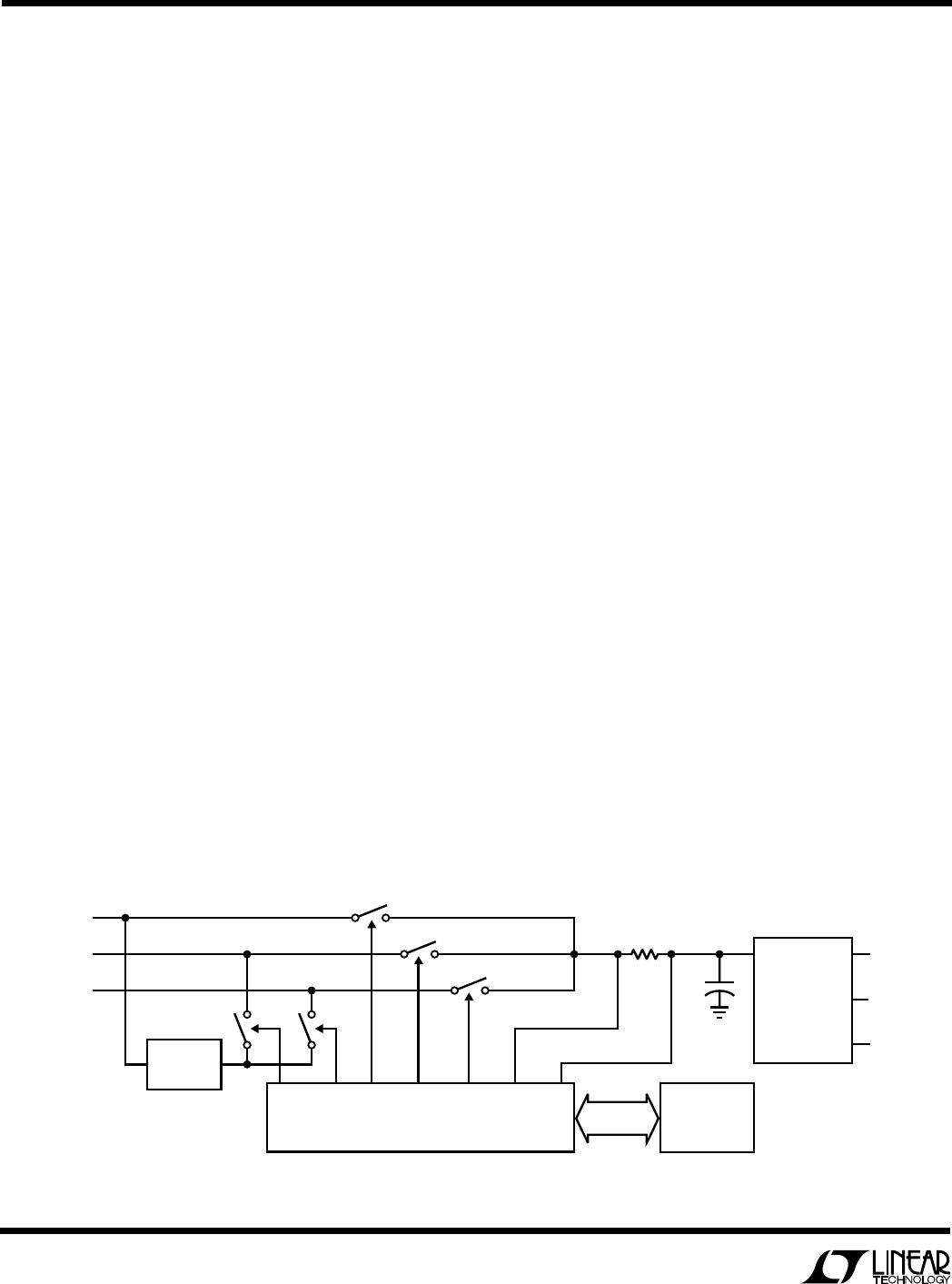

Interface to Companion Microprocessor

A companion µP must be used in conjunction with the

LTC1479 to provide overall control of the power manage-

ment system. The LTC1479 communicates with the µP by

means of five logic inputs and two logic outputs as

described in Table 1.

Table 1. LTC1479 µP Interface Inputs and Outputs

INPUT ACTION

DCIN/BAT Logic High Required to Connect a Good DC Supply

BATDIS Logic Low Disconnects the Battery from the System

BATSEL Selects Which Battery is Connected to the System

(Logic High Selects BAT1; Logic Low Selects BAT2)

CHGSEL Selects Which Battery is Charged and Monitored

(Logic High Selects BAT1; Logic Low Selects BAT2)

3DM Forces the Main Three Power Path Switches Into

“3-Diode Mode.” See Applications Information Section

OUTPUT ACTION

DCINGOOD Logic High When a Good DC Supply is Present

LOBAT Logic Low When Selected Battery Voltage is Low